Workholding fixtures serve as critical auxiliary tools in the machining process of CNC milling machines. Their design rationality directly impacts workpiece machining accuracy, production efficiency, and manufacturing costs.

Although CNC milling machines are vital application equipment for CNC technology, characterized by high precision, efficiency, flexibility, and broad adaptability, they cannot fully realize their potential without well-designed workholding fixtures.

Therefore, the design and improvement of workholding fixtures are particularly crucial.

Researching methods for designing and enhancing CNC milling machine workholding fixtures holds significant importance for boosting the machining capabilities and market competitiveness of CNC milling machines.

Overview of CNC Milling Machine Workholding Fixtures

Since the emergence of the mechanical manufacturing industry, workholding fixtures have advanced alongside the sector’s development, evolving from early simple positioning systems to today’s complex systems.

Role of Fixtures in CNC Milling Machines

Fixtures play a vital role in CNC milling machines. They not only ensure high efficiency and precision during machining but also decisively enhance product quality and production flexibility.

To illustrate with a specific example, in automotive component production, a meticulously designed fixture can control part positioning errors within 0.01 millimeters, significantly enhancing machining precision.

Classification and Characteristics of Fixtures

As a critical auxiliary tool in CNC milling operations, the classification and characteristics of fixtures directly impact machining efficiency and product quality.

Based on processing requirements, fixtures can be categorized into universal fixtures, specialized fixtures, and modular fixtures.

Universal fixtures, such as three-jaw self-centering chucks, enable rapid clamping for diverse components but often fall short in precision and efficiency compared to specialized fixtures.

Special-purpose fixtures are designed for specific parts, significantly enhancing machining accuracy and production efficiency.

For instance, in the automotive industry, specialized fixtures enable precise positioning and secure clamping of engine cylinder blocks, ensuring machining accuracy.

Modular fixtures offer greater flexibility through modular design, allowing rapid adaptation to different part machining requirements.

Key Design Considerations for CNC Milling Fixtures

The design of CNC milling machine fixtures should prioritize accurate positioning, reliable clamping, and convenient setup, while also considering structural rigidity, efficient chip removal, and operational safety.

While ensuring machining accuracy and efficiency, fixtures should offer good versatility and adjustability.

They should accommodate the machining requirements of different workpieces while facilitating quick setup, removal, and maintenance, thereby enabling efficient and stable CNC machining.

Design Principles for Locating References

In CNC milling operations, fixture design is critical to ensuring machining accuracy and efficiency. Among these, the design of locating references is particularly vital, as it directly determines the installation precision and stability of the workpiece.

Adhering to the six-point locating principle (3-2-1 rule) forms the foundation for achieving precise machining.

(1) Primary Reference Surface:

Employ planar contact to restrict three degrees of freedom. The primary reference surface is typically selected as a large, relatively flat surface on the workpiece.

This planar contact method effectively limits the workpiece’s three translational degrees of freedom (X, Y, Z directions).

For example, when machining large plate-like components, the workpiece is placed on a flat workbench. Contact between the workbench surface and the workpiece fixes its position.

This method is not only simple to operate but also provides high stability, laying a solid foundation for subsequent machining.

(2) Side Reference Surface:

Line contact restricts two degrees of freedom. The side reference surface further constrains the workpiece’s two rotational degrees of freedom (around the X-axis and Y-axis) through line contact.

For instance, when machining parts with side features, V-blocks or inclined fixtures can be set up to create line contact between the workpiece’s side and the fixture.

This approach ensures machining accuracy while reducing pressure on the workpiece surface, preventing deformation caused by excessive clamping.

(3) End Reference Surface:

Point contact restricts one degree of freedom. The end reference surface limits the final rotational degree of freedom (around the Z-axis) through point contact.

This design is typically used for precise angular or directional positioning of the workpiece. For instance, when machining certain high-precision aerospace structural components, pins or other locating elements are used to mate with holes in the workpiece, forming point contact to complete the final positioning process.

Dynamic Clamping Force Balancing Design

In industrial production, precise control of clamping force is critical for ensuring machining accuracy and efficiency. Hydraulic system design must consider multiple factors to achieve dynamic equilibrium.

The core of dynamic clamping force balancing design lies in utilizing scientific calculations and real-time monitoring technologies to guarantee stable and efficient clamping force throughout the machining process.

![]()

Among these, (F) represents the effective clamping force, a key indicator of the entire system’s performance; (P) denotes hydraulic pressure, which determines the system’s driving force; (A) signifies the piston area, directly affecting force transmission efficiency; (\mu) indicates the friction coefficient, reflecting the friction characteristics between materials; while (K_s) is the safety factor, used to account for uncertainties in actual operation.

Precise calculation and adjustment of these parameters ensure the clamping force theoretically achieves an optimal state.

Material and Structural Optimization

(1) Locating Pins:

T8 tool steel → Tungsten carbide coating. Traditional locating pins made from T8 tool steel exhibit limited strength and wear resistance. Under high-stress conditions, their service life is insufficient.

Engineers proposed a new solution: applying a tungsten carbide coating to the locating pin surface. This coating offers high hardness, resistance to wear and corrosion, significantly extending service life. Tests show the coated pins last three times longer than traditional T8 tool steel pins.

This technology further reduces maintenance costs, boosts production efficiency, and achieves a win-win outcome for both technical performance and economic benefits.

(2) Clamping Body:

HT200 Cast Iron → 7075 Aluminum Alloy + Topology Optimization. Optimizing the clamping body highlights the importance of integrating material selection with structural design.

While HT200 cast iron clamping bodies are robust, their heavy weight limits lightweight applications. The R&D team explored replacing them with 7075 aluminum alloy, renowned for its high strength-to-weight ratio and commonly used in aerospace.

However, material substitution alone was insufficient. The team further incorporated topology optimization technology.

Through computer simulation analysis, the internal structure of the clamping body was redesigned to eliminate redundant sections while preserving critical load-bearing zones.

Fixture Improvement Strategy

Improvements to CNC milling machine fixtures should focus on structural optimization and functional upgrades. Adopting modular design, rapid positioning, and clamping systems enhances mounting efficiency and precision.

Simultaneously, integrating CNC simulation and finite element analysis optimizes stress distribution and deformation, enhancing fixture rigidity and stability.

Incorporating intelligent monitoring and automated adjustment technologies enables real-time monitoring and adaptive regulation of fixture conditions, thereby comprehensively improving machining precision, efficiency, and reliability.

Core Components of Modular Rapid Changeover Systems

First, standard interface base plates (ISO/BT specifications).

Serving as the foundation of the entire modular system, these base plates are designed to internationally recognized ISO or BT standards, ensuring seamless integration between different equipment.

This standardization not only reduces procurement costs but also significantly enhances equipment compatibility, enabling enterprises to rapidly adjust production lines when facing diverse manufacturing tasks.

Second, the Adjustable Positioning Module Library.

This library is a critical component of the modular system. Comprising a series of pre-calibrated positioning elements, it allows flexible combinations tailored to specific machining requirements, achieving precise workpiece positioning.

Compared to traditional fixed fixtures, this modular design significantly enhances adaptability and operational convenience.

Third, Pneumatic Quick-Change Device (Changeover Time < 3 min).

The pneumatic quick-change device serves as the “speed champion” within the modular system. Utilizing compressed air drive principles, this device completes fixture replacement and locking in minimal time, reducing the previously time-consuming manual adjustment process to under 3 minutes.

Intelligent Upgrade Pathways

(1) IoT Integration:

Integrating RFID chips enables comprehensive fixture lifecycle management. As smart manufacturing advances, the demand for refined equipment management grows increasingly critical.

By embedding RFID (Radio Frequency Identification) chips into fixtures, precise tracking and management across their entire lifecycle become achievable.

This technology not only records real-time usage status, maintenance history, and retirement cycles but also leverages big data analytics to predict potential failures, effectively reducing production downtime risks.

For instance, in a real-world application at an automotive manufacturing plant, the introduction of RFID technology extended the average service life of fixtures by 15% while reducing maintenance costs by 20%.

This demonstrates the immense potential of IoT technology in enhancing production efficiency and lowering costs.

(2) Adaptive Compensation:

A thermal deformation compensation system based on laser displacement sensors. In precision machining, thermal deformation has long been a critical factor affecting product quality.

To address this challenge, an adaptive compensation system based on laser displacement sensors was developed.

The core principle of this system utilizes the thermal expansion formula: ΔL = LαΔT, where L represents the original length of the object, α is the material’s thermal expansion coefficient, and ΔT is the temperature change.

Real-time monitoring of thermal deformation in workpieces and fixtures is achieved via laser displacement sensors, with data transmitted to the control system.

The control system automatically adjusts machining parameters—such as tool paths and cutting depths—based on thermal expansion formulas, enabling precise compensation for thermal deformation.

Safety Protection Enhancements

Safety remains the paramount consideration in modern industrial production. Technicians comprehensively optimized critical processes by developing a dual-loop clamping confirmation system.

This system employs a dual-detection mechanism to ensure the fixture’s operational status aligns with expectations, effectively preventing “false clamping” incidents. This enhances operational safety and reduces economic losses.

For chip deflection, technicians innovatively redesigned the fixture body structure, incorporating a 30° inclined chip evacuation groove.

This guides cutting debris for smooth removal, minimizes clogging risks, and protects workpiece surfaces from damage.

Application Validation and Benefit Analysis

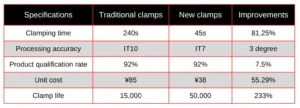

Taking the machining of a ϕ200mm impeller at a mold manufacturer as an example, replacing the traditional fixture with the improved version not only significantly enhanced machining accuracy but also substantially reduced production costs and time consumption. The following presents specific data comparisons and in-depth analysis.

Comparative Analysis of Fixture Improvement Solutions

First, analysis of pain points in the original solution: The traditional three-jaw chuck fixture relied on a single reference surface for positioning, presenting the following issues:

① Repeat positioning accuracy limited to ±0.05mm, causing 0.1mm deviation in coaxiality between impeller shaft bore and blade profile;

② Manual clamping requiring 3–5 minutes per part, high labor intensity necessitating three fixture sizes for different product batches, with annual maintenance costs exceeding ¥120,000;

③ Blade deformation rate as high as 8% (primarily in thin-walled areas).

Second, Technical Breakthroughs in the Improvement Plan Innovative design of a new modular hydraulic fixture.

① Three-stage step positioning system:

Features adaptive positioning rings at 180/200/220mm, accommodating workpieces with ±0.5mm tolerances;

② Hydraulic compensation mechanism:

8 evenly distributed hydraulic pins with adjustable pressure (5–20MPa), controlling thin-wall deformation within 0.02mm;

③ Intelligent sensing system:

Integrated pressure/displacement sensors for real-time monitoring of clamping status;

④ Quick-change module design:

Reduces impeller positioning module replacement time to 30 seconds[5]. Third, Comparison of Improvement Effects:

Improvement effects are compared as shown in Table 1.

Clamping Fixture Structural Diagram Explanation

Core Component Analysis:

① Three-stage positioning ring. Manufactured from quenched 42CrMo steel with hard chrome plating, achieving positioning accuracy of ±0.005mm¹¹;

② Hydraulic compensation unit. Each ejector unit incorporates pressure sensors and displacement feedback devices;

③ Quick-change interface. ISO-standard HSK63 interface enabling module switching within 10 seconds;

④ Intelligent monitoring module. Integrates Siemens S7-1200 PLC for digital management of clamping parameters. Details shown in Figure 1.

Conclusion

In summary, this exploration of CNC milling machine tooling fixture design and improvement has achieved significant results. Through enhancements in the modular quick-change system, intelligent upgrades, and safety protections, the project not only improved clamping accuracy and substantially reduced single-piece processing time but also effectively controlled tool wear costs.

The implementation of these improvement strategies has not only boosted production efficiency and lowered production costs but also enhanced the applicability and flexibility of the tooling fixture, bringing revolutionary changes to the machining process of CNC milling machines.

FAQ

What is a CNC milling machine workholding fixture, and why is it important?

A CNC milling machine workholding fixture is a device that securely holds and positions a workpiece during machining. It ensures precision, stability, and repeatability. Well-designed fixtures directly influence machining accuracy, efficiency, and manufacturing costs, making them essential for high-quality CNC operations.

How do fixtures improve machining accuracy and efficiency in CNC milling?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinaFixtures enhance machining accuracy by maintaining consistent positioning and alignment, often achieving precision within 0.01 mm. They also improve efficiency through faster clamping, reduced setup times, and stable cutting conditions—especially vital in high-precision industries like automotive and aerospace manufacturing.r dapibus leo.

What are the main types of CNC milling fixtures?

CNC milling fixtures are typically divided into universal, specialized, and modular types.

Universal fixtures suit diverse components but sacrifice precision.

Specialized fixtures are custom-built for specific parts, maximizing accuracy.

Modular fixtures combine flexibility and precision, adapting quickly to various machining tasks.

What are the key design principles for CNC fixture locating references?

Designers follow the six-point locating principle (3-2-1 rule):

Primary surface: planar contact limits three degrees of freedom.

Side surface: line contact limits two rotational freedoms.

End surface: point contact limits the final degree of freedom.

This method ensures accurate, stable positioning during CNC machining.

How can clamping force balance improve CNC machining performance?

Dynamic clamping force balancing maintains consistent pressure during machining. By optimizing hydraulic parameters—such as pressure, piston area, and friction coefficients—engineers achieve stable clamping. This reduces vibration, improves surface quality, and extends both tool and fixture life.

What materials and structural optimizations enhance fixture performance?

Upgrading materials (e.g., T8 tool steel → tungsten-carbide-coated pins or HT200 cast iron → 7075 aluminum alloy) greatly improves wear resistance and reduces weight. Combined with topology optimization, such upgrades boost rigidity, reduce deformation, and increase fixture lifespan by up to three times.

How do modular rapid-change systems improve fixture efficiency?

Modular quick-change systems use standardized base plates, adjustable positioning modules, and pneumatic clamping units. They enable fixture changes in under 3 minutes, minimizing downtime and allowing rapid adaptation for different workpieces, thereby increasing CNC productivity and versatility.

How does IoT integration enhance fixture management in smart manufacturing?

Embedding RFID chips in fixtures allows real-time tracking of usage, maintenance, and lifecycle data. This smart monitoring, combined with big-data analytics, predicts failures, reduces downtime, and can extend fixture service life by 15 % while lowering maintenance costs by 20 %.

How does adaptive thermal deformation compensation improve machining precision?

Using laser displacement sensors, the system monitors temperature-induced deformation in real time. The control software then adjusts tool paths and cutting depths automatically, compensating for thermal expansion and ensuring consistent precision during long-duration or high-temperature machining.

What benefits can be achieved by improving CNC milling fixtures?

Enhanced CNC fixtures deliver higher precision, shorter setup times, reduced tool wear, and lower maintenance costs. Case studies show productivity gains exceeding 30 %, clamping accuracy within ±0.005 mm, and processing time per part cut by more than half—transforming efficiency and competitiveness.