High-speed cutting technology has revolutionized the machining of aluminum alloy automotive components. As an advanced processing method, its cutting speeds typically exceed those of conventional cutting by 5 to 10 times, significantly enhancing machining efficiency and precision.

It addresses the shortcomings of traditional cutting methods, such as low processing efficiency, poor surface quality, and severe tool wear.

High-speed cutting enables the completion of more machining operations in a shorter timeframe, significantly reducing production cycles and substantially lowering manufacturing costs.

Furthermore, the majority of heat generated during high-speed cutting is dissipated through the chips, minimizing thermal deformation of the workpiece and thereby improving the surface quality of machined components.

It can be said that high-speed cutting technology not only substantially boosts machining efficiency and quality while lowering production costs, but also provides robust support for the precision manufacturing of automotive components.

Particularly in body structural components, engine parts, and suspension systems, the application of aluminum alloys not only contributes to reducing vehicle weight and improving fuel efficiency, but also significantly enhances vehicle safety and handling performance.

Overview of Aluminum Alloy Automotive Component Machining

Amid the automotive industry’s escalating demands for lightweighting, high performance, and environmental sustainability, aluminum alloys have emerged as an ideal material.

Their low density, high strength, and superior corrosion resistance have led to widespread adoption in automotive manufacturing, making them a key alternative to traditional cast iron and steel.

However, conventional machining techniques face limitations when processing aluminum alloy automotive components.

Importance of Aluminum Alloy Automotive Components

Amidst escalating global demands for energy conservation, emissions reduction, and environmental protection, the automotive industry urgently requires alternative materials that reduce vehicle weight while maintaining safety performance. Aluminum alloys emerge as an ideal choice due to their unique physical and mechanical properties.

First, compared to traditional steel materials, aluminum alloys possess a density approximately one-third that of steel. Using the same volume of aluminum alloy can significantly reduce overall vehicle weight.

Research indicates that a 10% reduction in vehicle weight can improve fuel efficiency by 6% to 8% and correspondingly decrease CO₂ emissions.

For advancing new energy vehicles, a lighter body increases electric vehicle range while reducing battery load.

Second, through proper alloying and heat treatment processes, the strength and toughness of aluminum alloys can be greatly enhanced.

High-strength aluminum alloys not only withstand substantial impact forces but also effectively absorb collision energy, safeguarding passenger safety.

Aluminum alloys’ excellent thermal conductivity and fatigue resistance make them ideal for manufacturing high-performance engine components like pistons and connecting rods, enhancing engine efficiency and reliability.

Third, vehicles encounter various harsh environmental factors during daily operation, which can cause metal components to rust and corrode, shortening their service life.

The dense oxide layer formed on the surface of aluminum alloys effectively prevents external substances from eroding the internal structure, extending component lifespan and reducing maintenance costs.

Finally, aluminum alloys can exhibit a wide range of colors and textures through different surface treatment techniques, meeting diverse market demands.

Limitations of Traditional Cutting Technologies in Aluminum Alloy Automotive Component Machining

Traditional cutting technologies face multiple constraints in machining aluminum alloy automotive components, including severe tool wear, high cutting forces and noticeable vibration, difficult chip removal, thermal deformation effects, and relatively high processing costs.

First, although aluminum alloys have lower hardness, machining generates significant heat, easily causing tool overheating and accelerating tool wear.

Particularly when machining complex geometries or high-precision components, frequent tool changes not only increase production costs but also prolong processing time, impacting overall productivity.

Second, aluminum alloys exhibit high plastic deformation tendencies, causing substantial cutting forces on workpiece surfaces that trigger intense vibration.

This vibration not only compromises machining accuracy and increases surface roughness but may also cause workpiece deformation or damage. Furthermore, vibration accelerates tool wear, shortening its service life.

Third, the chips produced during aluminum alloy cutting are typically long, thin strips or curled forms that easily wrap around tools or workpieces, obstructing normal machining processes.

If not promptly removed, these chips may re-enter the cutting zone, causing secondary cutting and further damaging both the tool and workpiece surfaces.

Due to these multiple factors, traditional cutting methods often require higher equipment investment, greater energy consumption, and more frequent tool changes, ultimately resulting in persistently high machining costs.

This cost disadvantage becomes particularly pronounced when facing large-scale production and high-quality requirements.

Principles and Advantages of High-Speed Cutting Technology

High-speed cutting (HSC) has become a key advancement in modern manufacturing, addressing the growing need for higher precision, better surface quality, and faster production.

Unlike conventional machining, HSC achieves superior efficiency by optimizing cutting speed, feed rate, tool materials, and machine performance.

Originally developed for aerospace and mold industries, HSC is now widely used in automotive and precision engineering to reduce machining time, improve accuracy, and minimize thermal distortion.

By combining advanced spindles, cutting tools, and control systems, high-speed cutting enables efficient, stable, and cost-effective production for a wide range of materials.

Principles of High-Speed Cutting Technology

High-speed cutting is a technology that achieves efficient machining by significantly increasing parameters such as cutting speed, feed rate, and depth of cut.

Compared to traditional cutting techniques, high-speed cutting relies not solely on increased speed but comprehensively considers the synergistic effects of material properties, tool design, machine tool performance, and cooling lubrication.

The fundamental principle of high-speed cutting lies in utilizing extremely high spindle speeds to minimize tool-workpiece contact time, thereby reducing heat generation and accumulation.

According to classical cutting theory, while cutting heat per unit time increases with higher cutting speeds, the extremely brief contact duration allows most heat to dissipate rapidly, resulting in limited actual temperature rise.

This phenomenon, known as the “cold cutting” effect, is crucial for maintaining high machining quality and extending tool life in high-speed cutting.

> Material Removal Mechanism and Chip Formation

Simultaneously, high-speed cutting alters traditional shear deformation patterns.

Under low-speed cutting conditions, chips are primarily formed through plastic flow of the material. In high-speed cutting, however, the drastic reduction in cutting forces causes the material to exhibit more brittle fracture characteristics.

The resulting chips are finer and more easily ejected, reducing the risk of secondary cutting and improving surface finish and flatness.

> Requirements for Equipment, Tools, and Cooling Systems

High-speed cutting requires machine tool spindles to accelerate rapidly within short timeframes. This necessitates the integration of machine tool spindles with motor spindles to form electric spindles for direct drive.

Electric spindles typically comprise a stator, rotor, rotary transformer rotor, rotary transformer stator, and cooling/lubrication systems.

The application of high-speed spindle technology enables cutting speeds exceeding ten times conventional rates, significantly boosting machining efficiency.

High-speed cutting imposes stringent demands on tool materials, which must exhibit higher hardness than the workpiece material while also possessing sufficient bending strength and wear resistance.

Common tool materials include cemented carbide, ceramics, cubic boron nitride, and polycrystalline diamond.

Furthermore, tool design must account for chemical stability and thermal deformation resistance under elevated temperatures.

Regarding cutting processes, appropriate parameters—such as cutting speed, feed rate, and depth of cut—must be selected to ensure both machining quality and efficiency.

Regarding cooling and lubrication methods, traditional wet cooling techniques used in conventional machining are unsuitable for high-speed cutting.

This is primarily because the extensive use of coolant leads to environmental pollution and resource waste.

Consequently, dry cutting and minimal quantity lubrication (MQL) have become the mainstream choices for high-speed machining.

Advantages of High-Speed Cutting Technology in Machining Aluminum Alloy Automotive Components

Aluminum alloy materials are increasingly prevalent in automotive components, providing robust support for vehicle lightweighting and energy efficiency.

However, the machining process for aluminum alloy automotive parts faces numerous technical challenges, such as low cutting efficiency and difficulty in ensuring machining accuracy.

High-speed cutting technology, by significantly increasing cutting speed and feed rate, not only drastically shortens processing cycles and enhances production efficiency but also effectively reduces cutting forces and thermal deformation.

This ensures the machining accuracy and surface quality of components.

It can be said that high-speed cutting technology offers distinct advantages in aluminum alloy automotive component machining, providing a more efficient, precise, and economical solution for manufacturing these parts.

> First, it enhances production efficiency.

Compared to traditional cutting methods, high-speed cutting removes more material within the same timeframe, significantly accelerating part processing speed.

For mass production, this translates to higher capacity utilization and lower unit costs. High-speed cutting enables simultaneous machining of multiple surfaces with a single setup, reducing non-productive time caused by frequent workpiece changes and further boosting efficiency.

Moreover, finer, more easily evacuated chips prevent clogging issues, lowering the frequency of downtime for cleanup and ensuring smoother overall machining processes.

> Second, it improves machining accuracy.

High-speed cutting applies smaller, more stable cutting forces, ensuring uniform stress distribution on the workpiece. This minimizes deformation or displacement, guaranteeing dimensional consistency and stability.

Simultaneously, it reduces vibration and impact effects, resulting in smoother, flatter machined surfaces.

By precisely controlling cutting parameters, high-speed machining achieves micron-level precision, meeting the exacting requirements of modern automotive components.

The fine chips produced during high-speed cutting prevent scratches or damage to the workpiece surface, enhancing product appearance quality.

High consistency is maintained between mass-produced parts, facilitating seamless integration on assembly lines and reducing rework or scrap caused by dimensional deviations.

> Third, it extends tool life.

Through the “cold cutting” effect and appropriate tool material selection, high-speed cutting effectively lowers tool operating temperatures, reduces wear, and prolongs tool service life.

High-speed cutting primarily induces brittle fracture in materials, minimizing plastic deformation that erodes tool edges and slowing tool dulling rates.

By optimizing cooling and lubrication methods, high-speed cutting better controls tool temperature, preventing tool failure caused by localized overheating.

Extended tool life means fewer tool changes, reduced tool procurement costs and inventory pressure, while also minimizing downtime for maintenance.

High-Speed Cutting of Aluminum Alloy Automotive Components

As automotive lightweighting advances, aluminum alloys have become essential for parts like engine blocks, wheels, and body structures.

While their strength and machinability offer major benefits, challenges such as tool wear and chip evacuation remain.

High-speed cutting (HSC) technology effectively addresses these issues by enabling faster material removal, superior surface quality, and higher dimensional accuracy.

The following sections highlight HSC applications in machining key aluminum alloy components, including engine blocks, wheels, and structural parts.

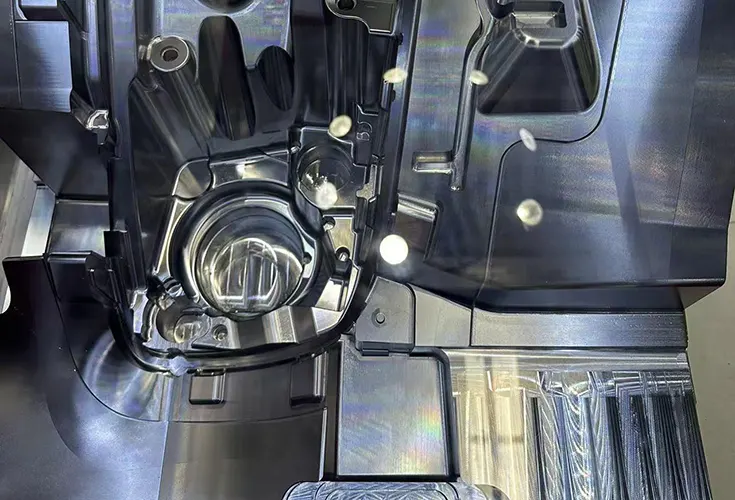

High-Speed Cutting of Engine Cylinder Blocks

The engine cylinder block is a critical component of automotive engines, characterized by complex structure, stringent precision requirements, and significant machining challenges.

Aluminum alloys, owing to their excellent castability and machinability, have become one of the primary materials for engine cylinder blocks. High-speed cutting technology plays a vital role in the manufacturing of these components.

Regarding material properties and machining requirements, cylinder block materials typically employ cast aluminum alloys like ZL111. This alloy offers high strength, excellent castability, gas tightness, and high-pressure resistance.

After heat treatment, it exhibits superior mechanical properties suitable for machining. Machining requirements for cylinder blocks include high precision, low surface roughness, and good dimensional stability.

The high-speed machining process for engine cylinder blocks typically involves the following steps: blank pre-machining, machining of the bottom surface and locating pin holes, machining of the main bearing cap mounting surface and crankshaft semi-circular holes, and finishing of cylinder bores and crankshaft holes.

During machining, it is essential to appropriately select machine tools, cutting tools, and cutting parameters to ensure both machining quality and efficiency.

For machine tools and cutting tools, high spindle speed, high feed rate, and high positioning accuracy are required to meet the high precision and efficiency demands of cylinder block machining.

Cutting tools should be selected from materials with excellent wear resistance, high strength, and good toughness, such as PCD tools.

Simultaneously, tool geometry and cutting parameters must be optimized based on the cylinder block material and machining requirements.

Regarding cutting fluid usage, a suitable fluid must be selected with controlled flow rate and pressure.

An effective cooling system must also be designed to ensure uniform fluid distribution over the cutting zone, enhancing cooling and lubrication efficiency.

High-Speed Cutting of Automotive Aluminum Alloy Wheels

Automotive aluminum alloy wheels are critical components whose quality and performance directly impact driving safety and comfort. High-speed machining technology plays a vital role in their manufacturing.

Regarding material properties and machining requirements, wheels typically use cast aluminum alloys like A356, which offer high strength, excellent castability, and corrosion resistance.

Processing requirements for wheels include high precision, low surface roughness, and excellent dimensional stability.

Key characteristics of high-speed machining for automotive aluminum alloy wheels include:

– Utilizing high-speed cutting tools and machine tools to enhance processing efficiency;

– Optimizing cutting parameters such as cutting speed, feed rate, and depth of cut to ensure quality and efficiency;

– Employing advanced fixtures and clamping methods to improve machining accuracy and stability;

and implementing effective cooling and lubrication measures to reduce cutting heat and friction resistance.

Regarding tool and machine selection for high-speed machining of automotive aluminum alloy wheels, tool materials with excellent wear resistance, high strength, and good toughness—such as PCD tools—must be chosen.

Simultaneously, tool geometric parameters and cutting parameters require rational optimization based on the wheel material and machining requirements.

Machine tools must feature high spindle speeds, high feed rates, and high positioning accuracy to meet the high precision and efficiency demands of wheel hub machining.

High-Speed Cutting of Aluminum Alloy Body Structural Components

Aluminum alloy body structural components are critical automotive elements, with their quality and performance directly impacting vehicle safety, comfort, and energy efficiency.

High-speed machining technology offers significant advantages in manufacturing these components.

Regarding material properties and machining requirements, body aluminum alloy structural parts are typically made from extruded or forged aluminum alloys, which exhibit excellent strength and toughness.

Machining requirements include high precision, low surface roughness, and good dimensional stability.

Key characteristics of high-speed machining for aluminum structural body components include: – Utilizing high-speed cutting tools and machine tools to enhance processing efficiency;

– Optimizing cutting parameters such as cutting speed, feed rate, and depth of cut to ensure quality and efficiency;

– Employing advanced fixtures and clamping methods to improve machining accuracy and stability;

– Implementing effective cooling and lubrication measures to reduce cutting heat and friction resistance.

For tool and machine selection, materials with excellent wear resistance, high strength, and good toughness—such as PCD tools—are required.

Simultaneously, tool geometry and cutting parameters must be optimized based on the structural component’s material and machining requirements.

Machines must also feature high spindle speeds, high feed rates, and high positioning accuracy to meet the high precision and efficiency demands of structural component machining.

Conclusion

High-speed cutting technology offers significant application advantages and broad development prospects in the machining of aluminum alloy automotive components.

Its implementation has substantially reduced processing cycles, enhanced machining quality, and further met the automotive industry’s demand for high-precision manufacturing.

With continuous technological advancement and expanding application domains, high-speed cutting technology will play an increasingly vital role in aluminum alloy automotive component manufacturing.

Overall, high-speed cutting technology—characterized by its efficiency, precision, and environmental friendliness—has substantially elevated the machining quality and production efficiency of aluminum alloy automotive components.

It effectively addresses the automotive industry’s urgent demands for lightweight, high-performance, and low-cost production.

FAQ

What is high-speed cutting technology in aluminum alloy machining?

High-speed cutting (HSC) is an advanced machining technology that operates at speeds 5–10 times faster than conventional cutting. By optimizing cutting speed, feed rate, and tool design, HSC significantly improves machining precision, reduces heat deformation, and enhances overall productivity in aluminum alloy automotive component manufacturing.

Why is high-speed cutting important for aluminum alloy automotive parts?

High-speed cutting is essential for machining aluminum alloys because it minimizes tool wear, improves surface finish, and shortens production cycles. It also supports the automotive industry’s goals of lightweighting, energy efficiency, and precision manufacturing.

How does high-speed cutting improve surface quality and precision?

HSC minimizes contact time between the tool and workpiece, allowing most cutting heat to dissipate through the chips. This “cold cutting” effect reduces thermal distortion, resulting in smoother surfaces and micron-level dimensional accuracy for engine blocks, wheels, and structural components.

What are the main advantages of high-speed cutting in automotive manufacturing?

Key benefits include higher machining efficiency, reduced production costs, longer tool life, superior surface finish, and improved dimensional stability. It enables faster production while maintaining or improving part quality.

What materials and tools are used in high-speed machining of aluminum alloys?

Cutting tools made from polycrystalline diamond (PCD), cemented carbide, ceramics, and cubic boron nitride (CBN) are commonly used. These materials offer high hardness, wear resistance, and thermal stability—essential for high-speed machining applications.

How does high-speed cutting reduce tool wear and extend tool life?

By operating at optimized speeds and using advanced tool materials, HSC reduces friction and heat buildup. The resulting lower cutting temperatures slow tool edge dulling, minimizing the frequency of tool changes and extending overall tool lifespan.

What role does cooling and lubrication play in high-speed cutting?

Traditional wet cooling methods are inefficient at high speeds and can cause environmental pollution. Instead, dry cutting and minimal quantity lubrication (MQL) systems are preferred to improve cooling efficiency, reduce friction, and enhance sustainability.

Which automotive components benefit most from high-speed cutting?

HSC is widely applied in machining engine cylinder blocks, aluminum alloy wheels, and body structural components. It ensures high precision, excellent surface finish, and faster throughput for these critical parts.

How does high-speed cutting contribute to automotive lightweighting?

By enabling precise machining of aluminum alloys—materials one-third the density of steel—HSC supports lighter vehicle designs. This reduces overall weight, improves fuel efficiency, extends EV range, and enhances safety through advanced material performance.

What is the future outlook for high-speed cutting in the automotive industry?

As electric and hybrid vehicles demand lightweight, high-precision components, high-speed cutting will continue to evolve. Future trends focus on smarter machining systems, tool material innovation, and greener lubrication technologies to further improve efficiency and sustainability.