Can CNC machines cut fabrics and textiles?

Can CNC Machines Cut Fabrics and Textiles

The advent of technology has revolutionized the manufacturing industry, offering innovative solutions to traditional processes.

One such technology that has garnered attention is Computer Numerical Control (CNC) machines, which are commonly used in woodworking, metalworking, and other solid materials.

However, can CNC machines be used to cut fabrics and textiles effectively?

This article takes a deep dive into how CNC machines are used for cutting fabrics and textiles, exploring their precision, efficiency, and role in modern manufacturing.

Understanding CNC Machines

Before delving into the realm of fabric and textile cutting, it is essential to understand what CNC machines are and how they operate.

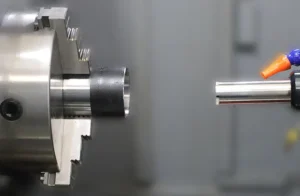

CNC machines are automated systems that use computer programs to control various machining tools such as drills, lathes, and mills.

These machines can produce precise and complex cuts based on the inputted design.

Challenges

Cutting fabrics and textiles poses unique challenges compared to cutting solid materials. Fabrics are flexible, delicate, and prone to fraying.

Traditional cutting methods such as scissors or rotary cutters may not always yield precise and consistent results, especially when dealing with intricate designs.

Role of CNC Machines in Fabric and Textile Cutting

Despite the challenges, CNC machines have shown promising capabilities in cutting fabrics and textiles.

With the right settings and tools, CNC machines can overcome the limitations of traditional cutting methods and deliver precise cuts on various types of fabrics.

Advantages

There are several advantages to using CNC machines for fabric and textile cutting:

- Precision: CNC machines can execute intricate designs with high precision, ensuring consistency in cuts.

- Efficiency: CNC machines can automate the cutting process, saving time and reducing labor costs.

- Versatility: CNC machines can cut a wide range of fabrics, from soft materials like silk to tougher textiles like denim.

- Customization: CNC machines offer the flexibility to cut custom designs and patterns, catering to specific requirements.

Considerations for Cutting Fabrics and Textiles

When using CNC machines for cutting fabrics and textiles, several factors need to be considered to achieve optimal results:

- Choice of Cutting Tool: Selecting the right cutting tool is crucial to prevent fraying and ensure clean cuts. Options include rotary cutters, drag knives, and laser cutters.

- Tension Control: Maintaining proper tension on the fabric is essential to prevent distortion during cutting. Improper tension can lead to inaccurate cuts and wasted material.

- Speed and Feed Rates: Adjusting the speed and feed rates of the CNC machine can impact the cutting quality. Finding the optimal settings for different fabrics is key to achieving desired results.

- Surface Support: Providing adequate support for the fabric during cutting is necessary to prevent shifting or wrinkling. Using a cutting mat or backing material can improve stability.

Applications

CNC machines have been utilized in various industries for fabric and textile cutting, including:

- Apparel Manufacturing: CNC machines can cut fabric pieces for garments with high accuracy, reducing material waste and improving efficiency.

- Home Textiles: CNC machines can create intricate patterns on textiles used for home decor, such as curtains, upholstery, and bedding.

- Automotive Upholstery: CNC machines are used to cut fabric and leather components for automotive interiors, ensuring precise fit and finish.

- Outdoor Gear: CNC machines can cut technical fabrics for outdoor gear like backpacks, tents, and outdoor apparel, meeting specific performance requirements.

Conclusion

In conclusion, CNC machines have demonstrated their efficacy in cutting fabrics and textiles, offering precision, efficiency, and versatility in the manufacturing process.

By understanding the unique challenges and considerations involved in fabric cutting, manufacturers can leverage CNC technology to enhance their production capabilities and deliver high-quality products.

As technology continues to evolve, CNC machines are expected to play a vital role in the future of fabric and textile cutting, driving innovation and productivity in the industry.

1 thought on “Can CNC machines cut fabrics and textiles?”

Sending this to our new hire.