Order your custom plastic parts.

Online Injection Molding service

Obtain custom plastic prototypes and high-quality production parts. Request free quotes for injection molding today!

- Get free and automatic DFM feedback.

- Typically injection molding: 3 days

- T1 sample as fast as 2 weeks

On Demand Injection Molding Service

We produce high-quality plastic molded parts of any size or complexity, using both thermoplastics and thermosets. Our manufacturing meets ISO 9001-C or tighter tolerances.

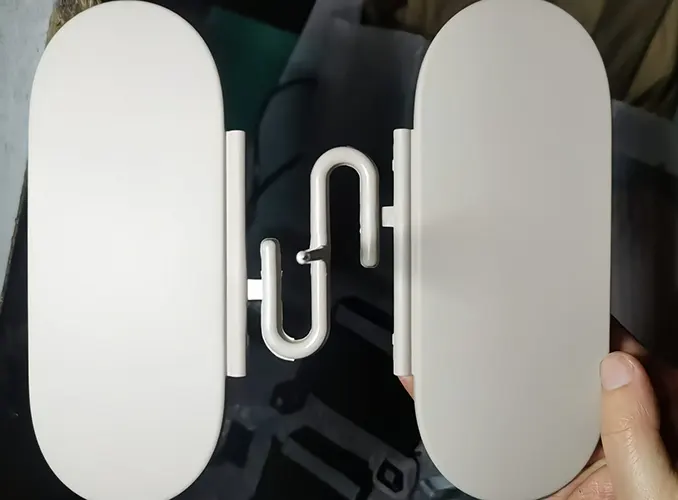

Plastic injection molding

Plastic injection molding is the most widely used method for mass-producing plastic products. The process involves melting plastic, injecting it into a mold, allowing it to solidify, ejecting the finished product, and repeating the cycle.

Over molding

We are provide over molding services that means one material is molded over another to create a single, integrated component. It typically involves molding a soft material, over a rigid plastic or metal substrate to enhance grip, durability, or aesthetics.

Insert molding

Insert molding is a manufacturing process where a preformed component, typically metal or another material, is placed into a mold before injecting plastic around it. This creates a single, integrated part with enhanced strength, durability, and functionality.

Why Choose ours Injection Molding Service?

delivering exceptional results through experience, dedication, and strategic thinking.

working closely with clients to understand their unique needs and goals

featuring the latest technology and advanced machinery to ensure precision, efficiency.

leveraging cutting-edge technology to manufacture intricate components

delivering exceptional value without compromising on quality or precision.

ensuring fast, efficient, and reliable production without compromising quality.

Capabilities of injection molding Services

We provide top-quality plastic injection molding services, delivering high-precision, finely finished parts at competitive prices.

Maximum Part:1200×1000×500 mm

Manimum Part: 5×5×5 mm

Single-cavity molds, multi-cavity molds,

family molds

+/- 0.1 mm

0.5 mm to 5 mm

0.5° to 2°

Most orders can be completed within 15 working days

Design Guidelines

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in injection molding service

Wall Thickness

2. Recommended thickness: 0.8 mm – 4 mm, depending on material.

3. Gradual transitions between different thicknesses help avoid defects..

Draft Angles

2. Typical draft angle: 1°–3° per side, more for textured surfaces.

Ribs & Gussets

2. Rib thickness: 40–60% of the main wall thickness.

3. Add gussets for additional reinforcement.

Fillets & Radii

2. Recommended inside radius: at least 0.5 times the wall thickness.

Bosses (for Screws & Fasteners)

2. Wall thickness of the boss should be no more than 60% of the main part thickness.

Undercuts & Side Actions

2. If unavoidable, use side actions or lifters in the mold.

Gate Placement

2. Avoid placing gates near weak or cosmetic areas to prevent defects.

Tolerance Considerations

2. Critical dimensions should allow slight variations to improve manufacturability.

Materials for Injection Molding

We source high-quality raw materials, offering over 50 types of thermoplastics and thermosetting plastics for injection molding. Our materials cater to various industries, including medical, new energy, consumer electronics, and daily essentials.

Customers can confidently select the right materials and focus on product manufacturing.

Rigid Materials

Tipical: ABS, ABS+PC, LCP, Nylon 6, Nylon 66, Nylon 11, Nylon 12, PBT, PC, PE, PEI, LDPE, HDPE, PET, PP and etc

Elastic Materials

Tipical: EPDM, PEBA, TPE, TPU, TPV, LSR and etc.

Surface Finishes

We provide SPI surface finishes for injection-molded parts. Our experts are ready to help you select the ideal finish for your project.

| Name | SPI | Guide | R.A Value | Applications | Material |

|---|---|---|---|---|---|

| Glossy | A1 | Grade #3 Diamond | 0-1 | Lens / Mirror – requires 420 SS material | Acrylic |

| Glossy | A2 | Grade #6 Diamond | 1-2 | High-gloss polished parts. | Acrylic, PC |

| Glossy | A3 | Grade #15 Diamond | 2-3 | High-gloss polished parts. | ABS, Acrylic. PS, Nylon, PC |

| Semi-glossy | B1 | 600 Grit paper | 2-3 | Medium Polish | ABS, Acrylic, PP. PS, HDPE, Nylon, PC |

| Semi-glossy | B2 | 400 Grit paper | 4-5 | Medium Polish | ABS, Acrylic, PP. PS, HDPE, Nylon, PC |

| Semi-glossy | B3 | 320 Grit paper | 9-10 | Med – Low polish | ABS, Acrylic, PP. PS, HDPE, Nylon |

| Matte | C1 | 600 Stone | 10-12 | Low Polish | ABS, Acrylic, PP. PS, HDPE, Nylon, TPU |

| Matte | C2 | 400 Stone | 25-28 | Low Polish | ABS, Acrylic, PP. PS, HDPE, Nylon, TPU |

| Matte | C3 | 320 Stone | 38-42 | Low Polish | ABS, Acrylic, PP. PS, HDPE, Nylon, TPU |

| Textured | D1 | Dry Blast Glass Bead | 10-12 | Satin finish | ABS, PP. PS, HDPE, Nylon, PC, TPU |

| Textured | D2 | Dry Blast # 240 Oxide | 26-32 | Dull Finish | ABS, PP. PS, HDPE, Nylon, TPU |

| Textured | D3 | Dry Blast # 24 Oxide | 190-230 | Dull Finish | ABS, PP. PS, HDPE, Nylon, TPU |

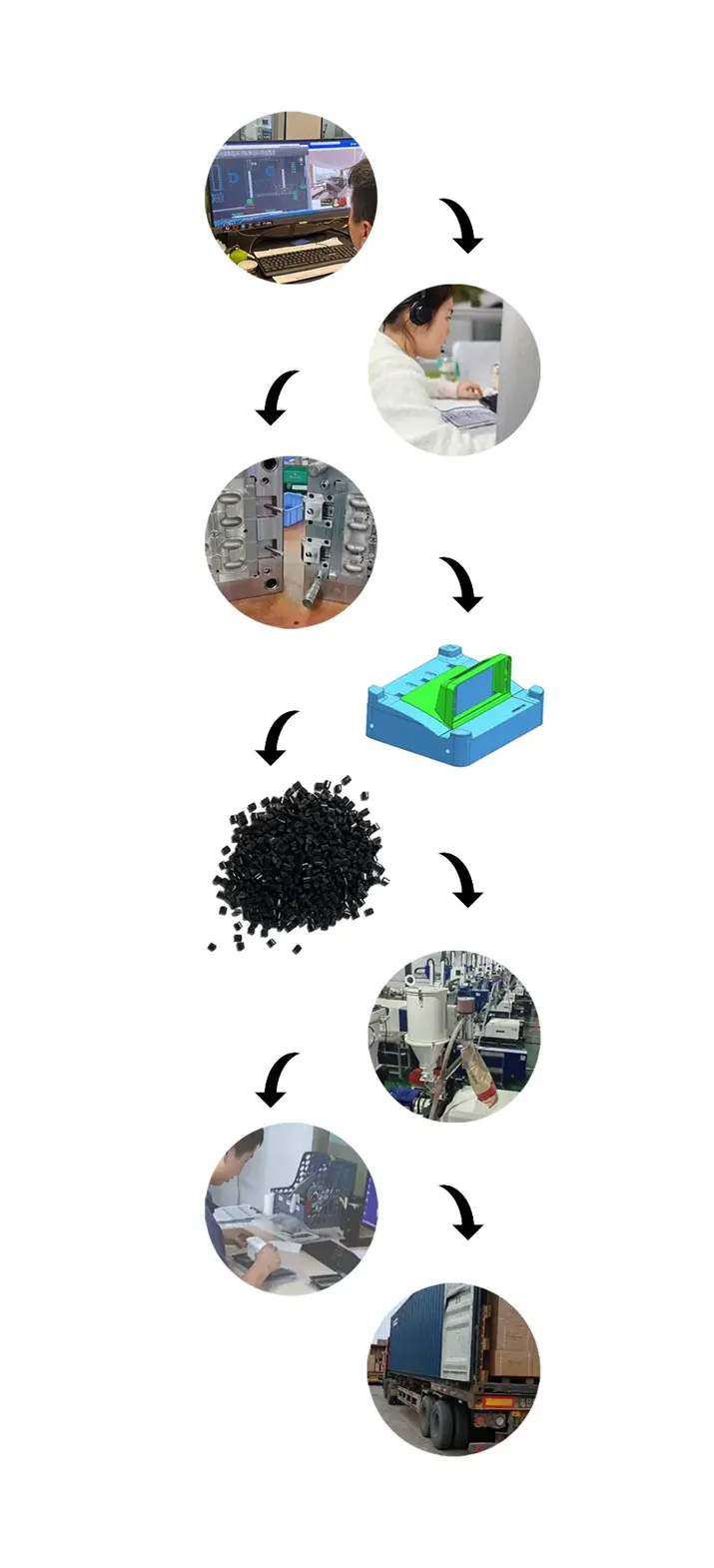

Process Work

We simplify your order process, from online quotes to precision mold making and production-ready plastic parts. With our expert team and advanced machinery, we ensure efficiency and on-time delivery.

01

Upload Design File

Upload your 3D CAD files and 2D drawings to our platform to initiate precise custom molding.

02

Quotation

Select your materials, surface finishes, and shipping options to receive a detailed quote.

03

Place an order

Customer place an order include qty, price, delivery date, and other business.

04

DFM

Customer receive manufacturability feedback within 24 hours.

05

Make the mold

Arrange production mold, ensure quality

06

T0 (first time test molding)

check that it matches drawings, tolerance, color, and adjust mold and injection process.

07

T1 (second test molding)

Verify if the issue is resolved and make further adjustments if needed.

08

Confirm samples

Obtain customer approval to ensure every detail meets the specifications.

09

Manufacturing

Once you approve the T1 sample, we begin full-scale production, ensuring high quality and precision throughout.

10

Deliver

We deliver your parts directly to your doorstep, ensuring they are ready for immediate use.

FAQ

We provide SPI surface finishes for injection-molded parts. Our experts are ready to help you select the ideal finish for your project.

What types of plastic materials do you offer for injection molding?

We provide over 50 types of thermoplastics and thermosetting plastics, including ABS, PC, PP, PEEK, Nylon, TPU, and more, suitable for various industries such as medical, automotive, and consumer electronics.

Can you assist with material selection for my project?

Yes! Our experts can recommend the best material based on your product’s functionality, durability, and cost requirements.

What surface finishes do you offer for injection-molded parts?

We offer SPI surface finishes, including high-gloss, matte, textured, and custom finishes, to meet your aesthetic and functional needs.

How do I get a quote for my injection molding project?

Simply upload your 3D CAD files and 2D drawings to our platform, select materials and surface finishes, and receive a detailed quote within 24 hours.

Do you provide Design for Manufacturability (DFM) analysis?

Yes, we offer free and automatic DFM feedback within one day to optimize your design for cost-effective and high-quality production.

What is the typical lead time for injection molding production?

Lead times vary based on project complexity, but T1 samples are typically ready within 2–4 weeks, with full-scale production following approval.

Can you handle low-volume and high-volume production?

Yes, we specialize in both low-volume prototype runs and high-volume mass production, ensuring cost-effective solutions at any scale.

What industries do you serve?

We provide injection molding services for industries including medical, automotive, aerospace, consumer electronics, new energy, and daily necessities.

Do you offer secondary processing and assembly?

Yes, we provide additional services such as overmolding, insert molding, ultrasonic welding, painting, and assembly to meet your complete manufacturing needs.

How do you ensure quality control in production?

We follow strict quality control measures, including ISO 9001 standards, in-process inspections, and final product testing to ensure every part meets your specifications.

Blog

Welcome to our blog, where we share insights into various manufacturing processes.