In precision thin-sheet processing, have you ever been troubled by part deformation and uncontrollable accuracy?

Whether it’s lightweight components in aerospace or ultra-thin elements in electronic devices, machining thin-sheet parts invariably faces a core challenge: how to maintain dimensional stability and surface integrity under the combined forces of cutting and clamping?

Drawing from multiple real-world machining cases, this article systematically outlines comprehensive process solutions—from simple thin plates and complex structural components to ultra-thin foils.

By optimizing clamping designs, adjusting machining strategies, and incorporating flexible supports, we successfully controlled deformation while achieving dual improvements in quality and efficiency.

Whether you’re a process engineer or a frontline operator, these practical insights from the production floor will undoubtedly provide valuable inspiration.

Machining Simple Thin Plate Parts

Simple thin plate parts are typically small with straightforward geometries. Due to their diminutive size, they cannot be cut as individual pieces and are unsuitable for clamping with universal fixtures like vices.

These parts generally require finishing on six faces. However, multiple setups can introduce clamping errors, compromising both efficiency and quality.

Through research and experimentation, the following machining methods were developed:

1) Large plate during blanking

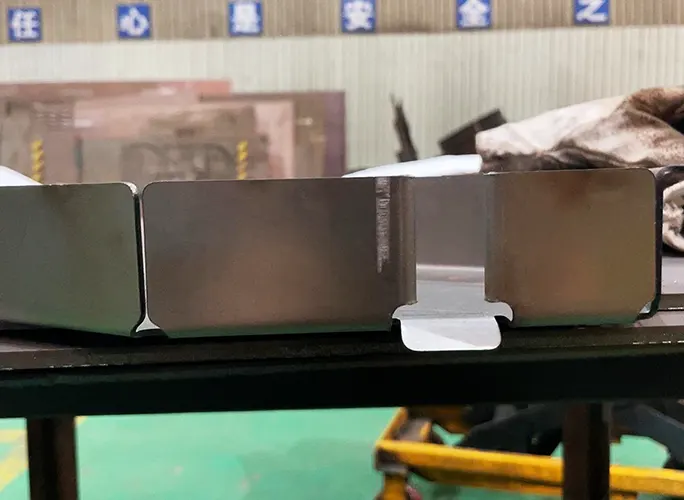

Cut a large plate during blanking to produce multiple workpieces.

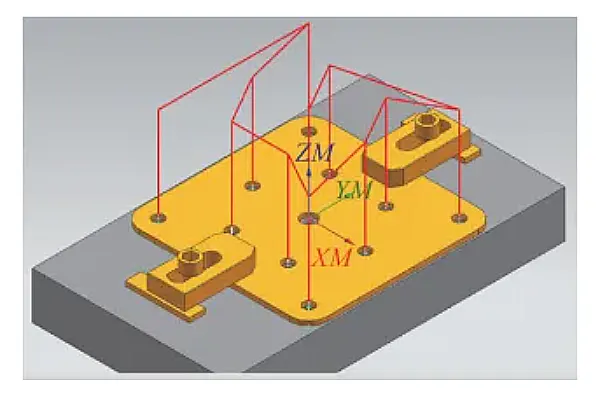

Fabricate a fixture plate (see Figure 1), clamp the plate onto the fixture plate using pressure plates, and precision-mill both end faces.

2) Adjustable-length clamping plates

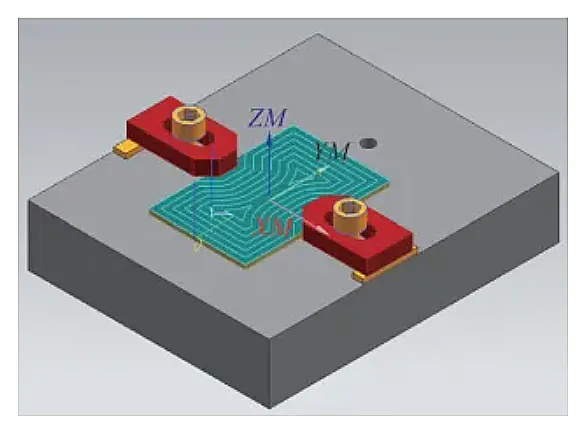

Employ adjustable-length clamping plates to provide auxiliary support during machining.

This prevents workpieces from detaching from the base plate and causing tool collisions upon milling completion. The milling paths for the workpiece’s outer contour are illustrated in Figure 2.

Machining Complex Thin-Plate Parts

Complex thin-plate parts involve multiple machining elements, typically including hole patterns, slots, or steps.

During machining, auxiliary holes can be effectively created using features like through-holes or through-slots. Parts are clamped and positioned using screws, shims, and bosses on the fixture.

By shifting clamping positions, complete machining of all areas is ensured while maintaining consistent clamping throughout the process.

The machining plan for a specific complex thin-plate part is as follows.

1) Manufacturing workbenches

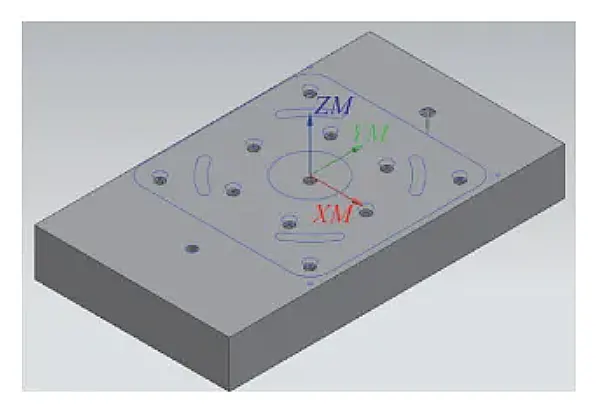

Design and fabricate a fixture plate based on the part’s final machined profile (see Figure 3).

Pre-drill holes for locking screws and clamping plate screws on the fixture plate.

2) Pre-machined hole

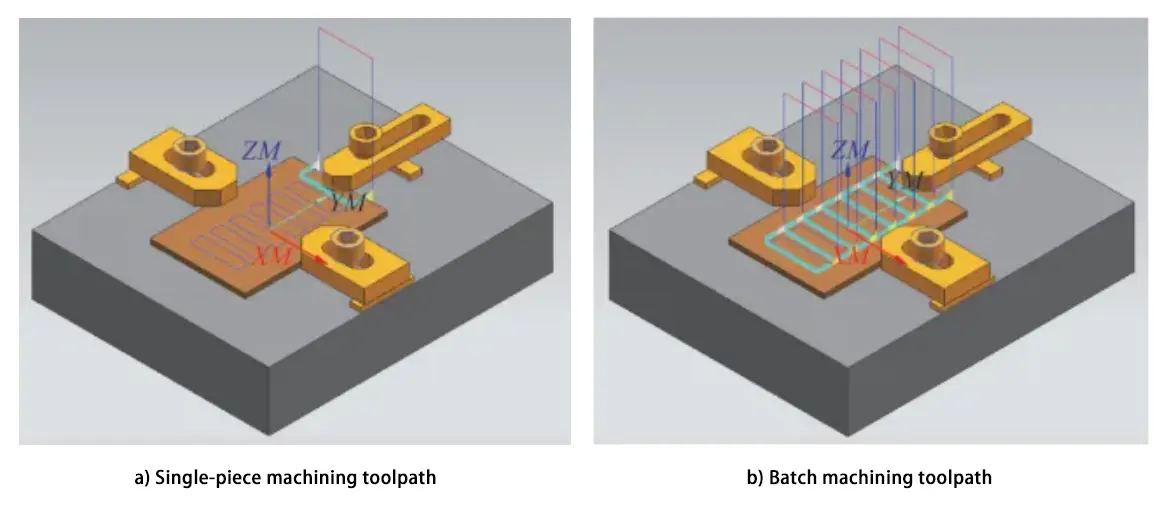

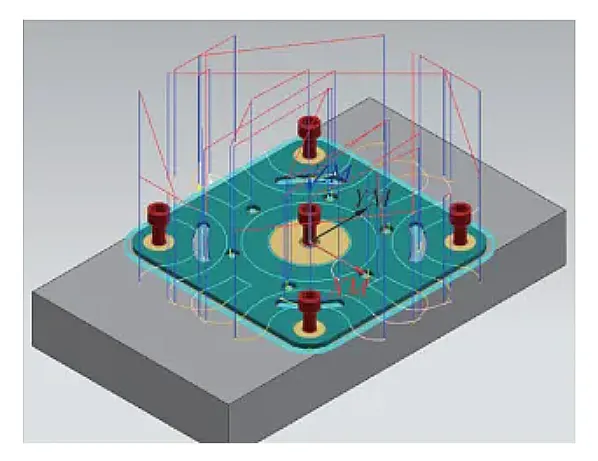

Clamping for the first machining operation is shown in Figure 4.

Use clamping plates to secure the workpiece onto the fixture plate, ensuring roughly correct orientation.

Machining allowance is left on the pre-machined holes (with machining allowance retained for hole dimensions).

3) Processing Step 2

For the second machining process, clamp the part as shown in Figure 5.

Secure the workpiece using four perimeter screws and one central screw, remove the side clamping plates, and perform precision milling on the top face, holes, slots, and outer contour.

4) Processing Step 3

For the third machining operation, as shown in Figure 6, remove the original screws and install six inner screws.

Use the two end clamping plates for auxiliary clamping.

Finish mill the interference areas on the upper end face from the previous step, as well as the four peripheral holes and the central large hole, completing the machining.

Figure 6: Clamping Diagram for Part 3 of Part Processing

This solution addresses the challenge of clamping complex thin-plate workpieces.

For thin-plate parts with thicknesses of 3–5 mm, it enables simultaneous processing of multiple parts in a single setup. This approach not only ensures consistent product quality but also significantly enhances processing efficiency.

Ultra-Thin Sheet Metal Part Machining

Ultra-thin sheet metal parts measure only 0.05–0.15 mm thick, typically made of stainless steel or non-ferrous metals and used as washers or gaskets.

Their extreme thinness precludes conventional mechanical clamping methods during machining. To address their structural characteristics, raw materials are procured as plates matching the part thickness.

These are manually cut to size and secured using upper and lower clamping plates with screws for multi-layer locking. Alternatively, they are fixed via welding under clamping force.

A machinist drills through-holes, after which wire EDM machines perform processing: first threading wire through the through-holes for precision cutting of internal holes, then threading wire from the exterior for precision cutting of the outer shape.

The specific workflow is as follows:

1) Clamp the cut sheet material between upper and lower pressure plates (see Figure 7), securing it via welding or screws.

2) Perform electrical discharge machining using a wire EDM machine. First, thread the wire through the central hole to precision-cut the part’s inner bore.

Then, thread the wire from the outer side to precision-cut the part’s outer contour. The inner hole and outer contour after wire cutting are shown in Figure 8.

Through the above operations, precision machining of ultra-thin sheet metal parts can be achieved. Figure 9 shows the finished product with a part thickness of 0.1mm.

Conclusion

The thin-plate components discussed in this paper are too delicate for conventional mechanical clamping methods.

Consequently, several efficient and practical machining solutions were developed. These approaches were rigorously validated through repeated testing in actual production.

By employing appropriate clamping techniques and machining methods, the challenges of processing ultra-thin plate components and addressing clamping deformation in complex thin-plate parts were effectively resolved.

This approach reliably ensures the machining quality of thin-plate components while enhancing overall production efficiency.

FAQ

Why do thin-sheet metal parts deform easily during CNC machining?

Thin-sheet components—especially those used in aerospace and electronics—are highly prone to deformation because of their low stiffness. Cutting forces, clamping pressure, thermal effects, and tool vibration can distort the part, making dimensional accuracy hard to control. Proper fixture design, optimized toolpaths, and supplemental support are essential to maintain stability.

What machining strategies help prevent deformation in simple thin plate parts?

For simple thin plates, the most effective techniques include machining multiple parts from a larger blank, using fixture plates with pressure clamps, and adding adjustable-length clamping plates for auxiliary support. These methods reduce clamping errors, prevent part lift-off, and ensure accurate machining of all six faces.

How do you achieve high precision when machining complex thin-sheet components?

Complex thin-plate parts often require multi-step clamping strategies. Using pre-machined holes, custom fixture plates, and adjustable screws allows stable repositioning without losing reference accuracy. By shifting clamping points and performing operations in stages, all features—holes, slots, steps, and contours—can be finished with consistent precision.

What is the best way to machine ultra-thin sheet metal parts (0.05–0.15 mm)?

Ultra-thin parts are too flexible for conventional clamping. The recommended method is multilayer locking: sandwiching the sheets between upper and lower pressure plates using screws or welding. Machining is then completed with wire EDM, cutting internal holes first and exterior contours second. This ensures burr-free edges and excellent dimensional stability.

How do custom fixtures improve accuracy in thin-sheet CNC machining?

Custom fixtures—such as dedicated fixture plates, pressure plates, and flexible supports—distribute clamping force evenly and reduce distortion. They allow precise positioning, stable machining of multiple parts at once, and easier control of deformation caused by cutting forces. This directly improves repeatability and product quality.

How can manufacturers improve both quality and efficiency when machining thin-sheet parts?

Efficiency and quality are improved by combining optimized clamping designs, multi-part setups, staged machining processes, and advanced methods like wire EDM for ultra-thin materials. These techniques minimize deformation, reduce rework, ensure consistent quality, and significantly shorten machining time—especially valuable for aerospace, electronics, and high-volume manufacturing.