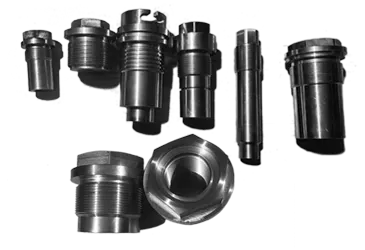

Custom Online Mild Steel CNC machining services for you

Mild Steel CNC machining services

- 24/7 machining ensures we’re always ready to deliver

- Tolerances up to ±0.0004″ (0.01mm)

- Lead times as short as 1 day.

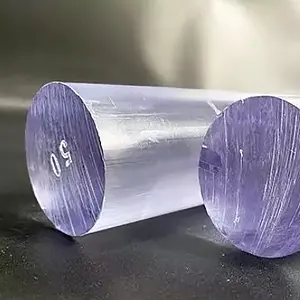

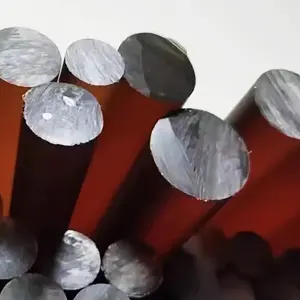

Overview of Mild Steel in manufacturing

Our Custom Online Mild Steel CNC Fabrication Service provides tight-tolerance processing for Mild Steel parts, guaranteeing outstanding exactness and craftsmanship. Using advanced CNC equipment, we efficiently machine challenging geometries while offering quick delivery schedules and customized services tailored to meet your precise job needs.

《 Properties

Carbon steel is a common material choice in CNC machining, valued for its strength and adaptability across different applications. Its hardness makes it suitable for producing tools and mechanical parts that must withstand heavy use. The ease of machining carbon steel, however, depends on how much carbon it contains—steels with higher carbon levels tend to be tougher and more resistant to cutting, which can complicate the machining process..

Parameters

When working with carbon steel, selecting the right cutting parameters and tools is essential. Low-carbon grades allow for faster machining with higher speeds and feeds. In contrast, high-carbon variants demand a more cautious approach—slower speeds and careful monitoring of tool wear. To handle the demands of harder steel, tools made from carbide or high-speed steel are generally recommended, as they maintain performance under tougher conditions.

Precautions

Effective temperature control is key when machining carbon steel, as too much heat can quickly wear down tools or alter the shape of the part. Applying coolant correctly helps manage this heat. It’s also important to keep chips from piling up, since poor chip evacuation can harm the surface of the workpiece. Choosing tools with suitable materials and shapes plays a big role in ensuring long tool life and reliable cutting performance.

Why Mild steel is ideal for CNC machining?

Mild steel is considered ideal for CNC machining due to its versatility, affordability, and ease of machining. This type of steel has a low carbon content, making it softer and more malleable than other types of steel. This allows for smoother and more precise cuts during the CNC machining process. Additionally, mild steel is readily available in a variety of shapes and sizes, making it a cost-effective option for manufacturing projects. Its inherent strength and durability also make it suitable for a wide range of industrial applications. Overall, mild steel's properties make it a popular choice for CNC machining projects.

Benefits of working with Mild steel at TONZA

Working with Mild Steel at TONZA offers numerous benefits to professionals in various industries. Mild steel is known for its durability, strength, and versatility, making it an ideal choice for a wide range of applications. Its malleability allows for easy shaping and forming, while its cost-effectiveness makes it a popular option for budget-conscious projects. Mild steel also boasts good weldability and machinability, making it a practical choice for fabrication processes. At TONZA, we ensure top-quality mild steel products that meet industry standards and exceed customer expectations.

Why Choose ours Mild Steel CNC machining services?

Each piece is produced to tight tolerances of ±0.01 mm, guaranteeing a flawless alignment to design.

We work with reliable material suppliers to provide high-quality quality materials for your components.

Get quick and exact DFM reviews to enhance your plan for production and accelerate output.

With in-depth market knowledge, we offer reliable the substance CNC fabrication options.

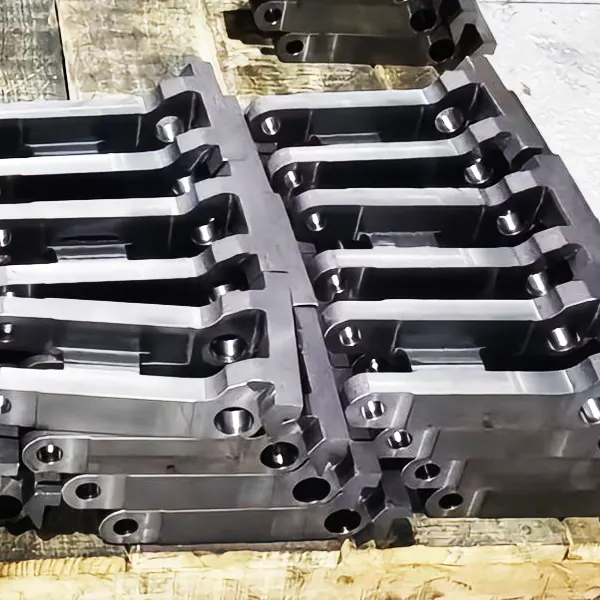

Capabilities of Mild Steel CNC machining services

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

Tolerances

±0.05mm

Premium-grade tech solutions to provide you with reliable quality you can trust.

Max part size

500 mm x 500 mm

Elegantly designed innovation to provide you with crafted for superior durability.

Min part size

5 mm x 5 mm

Vast practical knowledge, expertise in producing sophisticated parts.

Lead Time

< 10 days

Strong and structured management system, and fast and efficient production cycles

Surface Finish

Ra 0.8-1.6 µm

Efficient group supervision, and maximized production.

Wall Thickness

0.75 mm

Well-versed in the field, skilled in managing intricate product designs.

Typical of Mild Steel Material

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in CNC machining.

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Fatigue Strength (MPa) | Elongation (%) | Hardness (HRC) | Density (g/cm³) | Applications |

|---|---|---|---|---|---|---|---|

| AISI 1005 | 340–420 | 210–280 | ~150 | 25–30 | <10 | 7.87 | Wire, deep-drawn parts, fasteners |

| AISI 1008 | 370–440 | 220–310 | ~160 | 28–34 | <12 | 7.87 | Automotive panels, stamping, tubing |

| AISI 1010 | 380–460 | 240–320 | ~170 | 25–30 | 10–15 | 7.87 | Cold-formed parts, structural sheets |

| AISI 1015 | 400–480 | 250–340 | ~180 | 20–25 | 12–18 | 7.87 | Gears, shafts, automotive hardware |

| AISI 1018 | 440–470 | 370–400 | ~240 | 15–25 | 12–20 | 7.87 | CNC machined parts, shafts, rods, bolts |

| A36 (Structural Steel) | 400–550 | 250–400 | ~200 | 20–23 | 10–18 | 7.85 | Construction beams, plates, structural applications |

Commonly Used Mild Steel Types

Our CNC systems offer precision tolerances that satisfy market standards, ensuring uniform exactness and flawless piece fit.

| Parameter | Typical Value (Roughing) | Typical Value (Finishing) | Notes |

|---|---|---|---|

| Spindle Power | 5–15 kW | 3–10 kW | Depends on machine type and material volume |

| Spindle Speed (RPM) | 500–1,500 RPM | 1,500–3,000 RPM | Higher speeds for smaller tools or finishing passes |

| Feed Rate (mm/min) | 300–1,200 mm/min | 150–600 mm/min | Based on tool diameter and depth of cut |

| Cutting Depth (mm) | 2–4 mm (rough cut) | 0.5–1 mm (finish cut) | Avoid deep cuts in one pass; may cause vibration or deflection |

| Cutting Width (mm) | 50–70% of tool diameter | 10–30% of tool diameter | Light engagement for better surface finish |

| Cutting Tool Material | Carbide (preferred), HSS (acceptable) | Coated carbide for better wear resistance | TiAlN/TiCN coatings recommended |

| Tool Path Strategy | Climb milling, trochoidal milling | Climb milling or contour finishing | Trochoidal milling helps reduce heat and wear |

| Coolant Type | Water-soluble coolant (emulsion type) | Same as roughing | Helps with heat dissipation and chip evacuation |

| Cutting Fluid Flow Rate | 8–12 L/min | 6–10 L/min | Maintain steady flow to avoid overheating |

| Pitch (mm/tooth) | 0.05–0.2 mm/tooth | 0.01–0.08 mm/tooth | Adjust depending on tool and rigidity |

| Tool Wear Rate | Moderate | Lower with sharp tools and proper cooling | Monitor tool condition regularly |

| Surface Finish (Ra µm) | 1.6–3.2 Ra | 0.8–1.6 Ra | For finer finish, consider polishing or grinding |

Surface Treatment of Mild Steel

We ensure a large assortment of CNC materials for individually crafted parts, including cooper, brass, steel, plastics, aluminum, and over 100 other materials.

Brushing

Polishing

Tumbling

Anodizing

Black Oxide

Electroplating

Powder Coating

Alodine

Passivation

Electroless Plating

Application Industries of Mild Steel

From automotive to aircraft, Tonza’s CNC milling satisfies the precise needs of various industries. We work with individual innovators, designers, and enterprise organizations, serving over 1,000 partners worldwide.

Choice Other Metal Materials Machining

Our CNC machining services ensure precision tolerances for repeatable precision and flawless part compatibility.

Brass CNC machining services

Cooper CNC Machining Service

Aluminum CNC Machining Service

Stainless Steel CNC Machining Services

Mild Steel CNC Machining Services

Magnesium CNC Machining Services

Titanium CNC Machining Services

Choice Other Plastics Materials Machining

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

ABS CNC machining services

PMMA CNC Machining Service

Nylon CNC Machining Service

PC CNC Machining Service

PP CNC Machining Services

PET CNC Machining Services

PEI CNC Machining Services

POM CNC Machining Services

PTFE CNC Machining Services

PEEK CNC Machining Services

HDPE CNC Machining Services

UHMW CNC Machining Services

FAQ about Mild Steel

For a clearer understanding of what we offer, here are FAQs on our Mild Steel CNC machining process.

TONZA works with popular mild steel grades such as A36, 1018, 1020, and S275, ensuring excellent machinability and reliable mechanical properties.

TONZA combines high-performance CNC machines and experienced engineers to deliver accurate, durable, and cost-effective mild steel parts.

TONZA regularly achieves tolerances of ±0.05 mm, with even tighter tolerances possible depending on your part's design and function.

Yes, TONZA can coordinate heat treatment processes such as annealing, normalizing, or case hardening to improve strength and wear resistance of mild steel parts.

TONZA supports everything from single-unit prototyping to low- and mid-volume production, offering flexibility to meet your project timeline and budget.

TONZA offers a range of finishes including zinc plating, black oxide, powder coating, sandblasting, and painting to enhance corrosion resistance and aesthetics.

TONZA applies protective coatings, rust inhibitors, and proper post-machining cleaning to minimize oxidation and extend the part's lifespan.

Yes, TONZA’s CNC machining centers can accommodate large-format and thick-section mild steel components with excellent stability and accuracy.

TONZA serves industries such as construction, heavy machinery, industrial equipment, and transportation, where strength and durability are essential.

Yes, TONZA offers threading, tapping, and installation of threaded inserts for mild steel parts used in structural or mechanical assemblies.

TONZA typically delivers mild steel parts in 5 to 10 business days, with faster lead times available for urgent or time-sensitive orders.

TONZA accepts STEP, IGES, STL, DWG, and DXF files, allowing for fast and accurate quoting and manufacturing.

Yes, TONZA offers Design for Manufacturing (DFM) support to help optimize your mild steel part design for machining efficiency and cost-effectiveness.

TONZA uses precision tooling, controlled speeds, and finishing processes to produce smooth, burr-free surfaces on mild steel components.

To receive a quote, upload your CAD files and project details to the TONZA website, and our team will respond with a detailed estimate within 24 hours.