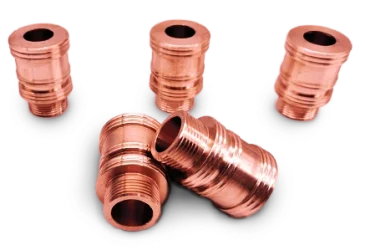

Reliable Cooper CNC machining services for you

Cooper CNC machining services

- Our in-house workshop runs 24/7 to accelerate delivery

- Tolerances up to ±0.0004″ (0.01mm)

- Lead times as short as 1 day.

Overview of Cooper in manufacturing

Our Custom Online Copper CNC Machining Service delivers high-precision machining for copper parts, guaranteeing exceptional accuracy and quality. Using advanced CNC technology, we expertly handle complex designs while offering fast turnaround times and customized solutions tailored to meet your specific project requirements.

Properties

Parameters

Precautions

Why Cooper is ideal for CNC machining?

Copper is an ideal material for CNC machining thanks to its excellent thermal and electrical conductivity, superior corrosion resistance, and good machinability. Its softness allows for highly precise and detailed cuts, while its strength ensures durable, high-performance parts. Copper’s natural ability to resist wear and corrosion makes it perfect for electrical components, heat exchangers, and precision industrial parts.

With the right tooling and setup, copper can achieve outstanding surface finishes and tight tolerances, making it a top choice across industries like aerospace, electronics, and automotive.

Benefits of working with copper at TONZA

At TONZA, we maximize the advantages of copper to deliver high-quality, precision components for a wide range of industries. Copper’s excellent electrical and thermal conductivity, along with its strong corrosion resistance and machinability, makes it an ideal material for demanding applications.

With advanced CNC technology and a skilled engineering team, we transform complex copper designs into reliable, high-performance parts. Working with TONZA ensures custom solutions, fast turnaround times, and consistent quality to meet your project needs.

Why Choose Ours Cooper CNC Machining Services?

Each part is manufactured to tight tolerances of ±0.01 mm, guaranteeing a perfect fit to design.

Use high-grade copper materials to maximize thermal and electrical conductivity.

Get fast and accurate DFM reviews to optimize your design for manufacturing and speed up production.

Benefit from our rich machining experience with rapid DFM reviews to streamline your design and production process.

Capabilities of Cooper CNC Machining Services

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

Tolerances

±0.05mm

Sophisticated technological craftsmanship to provide you with reliable quality you can trust.

Max part size

500 mm x 500 mm

Backed by modern and precise equipment, tailored solutions to customer requirements

Min part size

5 mm x 5 mm

Extensive hands-on experience, expertise in producing sophisticated components.

Lead Time

< 10 days

Well-coordinated team management, and maximized manufacturing output

Surface Finish

Ra 0.8-1.6 µm

Well-coordinated team management, and maximized manufacturing output

Wall Thickness

0.75 mm

Extensive hands-on experience, expertise in producing sophisticated components.

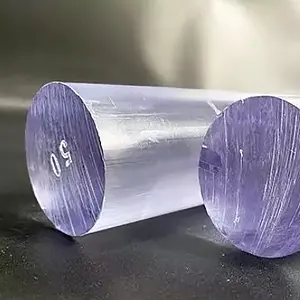

Cooper Material Properties

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in CNC machining.

| Grade | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (Rockwell) | Electrical Conductivity (% IACS) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|---|

| C11000 | 210 (annealed) | 33 (annealed) | B45 (annealed) | ~100–101% | ~390–400 |

| C10100 | 220 (annealed) | 40 (annealed) | B40 (annealed) | ~101% | ~391 |

| C14500 | 275–370 | 69–207 | B60–B75 | ~90–95% | ~340–360 |

| C14700 | 240–350 | 55–200 | B55–B70 | ~90–95% | ~340–360 |

| C17200 | 480–1380 (after heat treatment) | 345–1170 (after heat treatment) | C35–C45 (hardened) | ~22–30% | ~105–130 |

| C17500 | 415–965 (after heat treatment) | 275–690 (after heat treatment) | C30–C40 (hardened) | ~45–60% | ~170–210 |

Commonly Used Cooper Types

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

| Grade | Name | Conductivity (% IACS) | Notes |

|---|---|---|---|

| C10100 | Oxygen-Free Electronic (OFE) Copper | ~101% | Highest purity copper; used for high-end electrical applications. |

| C10200 | Oxygen-Free Copper (OF) | ~100% | Very low oxygen content; excellent conductivity. |

| C11000 | Electrolytic Tough Pitch (ETP) Copper | ~100% | Standard electrical-grade copper; slightly more oxygen (~0.04%). |

| C12200 | Phosphorus-Deoxidized Copper | ~97% | Used for plumbing; slightly lower conductivity due to phosphorus. |

| C14500 | Tellurium Copper | ~90–95% | Modified for machinability; slight conductivity sacrifice. |

| C14700 | Sulfur Copper | ~90–95% | Good machinability and decent conductivity. |

| Grade | Name | Conductivity (% IACS) | Notes |

|---|---|---|---|

| C14500 | Tellurium Copper | ~85–90% (compared to free-cutting brass = 100%) | Best machinability among copper grades; easy to machine without sacrificing much conductivity. |

| C14700 | Sulfur Copper | ~80–85% | Good machinability; slightly less conductive than pure copper. |

| C17200 | Beryllium Copper | ~20–40% | Good machinability after aging; excellent strength & wear resistance. |

| C17500 | Beryllium-Nickel Copper | ~30–50% | Used for plumbing; slightly lower conductivity due to phosphorus. |

| C11000 | (ETP) Copper | ~20–25% | Poor machinability; soft and gummy during cutting. |

| C10100 | (OFE) Copper | ~20–25% | Very poor machinability; extremely pure and soft. |

| Grade | Name | Conductivity | Notes |

|---|---|---|---|

| C17200 | Beryllium Copper | Excellent | Outstanding resistance to corrosion, especially in marine and industrial environments; |

| C17500 | Beryllium-Nickel Copper | Excellent | Excellent corrosion and fatigue resistance; good for demanding environments. |

| C10100 | (OFE) Cooper | Excellent | Very pure, highly resistant to oxidation and corrosion, especially in vacuum and controlled atmospheres. |

| C11000 | (ETP) Copper | Very Good | Good general corrosion resistance, but slightly sensitive to oxidizing acids and industrial atmospheres. |

| C14500 | Tellurium Copper | Very Good | Good corrosion resistance, similar to C11000; better machinability. |

| C14700 | Sulfur Copper | Good | Fairly good corrosion resistance but not as high as pure copper types. |

| Grade | Name | Conductivity | Notes |

|---|---|---|---|

| C17200 | Beryllium Copper | Extremely High | After heat treatment (age hardening), tensile strength can reach up to 1380 MPa; excellent wear, fatigue, and impact resistance. |

| C17500 | Beryllium-Nickel Copper | Very High | Slightly lower strength than C17200 but better electrical conductivity; very good wear and fatigue resistance. |

| C18200 | Chromium Copper | High | Good strength, high hardness, excellent resistance to wear and deformation under high temperatures; often used for welding electrodes. |

| C15000 | Zirconium Copper | High | Good strength and softening resistance at elevated temperatures; good wear resistance. |

| C14500 | Tellurium Copper | Moderate | Primarily designed for machinability, but offers better strength and wear resistance than pure copper. |

| C11000 | (ETP) Copper | Low | Soft, easily worn; not intended for high-wear applications. |

Surface Treatment

We offer a wide range of CNC materials for custom parts, including aluminum, steel, brass, plastics, and over 100 other materials.

Brushing

Polishing

Tumbling

Anodizing

Black Oxide

Electroplating

Powder Coating

Alodine

Passivation

Electroless Plating

Application Industries

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in CNC machining.

Choice Other Metal Materials Machining

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

Brass CNC machining services

Cooper CNC Machining Service

Aluminum CNC Machining Service

Stainless Steel CNC Machining Services

Mild Steel CNC Machining Services

Magnesium CNC Machining Services

Titanium CNC Machining Services

Choice Other Plastics Materials Machining

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

ABS CNC machining services

PMMA CNC Machining Service

Nylon CNC Machining Service

PC CNC Machining Service

PP CNC Machining Services

PET CNC Machining Services

PEI CNC Machining Services

POM CNC Machining Services

PTFE CNC Machining Services

PEEK CNC Machining Services

HDPE CNC Machining Services

UHMW CNC Machining Services

FAQ

To help you better understand our copper CNC capabilities, we’ve answered the most frequently asked questions.

TONZA machines a wide range of copper grades including C110 (electrolytic tough pitch), C101 (oxygen-free copper), and brass alloys, depending on your conductivity and mechanical requirements.

TONZA combines precision CNC technology and experienced technicians to deliver high-accuracy copper components for electrical, thermal, and mechanical applications.

TONZA regularly achieves tolerances of ±0.05 mm, with finer tolerances down to ±0.01 mm available for demanding copper components.

Yes, TONZA provides deburring, polishing, and plating options such as nickel, tin, or gold plating to protect and enhance the surface of copper parts.

Yes, TONZA uses optimized tool paths, sharp cutters, and coolant strategies to prevent burring, tearing, or work hardening during copper machining.

Absolutely. TONZA machines pure copper and copper alloys like brass and bronze, each with tailored feeds and speeds for maximum precision.

TONZA applies specialized cooling and chip evacuation strategies to manage copper’s high thermal conductivity and maintain dimensional accuracy.

TONZA serves industries like electronics, aerospace, energy, and medical that require high-conductivity copper parts with tight tolerances.

Yes, TONZA’s multi-axis CNC machines are ideal for producing detailed copper components, including fine channels, pockets, and threads.

TONZA can precisely tap threads or install threaded inserts into copper parts, making them assembly-ready with minimal post-processing.

TONZA typically delivers copper components within 5–10 business days, with expedited options available for urgent orders.

Yes, TONZA supports rapid prototyping as well as low- to mid-volume production, allowing for flexible copper part development.

TONZA recommends avoiding thin walls or deep pockets in pure copper and offers DFM (Design for Manufacturing) support to improve machinability and cost.

Upload your CAD files to the TONZA website, specify material and quantity, and get a fast, customized quote within 24 hours.

TONZA delivers exceptional precision, expert DFM advice, high-conductivity materials, and reliable turnaround, making us a trusted partner for copper machining needs.