In mass production, hole machining processes—including drilling, reaming, and chamfering—involve lengthy workflows, numerous machines, and excessive tooling, resulting in low efficiency and high costs.

Most enterprises adopt a dispersed, multi-setup machining approach, making it difficult to guarantee hole precision.

This results in low automation levels and processing efficiency, weakening product competitiveness in the market. Therefore, engineers are considering consolidating machining processes by using composite tools.

Current manufacturing processes

The current hole machining process involves separate drilling, reaming, and chamfering operations. Drilling precedes reaming, followed by chamfering, requiring three setups and three tool changes.

The primary drawbacks include:

-

Low machining accuracy

Three setups and three tool changes alter machining references, compromising hole coaxiality and dimensional precision.

-

Low productivity

Multiple setups and tool changes increase auxiliary processing time for tool changes, tool alignment, and sharpening, resulting in heavy workloads and reduced efficiency.

-

Higher batch production costs

Using multiple machines and tools increases the number of machines and tools required, demanding higher technical skills from operators.

Due to the complexity of designing and manufacturing hole-processing tools that combine different tool types, existing patents and research results mostly involve welded tools.

These tools also typically use different cutting parameters during operation, so no composite tool identical to this design currently exists.

Tool Body Structural Principle Design

This tool design aims to provide a high-efficiency, high-precision, low-cost composite tool integrating drill, reamer, and chamfering functions.

The tool comprises a cutting head and shank. The cutting head combines a twist drill, reamer, and chamfering section.

The reamer features four helical cutting edges, while the shank is straight. The entire tool adopts an integral structure.

-

Drilling Section

Leveraging the high drilling efficiency of twist drills for internal holes, this tool retains the traditional twist drill structure for its drilling section. The helix angle of the flute is 30°.

A 0.02~0.04 mm undercut is ground on the side cutting edge to reduce friction, enabling chips generated at the cutting edge to be efficiently guided into the flute for evacuation.

This section performs rough machining of the hole, producing surfaces with relatively poor surface roughness and hole straightness, along with lower dimensional accuracy. It prepares the workpiece for subsequent reaming operations.

-

Reaming Section

A four-flute, double-edged external chip-evacuation reamer is employed. Each cutting edge consists of a precision primary cutting edge and a secondary cutting edge.

During operation, the primary cutting edge performs the main cutting action, while the secondary cutting edge provides finishing. The reaming section follows drilling to complete the hole’s finishing, ensuring dimensional accuracy (geometric accuracy and surface roughness).

-

Chamfering Section

After hole finishing, a chamfering tool is used to chamfer the hole. Chamfering is preferably performed under manual control.

Since this composite tool is typically used for machining smaller-diameter holes, the tool shank (i.e., the holder) is designed as a straight shank.

To facilitate chip evacuation and prevent simultaneous cutting by all tool sections (reducing cutting forces), the starting points of the cutting sections on each tool are spaced axially.

This also increases chip clearance space, ensuring smooth chip removal and preventing interference or blockage between chips cut by the front and rear cutting faces.

Additionally, appropriate clearance grooves must be provided for grinding wheels during tool manufacturing.

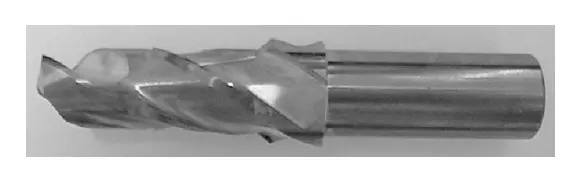

Tool dimensions are determined based on the specific hole size. For example, the tool design shown in Figure 1 is for machining a ⌀16 (+0.04/0) mm hole.

Cutting Edge Parameters Setting

The parameters of the cutting edge significantly impact tool life, machining difficulty, and machining accuracy. They also directly influence processing costs and efficiency. Therefore, each cutting parameter must be selected appropriately.

(1) Drilling Section: To ensure the drill bit’s core strength, the rake angle is set to 118°. Typically, the front angle is 0°~5° and the back angle is 6°~8°. This configuration expands the chip-carrying space, reduces friction between the drill bit and hole wall, while maintaining the strength of the secondary cutting edge.

(2) Reaming Section: Due to minimal reaming allowance and extremely thin chips with brief contact against the rake face, the front angle has limited effect. For manufacturing convenience, the front angle is set at 0°–5°, the back angle at 6°~8°, and the cutting edge width at 0.2~0.3 mm. The reamer features four cutting teeth with right-hand spiral cutting edges.

To ensure stable reamer operation, improve surface finish quality, and facilitate smooth chip evacuation from the reamer’s front face during cutting, chip scratches on the hole wall can be avoided, and hole expansion can be minimized.

Selection of Tool Material for the Cutting Section

The tool structure adopts an integral design, thus requiring appropriate tool material selection based on the properties of the workpiece material, production characteristics, and cutting conditions.

The drilling section primarily handles rough machining with greater cutting depth, subjecting the tool to higher cutting forces and lower cutting speeds. Thus, materials with higher strength, superior impact resistance, vibration damping properties, and wear resistance are recommended.

The reaming section primarily performs finishing operations to stabilize dimensions. Cutting speeds at the cutting edge are relatively higher than during drilling, while cutting depth is reduced. Therefore, materials with excellent wear resistance and heat resistance are preferred.

For these reasons, both the tool shank and cutting section utilize W18Cr4V high-speed steel.

This material is a tool steel characterized by high hardness, wear resistance, and heat resistance.

It offers excellent machinability with a balanced combination of strength and toughness. It is primarily used for manufacturing complex thin-edge and impact-resistant metal-cutting tools, as well as high-temperature bearings and cold extrusion dies.

Tool Manufacturing

The precision of composite tools directly impacts the quality of machined holes (geometric accuracy and surface roughness).

To maximize the effectiveness of composite tools, their inherent precision must be ensured, necessitating the establishment of feasible manufacturing processes for the tools themselves.

- Manufacturing process

To achieve the required comprehensive mechanical properties (sufficient strength combined with high toughness) and ensure dimensional stability, the general manufacturing process is: Rough turning of the tool body → Quenching and tempering treatment → Finish turning of the tool body → Milling the spiral flute section of the drill → Milling the cutting section of the reamer → Quenching + tempering (hardness 62-66 HRC) → Grinding the drill’s outer diameter → Grinding the reamer’s cutting edge → Grinding the 45° chamfered edge → Grinding the shank → Removing the false center point, manually grinding the 118° cutting angle.

Due to the complex structure of the drill’s helical flute section and the reamer’s cutting section, machining their contour curves presents challenges. Traditional machine tools may struggle with these operations, so advanced CNC milling machines or machining centers are recommended for processing.

Select an automatic programming method to create a 3D solid model of the tool, as shown in Figure 2. Post-process the model to generate an automatic machining program, then complete the machining on a CNC milling machine or machining center.

The remaining machining steps for the tool, such as grinding the tool’s outer diameter, grinding the reamer’s cutting edge, chamfering the cutting edge, grinding the shank, and grinding the cutting angle, are similar to traditional machining methods.

Through the aforementioned machining process, manufacturers can produce this composite drill-reamer-chamfering tool with high precision, fully leveraging its performance. Figure 3 shows the finished tool.

Selection of Cutting Parameters

Since the tool integrates drilling, reaming, and chamfering functions, operators should apply consistent cutting parameters across all sections.

Toolmakers determine the cutting depth (ap) during manufacturing based on the actual workpiece dimensions.

Feed rate f should consider machine power, feed mechanism strength, and tool strength. For drilling, select f = 0.04~0.06 mm/r;

Cutting speed v should balance tool life and hole quality. The selected value is 20~25 m/min.

Novelty of the Drill-Reamer-Chamfering Composite Tool

The tool comprises three components—a drill bit, a reamer, and a chamfering section—all fabricated from the same material as a single unit. This design offers simplicity, ease of manufacturing, and lower costs.

The drill bit is a standard twist drill, while the reamer features a spiral cutting edge with four teeth. Primarily designed for machining straight holes, the integrated chamfering section enables processing of various hole types.

Since the tool integrates drilling, reaming, and chamfering functions, operators can use identical cutting parameters throughout the process without making adjustments. This approach saves machining time and reduces operator fatigue.

Advantages of Drill-Reamer-Chamfering Composite Tools

The reference point remains unchanged throughout multiple machining operations, ensuring high positional accuracy between workpiece surfaces. This also guarantees superior hole diameter precision, hole wall straightness, and surface roughness.

By consolidating processes, composite tools reduce auxiliary processing time—such as tool changes, alignment, and sharpening—saving both machine and auxiliary hours while significantly boosting production efficiency.

Batch production costs are lower. Tool wear is minimal, reducing the number of workstations, machines, and tools required, while also lowering the technical skill demands on operators.

Based on this tool design, engineers can modify the structure and tool materials to machine various hole types in different materials on different machine tools.

This tool is an integral tool, and its manufacturing process is simpler than that of welded or mechanically clamped tools.

Conclusion

This study presents the design and implementation of an integrated drill-reamer-chamfering composite tool that effectively addresses the inefficiencies of traditional hole machining processes.

By combining drilling, reaming, and chamfering into a single operation, the tool eliminates multiple setups, tool changes, and reference shifts—significantly improving machining accuracy, productivity, and cost efficiency.

The tool’s integral structure, made from W18Cr4V high-speed steel, ensures excellent strength, wear resistance, and thermal stability.

Optimized cutting edge geometry and parameter settings further enhance tool performance, enabling smooth chip evacuation, reduced cutting forces, and extended tool life.

The proposed manufacturing process, supported by CNC machining and precision grinding, guarantees high tool accuracy and reliability.

As a result, the composite tool achieves precise hole geometry, superior surface finish, and consistent dimensional control, while reducing labor intensity and production costs.

Overall, this drill-reamer-chamfering composite tool demonstrates significant advantages in efficiency, precision, and economic value, offering a practical and scalable solution for modern mass-production environments.

Future research can explore material optimization and tool geometry refinement to expand its applications across diverse workpiece materials and machining conditions.

FAQ

What problem does the drill-reamer-chamfering composite tool solve?

It addresses the inefficiencies of traditional hole machining processes that require multiple setups and tool changes, which often lead to low accuracy, high costs, and long production times.

How does this composite tool improve machining efficiency?

By integrating drilling, reaming, and chamfering functions into a single tool, it eliminates repeated setups and tool changes, significantly reducing auxiliary time and improving overall productivity.

What are the main advantages of using a composite tool over traditional methods?

The composite tool ensures higher hole precision, better surface finish, improved coaxiality, reduced operator workload, and lower batch production costs.

What material is used to manufacture the tool?

The tool is made from W18Cr4V high-speed steel, which offers excellent hardness, wear resistance, and heat resistance, making it ideal for high-performance machining.

What is the structural composition of the composite tool?

It consists of an integrated cutting head and shank, with the cutting head combining three sections—a drill, a reamer, and a chamfering cutter—designed for high precision and durability.

How does the tool maintain hole accuracy and surface quality?

Since all machining operations share a single reference point, the tool ensures excellent hole coaxiality, dimensional stability, and superior surface roughness.

What are the typical cutting parameters for this tool?

The recommended parameters are:

Feed rate (f): 0.04–0.06 mm/r

Cutting speed (v): 20–25 m/min

Cutting depth (ap): Determined by workpiece dimensions during manufacturing.

How is the tool manufactured?

The tool is produced through CNC machining and precision grinding, following a process that includes turning, heat treatment, flute milling, quenching, and grinding to ensure dimensional stability and cutting accuracy.

Can the tool be customized for different applications?

Yes. The structure and material of the tool can be modified to suit various workpiece materials, hole sizes, and machine tool types.

What are the key benefits of implementing this tool in mass production?

It offers higher efficiency, better precision, longer tool life, and lower production costs—making it an ideal solution for modern automated and large-scale manufacturing environments.