Titanium alloys are a material that is highly sought after in industrial applications yet poses significant challenges in machining workshops.

With low density, high specific strength, and exceptional corrosion resistance, they find extensive use in high-end sectors such as aerospace, biomedical engineering, and automotive manufacturing.

However, these very advantages make titanium alloys notoriously difficult to machine.

During milling operations, one of titanium alloys’ most prominent characteristics is their poor thermal conductivity.

Heat generated during cutting struggles to dissipate rapidly into the workpiece, instead concentrating in the cutting zone where the tool contacts the material.

This causes cutting temperatures to surge, subjecting the tool edge to prolonged high temperatures and accelerating wear.

Simultaneously, titanium alloys exhibit heightened chemical reactivity at elevated temperatures, readily interacting with tool materials to form hardened layers at the contact interface.

These layers not only increase cutting forces but also further shorten tool life.

In practical production, while diamond tools are widely regarded as the most effective cutting tools for machining titanium alloys, their high cost limits their application scope.

Consequently, carbide end mills remain the mainstream choice for machining titanium alloys such as TC4.

The key research focus lies in optimizing tool structure, surface coatings, and cutting parameters to enable carbide end mills to achieve “less wear and higher productivity” during titanium alloy machining.

Tool Structure: Creating Clear Pathways for Chip and Heat Removal

During titanium alloy milling, the smooth evacuation of chips significantly impacts process stability.

Chip accumulation in the cutting zone not only impedes continued machining but also elevates local temperatures, accelerating tool wear.

Consequently, optimizing chip evacuation channels in tool design is crucial.

Research indicates that employing a large V-shaped chip-holding groove structure effectively increases chip evacuation space, facilitating easier removal of chips from the cutting zone.

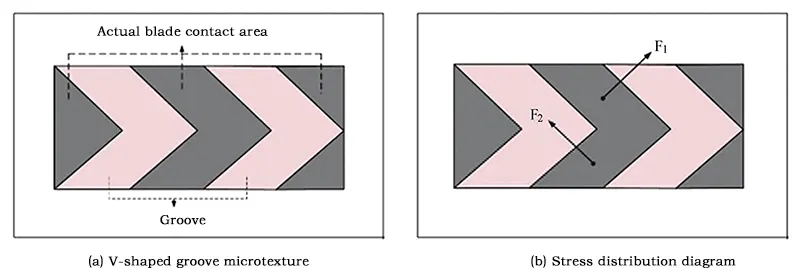

This reduces localized temperatures and extends tool life. Building upon this, scholars have applied biomimetic principles to design V-shaped groove microtextures on the surface of ball-nose end mills.

Through systematic analysis of how microtextures influence cutting forces and heat generation during titanium alloy milling, the effects of key microtexture parameters were clarified.

Optimal comprehensive tool performance was achieved with a groove opening angle of 79°, a spacing of 170 μm, a width of 30 μm, and a distance of 90 μm from the cutting edge.

Experimental results demonstrate that this optimized microtexture significantly reduces milling forces and improves workpiece surface roughness.

In addition, it effectively mitigates tool wear, providing a viable technical pathway for efficient and high-quality titanium alloy machining.

Beyond microtexture design, the chipbreaker groove structure of solid end mills also warrants attention.

Through simulation and experimental validation of chipbreaker geometry, researchers discovered that a well-designed chipbreaker facilitates chip breaking and evacuation.

It also improves the tool’s stress state, resulting in smoother cutting processes that enhance efficiency and extend tool life.

Edge Geometry: Transforming “Hard Impact” into “Gradual Feed”

The shape of the tool edge directly determines how cutting forces act upon the tool and workpiece.

Traditional ball-nose end mills tend to generate localized high cutting force concentrations when machining titanium alloys.

In contrast, arc-shaped end mills, by designing the cutting edge as an arc, can distribute cutting forces during machining, thereby reducing stress concentration levels.

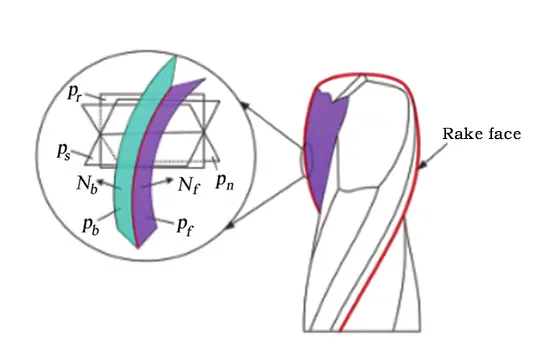

Researchers designed a novel arc-shaped end mill with a high-curvature cutting edge.

Using differential geometry methods, they established mathematical models for the tool contour surface and helical cutting edge to achieve precise control over the grinding process.

Experimental results demonstrate that during side milling, the arc milling cutter significantly reduces the primary cutting force, exhibits greater process stability, and shows markedly slower wear rates compared to ball-nose cutters.

Further testing indicates that even as the milling length increases, workpiece surfaces machined by the arc cutter maintain low roughness and flatness without noticeable defects.

Related research also found that under identical machining conditions, the main cutting force of arc-shaped milling cutters was approximately 30% lower than that of ball-nose cutters, with smaller fluctuations in cutting force.

Regarding wear patterns, arc-shaped cutters primarily exhibited adhesive wear, whereas ball-nose cutters also experienced oxidation wear and diffusion wear, resulting in shorter tool life.

These results indicate that in TC4 titanium alloy machining, arc-shaped milling cutters offer distinct advantages in cutting stability, machining quality, and tool life.

Tool Angles: Subtle Yet Critical to Performance

When machining titanium alloys, geometric parameters such as the tool’s rake angle, clearance angle, helix angle, and edge inclination often amplify cutting performance.

An appropriate rake angle reduces cutting forces and improves heat dissipation, while the clearance angle minimizes friction between the tool and workpiece surface.

The helix angle and edge inclination help stabilize the cutting process and control chip flow direction.

Research on microtextured ball-nose end mills machining titanium alloy curved surfaces revealed that the tool inclination angle most significantly affects milling force.

Meanwhile, the microtexture diameter is the key factor influencing cutting temperature and surface roughness.

By establishing a cutting performance evaluation model and combining it with artificial fish swarm algorithm for parameter optimization, the optimal parameters obtained were:

- tool inclination angle 25°

- microtexture diameter 70 μm

- microtexture spacing 125 μm

- distance from cutting edge 90 μm.

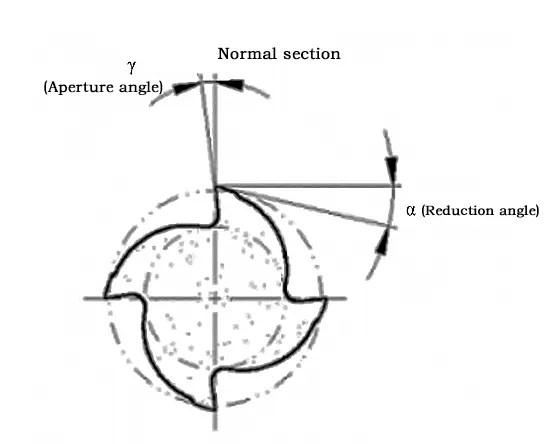

Furthermore, research on optimizing end mills for aerospace titanium alloys from three aspects—tool material, geometry, and surface coating—indicates that using fine-grain cemented carbide as the tool material can significantly enhance performance.

Selecting a front angle γ between 10° and 15°, a rear angle α around 10°, and a helix angle β between 30° and 40°, combined with an appropriate surface coating, can further improve tool wear resistance and machining efficiency.

Tool Passivation: Not “Dulling,” But “Enhancing Durability”

In titanium alloy machining, the material’s high chemical reactivity causes tool edges to undergo reactive wear.

Edge passivation treatment forms a more stable geometric profile and surface condition at the cutting edge, thereby reducing chemical reactions between the tool and titanium alloy.

The study compared the cutting performance of three tool types: unpassivated, vertically rotary passivated, and rotary abrasive flow passivated.

Results showed that compared to unpassivated tools, vertical rotary passivation reduced cutting force by 27.01% and cutting temperature by 11.21%.

Rotary abrasive flow passivation demonstrated even more pronounced effects, lowering cutting force and cutting temperature by 35.67% and 22.88%, respectively.

Further analysis indicates that rotary abrasive flow passivation not only reduces cutting forces more effectively but also improves edge consistency and surface finish quality.

Therefore, it is more suitable for practical application in TC4 titanium alloy milling.

Coating Technology: Equipping Tools with a “Protective Suit”

To address the tendency of titanium alloys to chemically react with tools at elevated temperatures, cemented carbide milling cutters typically require surface coating treatment.

Coatings significantly enhance tool surface hardness, wear resistance, and thermal stability while reducing friction coefficients and minimizing adhesion and built-up edge formation.

Research indicates that among various coating systems, NbN/TiAlN composite coatings exhibit outstanding friction and wear properties at both room and elevated temperatures.

After magnetic field treatment, the tool life of coated cutters increased from 21 minutes to 36 minutes.

When cutting speed increased to 120 m/min, the life of the coating-treated inserts extended from 12 min to 30 min after light cryogenic treatment.

Another novel CrSiCN coating also demonstrated outstanding performance, achieving a microhardness of 3049 HV0.01 and a film-substrate bond strength of 94 N.

During high-speed milling of TC4 titanium alloy, the coated tool demonstrated a 144% longer service life compared to uncoated carbide tools and a 50% increase over GT-1 composite coatings.

This improvement primarily stems from the coating’s effective suppression of titanium alloy welding behavior and reduction of cutting zone temperatures.

Regarding nano-coatings, milling cutters with TiAlSiN nano-composite coatings significantly reduce cutting forces and temperatures under identical machining conditions.

They also deliver superior surface quality, making them particularly suitable for machining thin-walled titanium alloy components.

Cutting Parameters: Balancing Efficiency and Tool Life

Given titanium alloys’ high hardness and poor thermal conductivity, selecting optimal cutting parameters critically impacts machining outcomes.

Research indicates that among various cutting parameters, the depth of cut (ap) most significantly affects cutting forces. As ap increases, the cutting forces on the tool teeth rise markedly.

Under medium-to-high-speed milling conditions, appropriately reducing ap while increasing feed rate can effectively lower cutting forces while maintaining machining efficiency, thereby extending tool life.

In contrast, cutting speed has a relatively minor impact on cutting forces.

Research on TC11 titanium alloy employed a combined finite element simulation and experimental approach to determine optimized tool geometry parameters: front angle γ = 8.0116°, rear angle α = 10.0501°, and helix angle β = 44.9629°.

Under identical machining length conditions, the optimized tool exhibited significantly reduced rake face wear and markedly extended tool life.

When combined with liquid nitrogen cryogenic cooling, tool life can be further extended by approximately 20%.

Conclusion

Overall, while titanium alloys present machining challenges, they are far from “unsolvable.”

Through systematic optimization of the carbide milling cutter’s structural design, cutting edge geometry, dulling methods, coating systems, and cutting parameters, it is possible to effectively reduce cutting forces and temperatures.

This approach also extends tool life and significantly enhances machining quality.

These studies provide a solid theoretical foundation and engineering reference for the efficient and stable machining of titanium alloy components in fields such as aerospace and biomedical engineering.

FAQ

Impedit egestas aliquet?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Sapien class quo temporibus?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Elementum voluptate sodales?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.