What CNC machines use Fanuc controls?

Introduction

In the world of manufacturing, precision and efficiency are key factors that can make or break a project. CNC machines have revolutionized the way we produce parts and components, and the controls used in these machines play a crucial role in their operation.

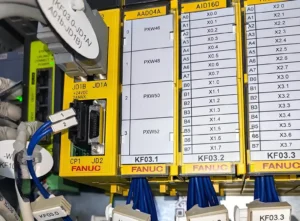

Fanuc controls are widely recognized as some of the best in the industry, known for their reliability, flexibility, and user-friendly interface.

In this article, we will explore what CNC machines use Fanuc controls and why they are so popular among engineers and manufacturers.

What is Fanuc?

Fanuc is a Japanese multinational corporation that specializes in providing CNC systems, robotics, and factory automation solutions.

The company is one of the largest manufacturers of industrial robots in the world, and its CNC systems are used in a wide range of industries, from aerospace and automotive to healthcare and electronics.

Fanuc controls are known for their advanced technology, high performance, and robust design, making them a preferred choice for many manufacturers.

Types of CNC Machines that Use Fanuc Controls

Fanuc controls are compatible with various types of CNC machines, including:

- Vertical machining centers

- Horizontal machining centers

- Turning centers

- Grinding machines

- Electrical discharge machines (EDM)

- Multi-axis machines

These machines utilize Fanuc controls to program and operate the cutting tools, motors, and other components with precision and accuracy.

Whether you are working on simple milling operations or complex multi-axis machining, Fanuc controls offer the versatility and performance needed to handle a wide range of applications.

Advantages of Using Fanuc Controls

There are several key advantages to using Fanuc controls in CNC machines:

- Reliability: Fanuc controls are known for their reliability and durability, ensuring consistent performance even in demanding manufacturing environments.

- Flexibility: Fanuc controls are highly customizable, allowing engineers to tailor the programming to meet specific requirements and optimize production processes.

- User-friendly interface: Fanuc controls feature an intuitive interface that is easy to learn and navigate, reducing the learning curve for operators and programmers.

- High-speed processing: Fanuc controls are capable of high-speed processing, enabling faster cycle times and increased productivity.

- Advanced features: Fanuc controls offer a range of advanced features, such as tool path optimization, collision avoidance, and adaptive control, to enhance machining capabilities and efficiency.

These advantages make Fanuc controls an ideal choice for manufacturers looking to maximize their machining capabilities and improve overall operational performance.

Popular CNC Machine Brands that Use Fanuc Controls

Many leading manufacturers of CNC machines rely on Fanuc controls to power their equipment. Some of the most popular CNC machine brands that use Fanuc controls include:

- Haas Automation

- Mazak

- Doosan

- Okuma

- Mori Seiki

- DMG Mori

These brands have chosen Fanuc controls for their proven performance, advanced capabilities, and overall quality, making them a top choice for engineers and manufacturers around the world.

Conclusion

In conclusion, Fanuc controls are a staple in the world of CNC machining, offering a combination of reliability, flexibility, and advanced features that set them apart from other control systems.

Whether you are working on simple milling operations or complex multi-axis machining, Fanuc controls provide the versatility and performance needed to achieve superior results.

With a user-friendly interface, high-speed processing, and a wide range of customizable options, Fanuc controls are the preferred choice for engineers and manufacturers looking to optimize their machining processes and improve overall efficiency.

By understanding what CNC machines use Fanuc controls and the advantages they offer, you can make informed decisions when selecting the right equipment for your manufacturing needs.

FAQ

What is Fanuc, and why is it so popular in the CNC machining industry?

Fanuc is a Japanese multinational corporation specializing in CNC systems, robotics, and factory automation solutions. It is widely recognized for its reliability, flexibility, and high-performance CNC controls, making it a popular choice for engineers and manufacturers in industries ranging from aerospace to automotive.

Which types of CNC machines use Fanuc controls?

Fanuc controls are compatible with various CNC machines, including vertical and horizontal machining centers, turning centers, grinding machines, electrical discharge machines (EDM), and multi-axis machines. Their versatility makes them suitable for a wide range of applications, from simple milling operations to complex multi-axis machining.

What are the key advantages of using Fanuc controls in CNC machines?

Fanuc controls are known for their reliability, flexibility, and user-friendly interface. They offer high-speed processing, advanced features such as tool path optimization and collision avoidance, and customization options, all of which help engineers enhance efficiency, reduce cycle times, and improve overall machining capabilities.

Which CNC machine brands rely on Fanuc controls?

Several leading CNC machine brands use Fanuc controls, including Haas Automation, Mazak, Doosan, Okuma, Mori Seiki, and DMG Mori. These manufacturers trust Fanuc for its proven performance, advanced features, and overall quality, making it the go-to choice for many industries worldwide.

How do Fanuc controls improve the machining process?

Fanuc controls help optimize production processes by providing reliable and high-speed processing capabilities. With advanced features like adaptive control, collision avoidance, and tool path optimization, Fanuc systems improve precision, enhance machining efficiency, and reduce the risk of errors or downtime.

Why are Fanuc controls considered user-friendly?

Fanuc controls are designed with an intuitive interface that is easy to learn and navigate. This reduces the learning curve for operators and programmers, helping them quickly get up to speed and improving overall productivity. Whether you're a beginner or an experienced operator, Fanuc makes CNC machine operation simpler and more efficient.

2 thoughts on “What CNC machines use Fanuc controls?”

Definitely sending this to my manager.

I feel smarter already.

Comments are closed.