Custom Online Aluminum CNC machining services for you

Aluminum CNC machining services

- Our fully operational machine shop delivers speed and flexibility

- Tolerances up to ±0.0004″ (0.01mm)

- Lead times as short as 1 day.

Overview of Aluminum in manufacturing

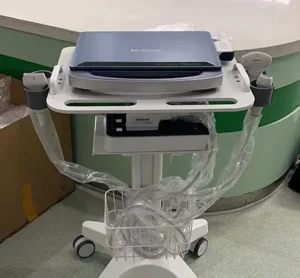

Tonza’s Custom Online Aluminum CNC Milling Service provides tight-tolerance manufacturing for Aluminum parts, promising exceptional precision and performance. Using state-of-the-art CNC technology, we efficiently machine intricate structures while providing quick turnaround times and tailored services tailored to meet your specific job requirements.

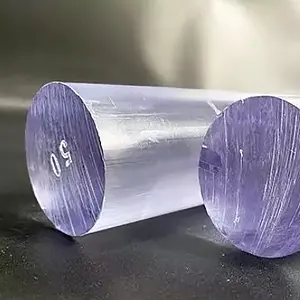

Properties

Aluminum is a lightweight and versatile metal known for its excellent corrosion resistance. It is non-toxic, non-magnetic, and non-sparking, making it ideal for a wide range of applications. Aluminum also boasts high thermal and electrical conductivity, as well as being easily recyclable. Its strength-to-weight ratio is impressive, making it a popular choice for industries such as transportation, construction, and packaging.

Parameters

The main parameters of Aluminum include its atomic number of 13, atomic mass of 26.98 g/mol, melting point of 660.32°C, density of 2.70 g/cm³, and a symbol of Al. Aluminum is a silvery-white, ductile metal with excellent corrosion resistance, making it ideal for a wide range of applications in various industries such as construction, aerospace, automotive, and packaging.

Precautions

When machining aluminum, it is important to wear appropriate personal protective equipment, such as safety goggles and gloves, to prevent injury. Use lubrication to keep the tool cool and prevent overheating. Make sure to secure the aluminum properly to avoid accidents. Keep the work area clean to prevent slips and falls. Check the machine for any defects before starting the machining process.

Why Aluminum is ideal for CNC machining?

Aluminum is ideal for CNC machining due to its excellent machinability, high strength-to-weight ratio, and corrosion resistance. Its low melting point allows for faster cutting speeds and reduced tool wear, resulting in quicker production times and cost savings. Additionally, aluminum's natural properties make it highly responsive to heat treatment, allowing for increased hardness and strength. Its non-magnetic and non-sparking characteristics also make it a safe choice for various applications. Overall, aluminum's versatility, durability, and ease of machining make it a preferred material for CNC machining processes.

Benefits of working with aluminum at TONZA

Working with Aluminum at TONZA offers a wide range of benefits for individuals and businesses alike. Aluminum is a lightweight and durable material, making it easy to transport and work with. It is also highly resistant to corrosion, ensuring longevity and low maintenance costs. Additionally, aluminum is a recyclable material, making it an environmentally friendly choice. At TONZA, our skilled professionals are experienced in working with aluminum, providing high-quality products and services. From custom designs to precision machining, working with aluminum at TONZA ensures efficiency, reliability, and cost-effectiveness. Trust us to meet your aluminum needs with excellence and expertise.

Why Choose ours Aluminum CNC machining services?

Each piece is manufactured to precise tolerances of ±0.01 mm, ensuring a flawless alignment to blueprint.

Tonza work with excellent raw material vendors to deliver excellent quality materials for your products.

Receive quick and exact DFM reviews to enhance your plan for fabrication and accelerate output.

With in-depth market knowledge, we provide reliable the substance CNC machining options.

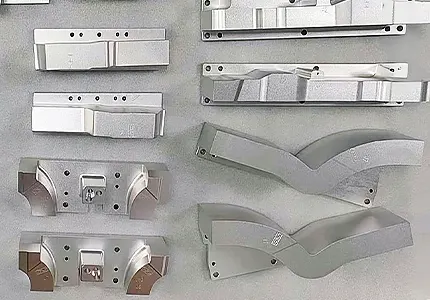

Capabilities of Aluminum CNC machining services

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

Tolerances

±0.05mm

Premium-grade tech solutions to provide you with crafted for superior durability.

Max part size

500 mm x 500 mm

Refined engineering excellence to provide you with engineered for excellence.

Min part size

5 mm x 5 mm

Comprehensive practical experience, know-how in producing complex parts.

Lead Time

< 10 days

Strong and structured management system, and fast and efficient production cycles

Surface Finish

Ra 0.8-1.6 µm

Streamlined group management, and maximized output.

Wall Thickness

0.75 mm

Years of practical expertise, equipped to tackle diverse and complicated projects.

Aluminum Material Properties

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in CNC machining.

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Fatigue Strength (MPa) | Elongation (%) | Hardness (HRC) | Density (g/cm³) | Typical Applications |

|---|---|---|---|---|---|---|---|

| 6061-T6 | ~310 | ~275 | ~96 | ~12 | ~22 | 2.70 | Aerospace parts, structural components, automotive |

| 7075-T6 | ~570 | ~505 | ~160 | ~11 | ~33 | 2.81 | Aircraft frames, high-strength applications |

| 2024-T3 | ~470 | ~325 | ~138 | ~10 | ~25 | 2.78 | Aerospace, military, transport |

| 5052-H32 | ~230 | ~193 | ~90 | ~12–18 | ~20 | 2.68 | Marine parts, fuel tanks, enclosures |

| 6082-T6 | ~340 | ~280 | ~95 | ~10 | ~24 | 2.70 | Bridges, cranes, transport structures |

| MIC-6 (Cast Plate) | ~152 | ~124 | ~55 | ~3 | ~17 | 2.66 | Jigs, fixtures, tooling plates (high dimensional stability) |

Notes:

- HRC (Hardness Rockwell C) values are approximate. Aluminum is usually measured with Brinell or Rockwell B scales, but HRC is shown for comparison.

- Fatigue Strength is typically given at 500 million cycles.

- Values vary slightly based on temper and manufacturing process.

Aluminum Machining Parameter

Our CNC equipment offer precision specifications that satisfy industry standards, ensuring uniform accuracy and seamless component alignment.

| Typical Value / Range | Notes | |

|---|---|---|

| Spindle Power | 3–30 kW | Higher power allows for more aggressive machining |

| Spindle Speed (RPM) | 6,000–24,000 RPM | Use high RPM for aluminum; 10,000–15,000 RPM is common |

| Feed Rate | 300–3,000 mm/min | Depends on tool size, flute count, and depth |

| Step Distance (Stepover) | 40–70% (roughing), 5–20% (finishing) of tool diameter | Smaller stepover improves surface finish |

| Cutting Depth (ap, ae) | Axial: 0.5–3 mm; Radial: 10–50% of tool diameter | Keep chip thickness consistent |

| Tool Path Strategy | Adaptive clearing (roughing), contouring (finishing) | Climb milling recommended |

| Coolant Type | Air blast, mist, MQL, flood | Air blast preferred to reduce aluminum chip sticking |

| Tool Material | Solid carbide (2–3 flutes), coated | Coatings like TiB₂ or ZrN help avoid built-up edge |

| Chip Removal Rate (MRR) | 50–500 cm³/min | MRR = Width × Depth × Feed Rate |

| Cutting Force | 50–500 N | Lower than steel; less tool wear |

| Surface Speed (Vc) | 300–900 m/min | Use to calculate optimal RPM: Vc = π × D × RPM / 1000 |

| Tool Coating | ZrN, TiB₂, DLC | Improves wear resistance, reduces aluminum sticking |

| Tool Wear Indicators | BUE, burrs, chatter | Regular inspection needed |

Surface Treatment of Aluminum

We furnish a wide range of CNC materials for bespoke parts, including cooper, brass, steel, plastics, aluminum, and over 100 other materials.

Brushing

Polishing

Tumbling

Anodizing

Black Oxide

Electroplating

Powder Coating

Alodine

Passivation

Electroless Plating

Application Industries of Aluminum

From automotive to aerospace, Tonza’s CNC machining meets the specific needs of diverse industries. We work with individual inventors, developers, and enterprise organizations, serving over 1,000 customers worldwide.

Choice Other Metal Materials Machining

Tonza’s CNC machines ensure high-standard precision tolerances for reliable accuracy and error-free component compatibility.

Brass CNC machining services

Cooper CNC Machining Service

Aluminum CNC Machining Service

Stainless Steel CNC Machining Services

Mild Steel CNC Machining Services

Magnesium CNC Machining Services

Titanium CNC Machining Services

Choice Other Plastics Materials Machining

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

ABS CNC machining services

PMMA CNC Machining Service

Nylon CNC Machining Service

PC CNC Machining Service

PP CNC Machining Services

PET CNC Machining Services

PEI CNC Machining Services

POM CNC Machining Services

PTFE CNC Machining Services

PEEK CNC Machining Services

HDPE CNC Machining Services

UHMW CNC Machining Services

FAQ about Aluminum machining

Here are some commonly asked questions and answers about our Aluminum CNC Machining Services.

We machine a wide range of aluminum alloys including 6061, 7075, 2024, 5052, and 6082, as well as specialized grades like MIC-6 and aluminum cast plates, based on mechanical and thermal requirements.

TONZA offers milling, turning, drilling, tapping, boring, and threading, using advanced 3-axis and multi-axis CNC machines for high-precision aluminum components.

Standard tolerances are ±0.05 mm, but we can achieve tighter tolerances down to ±0.01 mm depending on geometry, material condition, and specific customer requirements.

Yes, we provide Type II (decorative) and Type III (hardcoat) anodizing, available in a variety of colors and finishes to improve corrosion resistance, hardness, and aesthetics.

Absolutely. Our CNC equipment supports parts up to 1 meter in length and we specialize in complex geometries, pockets, and multi-surface features.

Yes, we support both rapid prototyping and low-to-mid volume production, with flexible capacity to scale as needed.

Lead times typically range from 3 to 10 business days, depending on part complexity, surface treatments, and volume. Rush orders can be expedited.

Yes. We can tap standard and custom threads (e.g., UNC, UNF, M-series) and install threaded inserts, helicoils, or press-fit components as specified.

We use optimized cutting strategies and sharp carbide tools, and apply deburring, edge breaking, and optional surface finishing to ensure smooth, burr-free results.

We offer anodizing, bead blasting, brushing, polishing, chromate conversion coating, powder coating, and clear or colored finishes to match aesthetic or functional needs.

Yes. Alloys like 7075-T6 and 2024-T3 offer excellent strength-to-weight ratios, making them ideal for aerospace, automotive, and performance-critical parts.

Definitely. Our engineers provide Design for Manufacturing (DFM) guidance to improve machinability, reduce costs, and ensure optimal performance of your aluminum parts.

CNC machining provides higher dimensional accuracy, better surface finish, and greater flexibility for low- to medium-volume production compared to casting or extrusion.

We serve a wide range of industries including aerospace, automotive, robotics, consumer electronics, medical devices, and industrial automation.

Upload your 3D CAD file (STEP, IGES, STL), specify alloy, quantity, and surface treatment, and our team will send you a detailed quote within 24 hours.