Expert 3D printing and rapid prototyping services..

Custom Online 3D printing service

Offer premium 3D printing services, delivering high-quality, precision-crafted parts with exceptional finishes at competitive prices.

- Tolerances: typically +/- 0.15mm or +/-0.006 inch

- Wide range of material choices

- Lead time as fast as 1 day

Types of 3D Printing

We provide comprehensive 3D printing services, utilizing various methods to accommodate diverse material needs and project specifications.

SLA

StereoLithography (SLA) is a high-resolution 3D printing technology that uses UV light to cure liquid resin layer by layer, producing precise, smooth, and detailed parts ideal for prototypes and complex designs.

SLS

Selective Laser Sintering (SLS) uses a laser to fuse plastic powder layer by layer, producing durable parts. It offers stronger material options, such as various grades of nylon, compared to SLA.

FDM

Fused Deposition Modeling (FDM) builds parts by layering melted thermoplastic filament. Unlike SLA and SLS, it accommodates larger parts and supports nearly all thermoplastics.

MJF

Jet Fusion (MJF) is an industrial 3D printing process that quickly produces strong, functional nylon parts with fine detail and quality finishes. Ideal for prototypes and end-use parts, it ensures consistent mechanical properties.

SLM

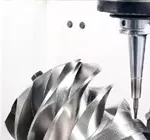

Selective Laser Melting (SLM) uses high-power lasers to fully melt metal powders, producing near-net-shape, high-density parts. Ideal for pure metals, it maintains mechanical properties through complete fusion.

Why Choose ours 3D Printing Service?

delivering exceptional results through experience, dedication, and strategic thinking.

working closely with clients to understand their unique needs and goals

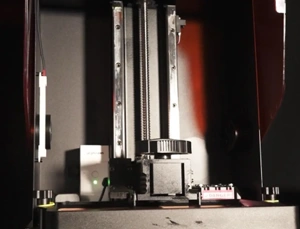

featuring the latest technology and advanced machinery to ensure precision, efficiency.

leveraging cutting-edge technology to manufacture intricate components

delivering exceptional value without compromising on quality or precision.

ensuring fast, efficient, and reliable production without compromising quality.

Capabilities of 3D Printing Services

Our 3D printing achieves precision tolerances that meet industry standards, ensuring accuracy and a perfect component fit.

| Name | SLA | SLS | MJF | FDM | SLM |

|---|---|---|---|---|---|

| Size | 800 × 1200 × 1700 mm | 500 × 500 × 600 mm | 380 × 284 × 380 mm | 500 × 500 × 600 mm | 500 × 500 × 600 mm |

| Material | White, Black, ellow, Transparent photosensitive resin | White, Black PA12, PA12+GF30%, PA12+Alu 40% | PA11,PA12,PA12+GB40% | PLA, PC, ABS, Nylon, ULTEM, Multi Colors | Stainless Steel, Ni-Cr, Co-Cr, AlSi10Mg, TC4, Tin Bronze |

| Cost | $ | $$ | $$ | $$ | $$$$$ |

| Standard Leading Time | 3-5 business days | 3-5 business days | 3-5 business days | 3-5 business days | 3-5 business days |

| Application | Appearance Prototypes | Function Prototypes | Function Prototypes | Appearance and Function Prototypes | Intricate Metal prototypes |

Design Guidelines

Enhance your designs for manufacturability with our expert guidance, ensuring optimal results in 3D printing.

SLS

2. Overhangs: No supports needed due to powder-based process.

3. Detail Resolution: Minimum 0.3 mm feature size.

4. Hollow Structures: Include escape holes (≥3 mm) to remove excess powder

SLA

2. Overhangs: Requires support structures.

3. Detail Resolution: Up to 0.1 mm for fine details.

4. Surface Finish: Smooth, ideal for high-detail prototypes.

MJF

2. Overhangs: No supports needed, like SLS.

3. Detail Resolution: Minimum 0.3 mm.

4. Strength & Functionality: Uniform mechanical properties throughout the part.

FDM

2. Overhangs: Requires supports beyond 45° angles.

3. Detail Resolution: 0.5 mm minimum feature size.

4. Layer Adhesion: Optimize orientation to strengthen load-bearing areas.

SLM

2. Overhangs: Supports needed beyond 45°.

3. Detail Resolution: 0.1–0.2 mm feature size.

4. Post-Processing: Heat treatment or machining often required.

Materials for 3D Printing

We provide a diverse selection of 3D printing materials, ensuring the ideal match for your specific application requirements.

Customers can confidently select the right materials and focus on product manufacturing.

Metal

Tipical: Stainless Steel-316L, Cobalt Chromium-CoCr, Aluminum alloy-AlSi10Mg and etc

Plastic

Tipical: Nylon (PA 11, PA 12, PA 6), TPU, PLA, ABS, and etc.

Post Processing

We are offering over 20 options of surface finishes to fulfill both your functional and aesthetic requirements.

As Processed

Polishing

Painting

Electroplating

Process Work

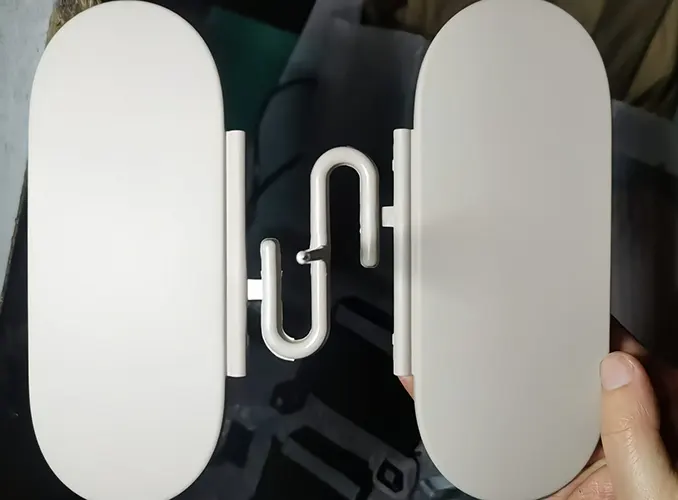

We provide top-quality Vacuum Casting services, delivering high-precision, finely finished parts at competitive prices.

01

Upload designed model

The most common file formats include STL, 3MF, PLY, FBX, STEP/IGES, and etc. Among these, STL is the most widely used for its simplicity, while 3MF and AMF offer advanced features like color, texture, and material properties.

02

Printing

We will proceed with arranging your order for 3D printing. Our team will ensure that your project meets the required specifications and is completed promptly. If you need any further assistance or adjustments, please feel free to let us know..

03

Post-processing

Post-processing improves the appearance and functionality of 3D prints, resulting in a smoother finish, richer colors, and increased durability.

Advantages

Ideal for prototyping, small production runs, and high-quality end-use components, our 3D printing solutions provide versatility and reliability for a wide range of applications.

Applications

Sheet metal fabrication produces a variety of parts and components, each tailored to meet specific functional and aesthetic requirements.

Automotive

- Prototypes for vehicle components – Rapid design testing for parts like bumpers, dashboards, and engine components.

- Custom parts and modifications – Unique or low-volume parts for classic cars and performance upgrades.

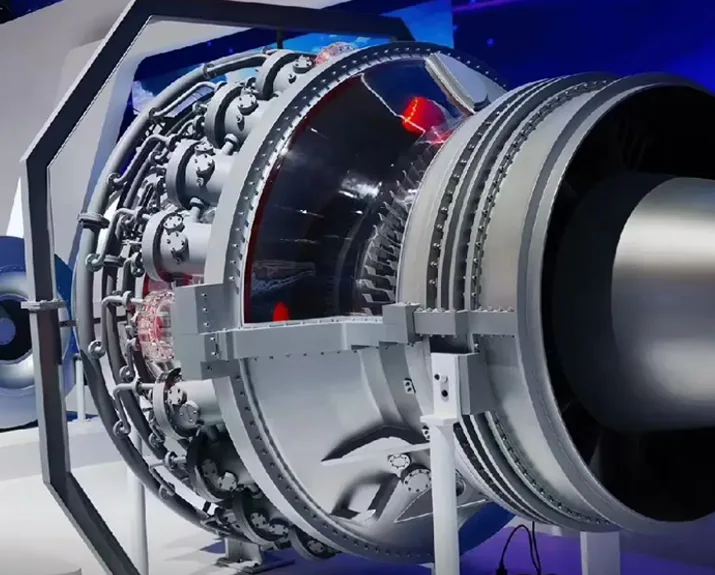

Aerospace

- Complex engine components – Turbine blades, fuel nozzles, and heat exchangers with optimized geometries.

- Satellite and UAV components – High-precision, durable parts for space and unmanned systems.

Electronic

- Custom enclosures and housings – Tailored casings for consumer electronics and industrial applications.

- Wearable devices – 3D-printed smartwatches, fitness trackers, and AR/VR equipment components.

- Cooling solutions – Custom heat sinks and airflow-optimized designs.

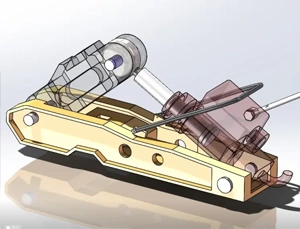

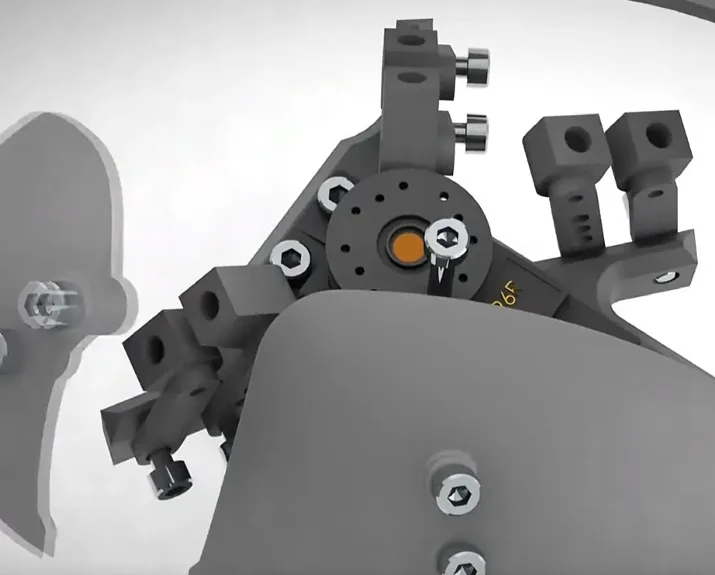

Industrial Machinery

- Gears and mechanical assemblies – Functional prototypes and production-ready machine components.

- Automation and robotics – Custom brackets, mounts, and structural elements for automation systems.

Medical

- Prosthetics and orthotics – Custom-fitted artificial limbs and supportive devices.

- Anatomical models – Patient-specific models for surgical planning and medical education.

- Medical device prototypes – Rapid testing and development of new medical equipment.

Military and Defense

- Customized weapon components – Firearm grips, sights, and modular accessories.

- Field repair and replacement parts – On-site printing of mission-critical components.

- Unmanned systems (UAVs and robots) – Lightweight structures for drones and robotic systems

FAQ

We provide SPI surface finishes for injection-molded parts. Our experts are ready to help you select the ideal finish for your project.

We provide SLA, SLS, MJF, FDM, SLM, and WAAM 3D printing services to meet various industrial and prototyping needs.

We offer a wide range of materials, including plastics (ABS, PLA, Nylon, TPU, Resin), metals (Aluminum, Stainless Steel, Titanium, Copper), and composite materials.

Production time depends on the complexity and size of the part, but we typically deliver within 1 to 7 days.

Yes, we provide worldwide shipping with reliable logistics partners to ensure safe and fast delivery.

We accept STL, STEP, IGES, and OBJ files. If you need assistance with file preparation, our engineers can help.

Yes, we support both customized single-piece orders and mass production, ensuring high quality and consistency.

We serve various industries, including automotive, aerospace, healthcare, electronics, consumer goods, and manufacturing.

Yes, we offer sanding, polishing, painting, plating, and heat treatment for enhanced surface finish and durability.

Simply send us your 3D file and specifications, and we’ll provide a detailed quote within 24 hours.

We provide high-quality prints, competitive pricing, fast turnaround, advanced technologies, and excellent customer support to meet your project requirements.

Blog

Welcome to our blog, where we share insights into various manufacturing processes.