Thin-wall turning is a precision machining process used to produce components with very thin outer walls relative to their diameter or overall size.

Industries such as aerospace, medical, and electronics commonly use this technique to produce lightweight, high-precision parts.

Unlike conventional turning, thin-wall turning presents unique challenges due to the reduced rigidity of the workpiece. Thin walls are prone to deformation, vibration, and chatter during machining, which can affect dimensional accuracy and surface finish.

Therefore, it requires optimized cutting parameters, sharp tools, stable fixturing, and careful control of cutting forces.

Advanced CNC lathes, especially those with high-speed spindles and dynamic control, are often used for thin-wall turning.

The process may also employ techniques such as step-by-step roughing and finishing, constant tool pressure strategies, and the use of specialized tool geometries to ensure minimal distortion.

Using two thin-walled ring components made of GH4169 nickel-based high-temperature alloy as case studies, this research investigates deformation control strategies.

The results show that using fixtures to support the ring’s inner cavity and adding filler materials to reinforce it enhances machining rigidity.

This approach effectively mitigates turning deformation in thin-walled parts, demonstrating broad applicability and significant results.

Introduction

Nickel-based superalloys, exemplified by GH4169, typically exhibit a hardness of 346–450 HBW. This material is an ideal manufacturing choice for aerospace engines due to its high thermal strength, excellent mechanical properties, and corrosion resistance.

However, as a typical difficult-to-machine material, it generates high cutting forces, elevated cutting temperatures, severe tool wear, significant work hardening, and pronounced tool sticking during machining.

Its material characteristics dictate that severe deformation occurs under both mechanical stress and thermal effects during machining.

Thin-walled ring components offer advantages such as lightweight construction, high thrust-to-weight ratio, material savings, and compact design, making them widely adopted in aviation engine applications.

In aerospace manufacturing, thin-walled ring components are primarily produced through turning processes, typically achieving material removal rates exceeding 90%.

These components are highly susceptible to deformation during machining, leading to dimensional deviations.

Thin-walled nickel-based high-temperature alloy rings combine the challenges of both difficult machinability and thin-walled construction.

Therefore, appropriate measures must be taken to reduce deformation during machining. Effectively supporting or filling the thin-walled sections is one of the most common and effective methods.

For high-temperature alloy thin-walled rings of different sizes and structures, different support or filling methods should be selected based on their shape, size, and process plan.

This paper presents two thin-walled rings of differing sizes and structures as case studies, demonstrating three practical methods employed to mitigate turning deformation.

Fixture-Assisted Support

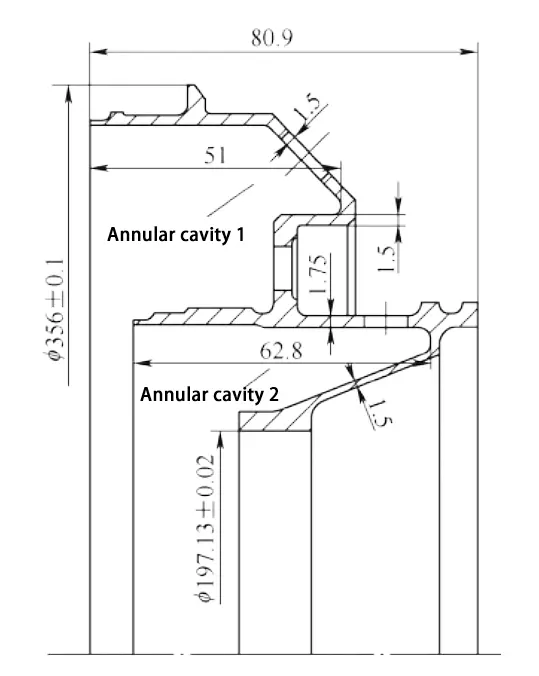

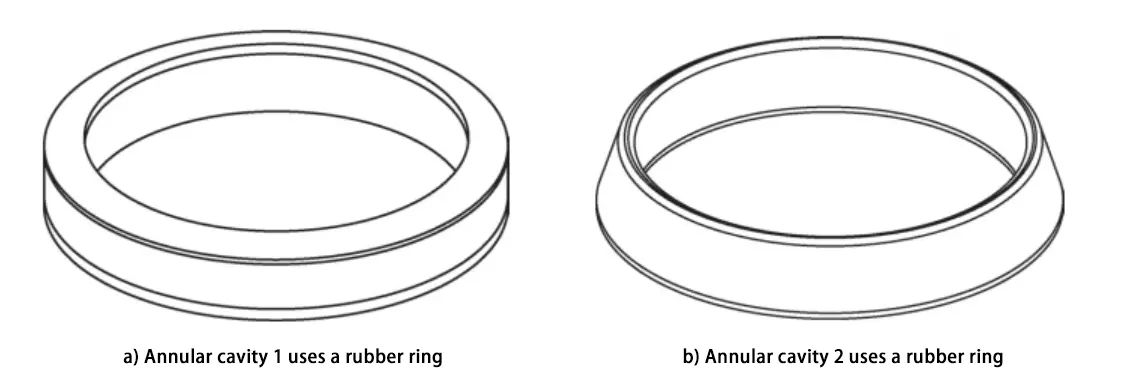

Case Study 1 (Figure 1) features a conical sealing ring made of GH4169 nickel-based high-temperature alloy for aerospace engine applications.

The cross-section reveals a maximum diameter of 356.1 mm, a minimum diameter of 197.11 mm, and a total length of 80.9 mm.

Its configuration features two annular cavities with depths of 51 mm and 62.8 mm, respectively, and peripheral wall thicknesses ranging from 1.5 to 2.5 mm, making it a typical thin-walled ring component.

Process Arrangement

The basic turning approach involves two roughing passes to remove most stock, heat treatment to relieve roughing stresses, and reference surface correction to address distortion from heat treatment.

Two semi-finishing passes further remove material while retaining a 1mm allowance, followed by two finishing passes to achieve the final shape.

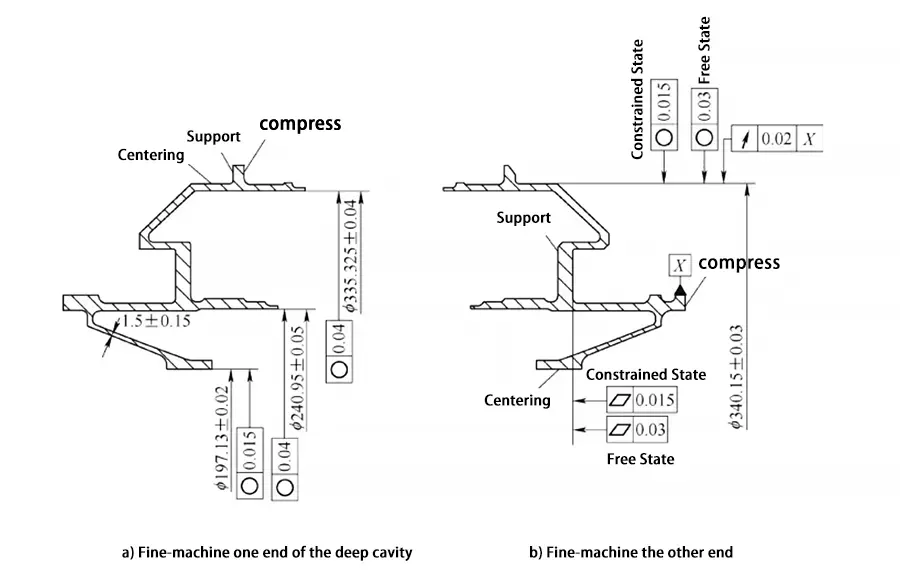

Regardless of the process sequence, the final finishing operation inevitably requires turning one end, followed by flipping the workpiece to turn the other end.

To minimize deformation, it is preferable to first finish-turn the end with two annular cavities, then finish-turn the other end, as shown in Figure 2.

Need for Auxiliary Support

Conventional clamping methods cause deformation due to tool pressure, resulting in machining failure. Repeated tool passes on the material’s inherent properties only induce surface hardening or even overcutting.

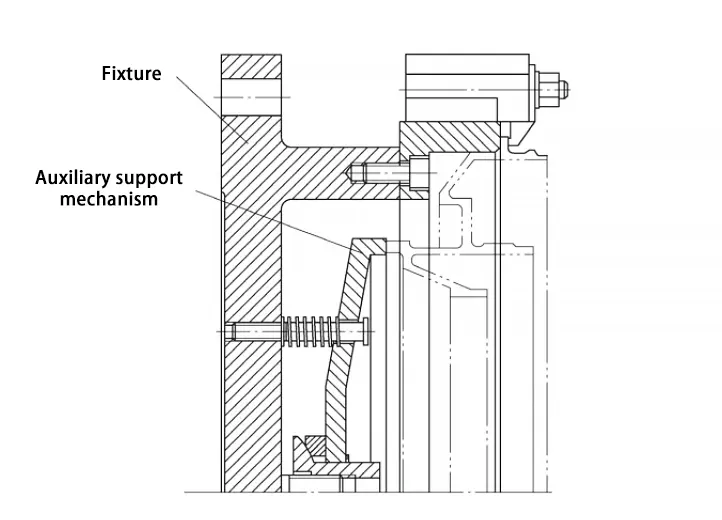

Therefore, employing a floating auxiliary support to enhance rigidity during deep cavity end finishing alleviates machining deformation.

The basic structure of the auxiliary support is shown in Figure 3, consisting of a spring ring and a locking nut.

During use, simply keep the locking nut loose, mount the part on the fixture, and adjust the locking nut while using a dial indicator to secure the auxiliary support against the part.

Compared to rigid supports, this approach avoids over-constraint interference from machining errors while preventing loss of support function due to clearance.

Drawbacks include relatively complex part structure, high dimensional accuracy requirements, manufacturing difficulty, and inconvenient operation—each use necessitates dial gauge adjustment to ensure uniform force distribution.

Molded Rubber Filler Support

Case Study: During finish turning of the opposite end of this part, two annular cavities similarly compromised structural rigidity. Conventional machining caused deformation due to tool compression and severe tool chatter, rendering the operation unfeasible.

Since machining this end involves the outer periphery of the annular cavity, research indicated that filling the cavity to enhance rigidity would more directly improve stiffness and resolve tool chatter than constructing auxiliary supports.

This approach employs a rubber-made annular support filler. The fabrication method is as follows:

1) Select rubber material with the following properties: operating temperature range of -30 to 120°C, Shore hardness of 30 to 60 HS, elastic modulus G of 525 to 1260 N/m², compression set under static load <15%, and compression set under dynamic load <5%.

2) Determine the dimensions of the vibration-damping rubber ring (see Figure 4) based on the cavity dimensions on the opposite side of the machined part.

Due to rubber’s high elasticity, the rubber ring and part should have an interference fit; thus, the rubber ring dimensions should be 1–2 mm larger than the cavity dimensions.

Then, machine the vibration-damping rubber ring according to the determined dimensions. Machining methods may include turning or heating the rubber to a molten state for mold casting.

3) Insert the rubber ring into the part cavity during machining. If the filling is unstable, secure the rubber ring to the fixture using bolts or adhesive before clamping the part for machining. The filling support for annular cavities is shown in Figure 5.

Verification confirms this method effectively enhances the rigidity of hollow parts, significantly reduces elastic deformation caused by cutting forces, and provides excellent vibration absorption from the rubber, thereby minimizing machining vibrations.

Additionally, this approach is relatively easier to implement compared to fabricating auxiliary supports.

Low-Melting-Point Alloy Filling Support

Taking the part in Case 2 (Figure 6) as an example, this component is also made of GH4169 nickel-based high-temperature alloy and serves as a connecting ring in an aero engine. The part has a maximum diameter of 1331 mm, a minimum diameter of 1284 mm, and a total height of 31 mm.

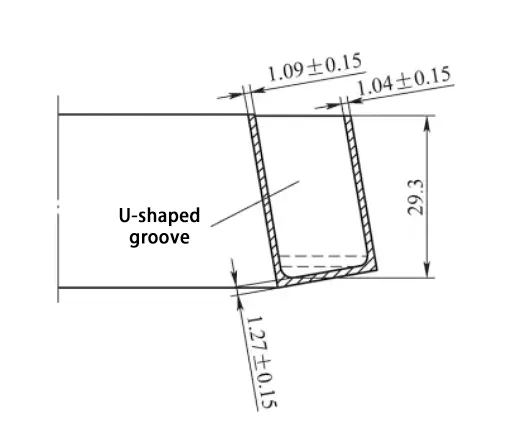

Its configuration features an inclined U-shaped structure with an axial depth of 29.3 mm in the U-shaped groove. The peripheral wall thickness ranges from 1.04 to 1.27 mm, with a tolerance of ±0.15 mm.

Machining Challenges and Strategy

When planning the turning sequence, direct machining presents a challenge: regardless of which section is turned first, the final wall thickness operation risks tool deformation due to insufficient part rigidity, compromising dimensional control.

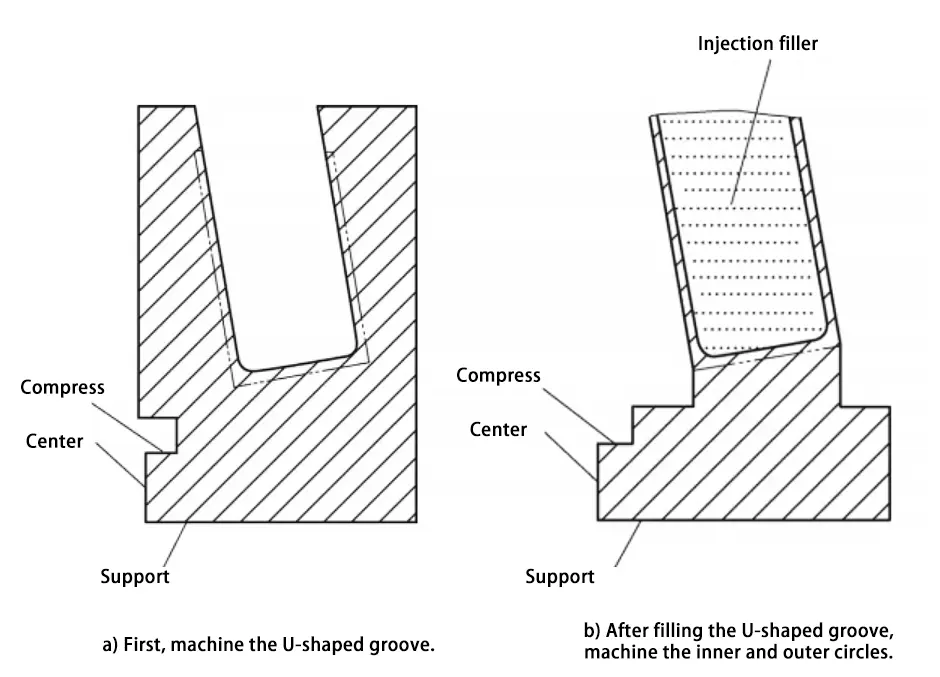

Given the part’s simple structure and rectangular blank, the fundamental approach is: turn an installation edge on the blank, then complete all finishing turns and cut-off operations in a single pass. The key challenge is enhancing rigidity at the machined areas.

The optimal approach to enhance rigidity is to first turn the ring groove, using supports to brace the U-shaped groove and ensure part rigidity. Subsequently, turn the inner and outer circles separately to guarantee wall thickness.

If the inner and outer circles were turned first before machining the U-shaped groove, designing a support solution for the circles would be challenging. The machining concept is illustrated in Figure 7.

Filling Material Evaluation

Regarding filler material selection:

– Using auxiliary fixtures for support poses challenges in designing a perfectly conforming structure. Even if feasible, precision requirements would drive costs significantly high.

Rubber filling aids vibration absorption and provides auxiliary support while conforming to the ring groove. However, rubber’s high elasticity limits its effectiveness for supporting such large, thin-walled ring components.

Improper use may even cause deformation before machining due to rubber’s high expansion coefficient, which could squeeze the part. A material with lower elasticity and higher hardness than rubber must be used for filling.

The initial choice was paraffin wax injection, a common method. After solidification, a 0.1–0.2 mm gap remained between the wax and the part wall, resulting in poor adhesion.

The system stiffness failed to meet expectations. During turning, this gap caused the machined area to move back and forth, making it impossible to guarantee the ±0.15 mm tolerance.

The second attempt involved pouring rosin as a reinforcing agent. Rosin filled the gaps almost completely, meeting machining requirements.

However, post-processing revealed that rosin required heating above 160°C to melt and remove, a temperature difficult to achieve in the machining environment.

The third attempt used gypsum as the reinforcement material. Although the surface gypsum solidified within 10 minutes after injection, the bottom layer remained unhardened, resulting in poor uniformity.

Achieving complete solidification required excessive time, significantly reducing work efficiency.

Final Selection: Low-Melting-Point Alloy

Therefore, a material was needed that could solidify uniformly within a short timeframe, possess a low coefficient of thermal expansion, exhibit high hardness, and allow for easy removal under conventional conditions after machining.

After repeated comparisons, a low-melting-point alloy primarily composed of lead, tin, and bismuth was selected.

This alloy features a low expansion coefficient, a melting point of only 70°C, and minimal thermal effects on part deformation during thermal filling, machining, and melting separation processes.

Operation Process

The entire operation process is as follows.

- Mount the workpiece on the machine tool while heating the low-melting-point alloy to a molten state using an electric furnace (or induction furnace).

- Pour the molten low-melting-point alloy into the part’s groove, filling it uniformly to the predetermined depth. The pouring process takes only 5 to 7 minutes.

- Allow the low-melting-point alloy to cool sufficiently (3 to 5 minutes).

- Inspect the surface for casting defects (including porosity, voids, and gaps between the alloy and part).

Verify internal dimensions; proceed with turning if no abnormal changes are detected. - After machining, immerse the part in a 70–80°C hot water bath to melt away the low-melting-point alloy, then perform dimensional and geometric accuracy checks.

- Recycle the low-melting-point alloy for reuse.

Verification confirms this method effectively maintains part rigidity, with wall thickness accuracy ±0.15mm relatively easy to achieve.

Although low-melting-point alloy requires pouring and recycling, it proves superior overall compared to paraffin, rosin, or plaster.

Conclusion

This article presents practical cases of controlling turning deformation in thin-walled high-temperature alloy rings through two methods: fixture-assisted support and filler material reinforcement.

Field verification confirms that selecting either support method based on specific conditions to enhance part rigidity not only meets dimensional accuracy requirements but also improves turning efficiency. This approach is recommended for similar thin-walled ring components.

FAQ

Which industries commonly use thin-wall turning?

Aerospace, medical device manufacturing, and electronics industries frequently use thin-wall turning to produce lightweight, high-precision components.

Why is thin-wall turning more challenging than conventional turning?

Thin-walled parts have low rigidity, making them susceptible to deformation, vibration, and chatter. These issues can reduce dimensional accuracy, surface finish, and tool life.

What machining strategies help reduce deformation in thin-walled parts?

Optimized cutting parameters, sharp tools, stable fixturing, constant tool pressure, step-by-step roughing and finishing, and specialized tool geometries all help minimize distortion during machining.

How do fixtures improve the machining of thin-walled ring components?

Fixtures that support the inner cavity increase part rigidity, reduce deformation caused by cutting forces, and help maintain wall-thickness accuracy during turning.

What role do filler materials play in enhancing rigidity?

Filler materials—such as rubber rings or low-melting-point alloys—reinforce hollow or thin areas of a part, significantly improving stiffness and suppressing machining vibrations.

Why was a low-melting-point alloy chosen over paraffin, rosin, or gypsum?

he low-melting-point alloy solidifies quickly, has low thermal expansion, provides high rigidity, is easy to remove at 70–80°C, and avoids the adhesion and removal problems seen with other fillers.

What are the main deformation control methods recommended for thin-walled high-temperature alloy rings?

The study recommends two proven methods: fixture-assisted support and filler-material reinforcement. Selecting the appropriate method based on the part’s structure effectively improves rigidity and ensures turning accuracy.