CNC Machining Services forUSA

Get your high-performance parts today

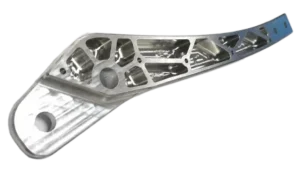

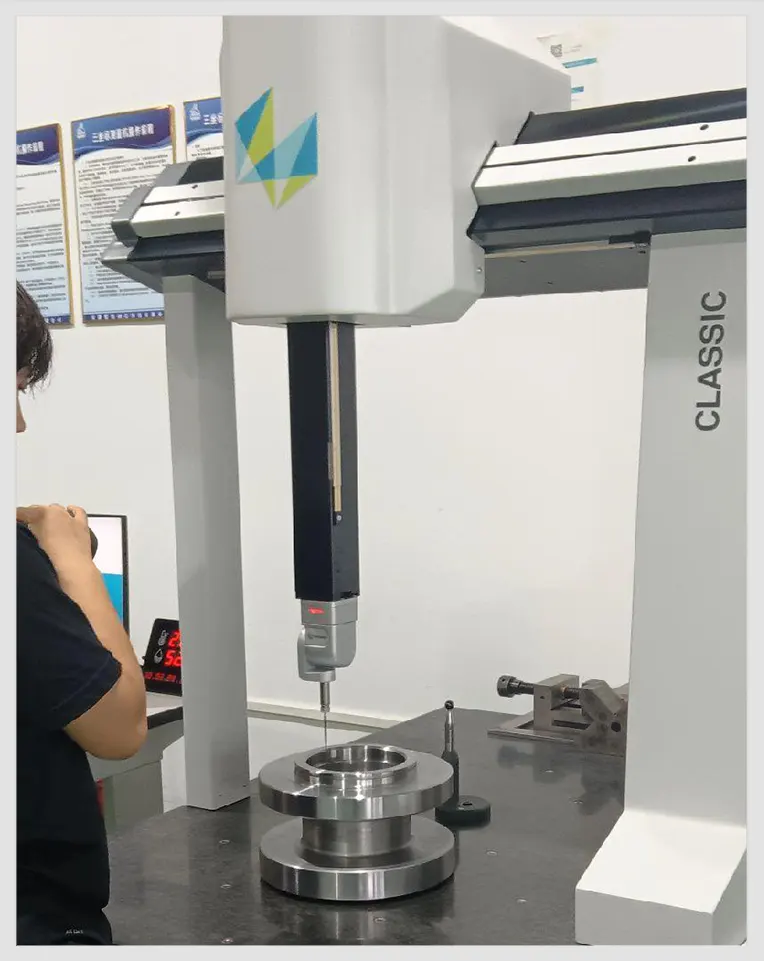

Welcome to TonzaMaking, your premier provider of CNC machining services. With years of experience in precision machining, we strive to deliver top-quality products to our customers. Our state-of-the-art facility is equipped with the latest technology to ensure we meet your machining needs efficiently and accurately.

At TonzaMaking, we pride ourselves on our commitment to excellence in CNC machining. Our team of skilled technicians is dedicated to producing high-quality parts and components for a wide range of industries. Whether you need prototyping, production runs, or custom machining services, we have the expertise and equipment to get the job done right.

When you choose TonzaMaking for your CNC machining needs, you can trust that you are getting the best service in the industry. Contact us today to learn more about how we can help you with your machining projects.

Type of CNC Machining Services for USA

The study of language is essential for effective communication and understanding among individuals. It involves the analysis of the structure, function, and evolution of languages spoken by different communities worldwide. Linguists study various aspects of language such as phonetics, morphology, syntax, semantics, and pragmatics to better comprehend how languages work.

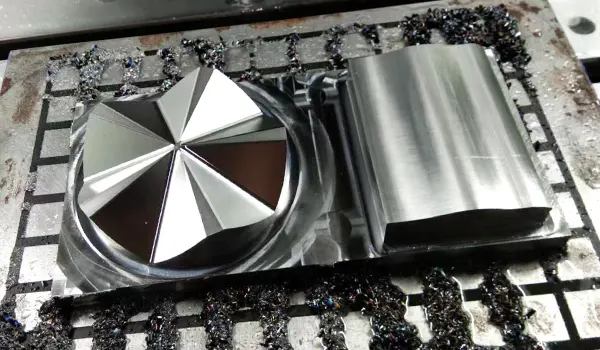

CNC Milling services

CNC Turnning services

5-Axis CNC Machining

Precision Machining Services

Capabilities of CNC Machining Services for USA

Our CNC machines produce parts with micron-level precision that certified to international standards, optimizing fit and function with tight tolerances.

Tolerances

±0.05mm

Artful integration of advanced systems to provide you with reliable quality you can trust.

Max part size

200 x 80 x 100 cm

Fitted with the latest manufacturing technology, focused on fulfilling unique customer demands

Wall Thickness

0.75 mm

Extensive hands-on experience, versatile in dealing with high-complexity parts.

Lead Time

< 10 days

Well-coordinated team management, and rapid turnaround times

Why Choose Ours CNC Machining Services?

delivering exceptional results through experience, dedication, and strategic thinking.

working closely with clients to understand their unique needs and goals

featuring the latest technology and advanced machinery to ensure precision, efficiency.

delivering exceptional value without compromising on quality or precision.

CNC Machining Solutions for USA

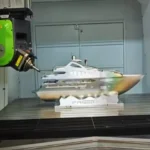

We provide customized manufacturing solutions to address individual customer requirements, such as quick prototyping, transitional production, and large-scale mass manufacturing. Our comprehensive services cater to diverse needs, ensuring efficient and high-quality results for all aspects of production.

| Rapid prototyping | Bridge Production | Massive Production |

|---|---|---|

| Smaller Tool Stock, More Axis | Big Tool Stock, More Axis | Bigger Tool Stock, Less Axis |

| Predominantly standard fixtures. | A few custom-made fixtures. | Custom Made Fixture |

| Highly precise with significant variance. | Highly precise with significant variance. | Accurate with slight variance. |

| Very expensive per Unit | expensive per Unit | Low per unit |

| LT: 1-4 business days | LT: 5-12 business days | Lead Time: 2-4 weeks |

| Capability:1-50 pcs | Capability:51-10,000 pcs | Capability:Above 10,001 pcs |

Surface Finishes for USA's Customer

Explore our wide range of surface finishes to find the perfect option that meets both your functional and aesthetic needs. With over 20 choices available, we are confident that you will find the ideal finish to elevate the look and performance of your project.

Brushing

Sand Blast

Polishing

Tumbling

Anodizing

Painting

Black Oxide

Powder Coating

Electroplating

Alodine

Passivation

Electroless Plating

Certifications & Quality Standards

Our CNC machines are designed to deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit. With advanced technology and state-of-the-art equipment, we can guarantee the highest level of quality in our machining processes. Trust us for reliable and efficient results every time.

We follow industry standard ISO 2768 tolerances.

TonZa prides itself on having an iso9001 certified quality management system, showcasing its dedication to maintaining high standards in its production processes.

This commitment to adhering to quality control procedures ensures that TonZa consistently delivers premium products to its customers.

By following stringent quality control measures, TonZa guarantees that every item produced meets strict criteria for excellence, resulting in products that are reliable and of the highest quality for its customers.

With a focus on quality control, TonZa strives to exceed customer expectations and uphold its reputation as a trusted provider of top-notch products.

Other Machining Capabilities

We offer a wide range of manufacturing services to clients in the USA, including CNC machining, high-pressure die casting, sheet metal fabrication, injection molding, vacuum casting, 3D printing, and more. Trust us to provide high-quality, reliable solutions for all your manufacturing needs.

Injection Molding

Sheet Metal Fabrication

High Pressure Die Casting

Vaccum Casting

3D Printing

CNC Machining Services Locations Near Washington, USA

Our CNC machines are engineered to deliver precision tolerances that consistently meet industry standards. With our advanced technology, we ensure accurate and seamless component fit for maximum performance. Trust in our expertise to provide top-quality results every time.

Well-known CNC machine providers in the USA

well-known CNC machining training and programs in the USA

FAQ

We’ve compiled a list of the most common inquiries regarding CNC machining services. for the USA . “If you can’t find a satisfactory answer, please contact us.“

CNC machining in the USA is a computer-controlled manufacturing process that precisely removes material from a workpiece to create custom parts. It’s widely used by American manufacturers to produce high-precision components for aerospace, automotive, medical, and other industries.

CNC machining is widely used in aerospace, automotive, medical, electronics, defense, oil & gas, and consumer products industries due to its accuracy, repeatability, and ability to produce complex parts with tight tolerances.

U.S.-based CNC machining services handle a wide range of materials, including aluminum, stainless steel, titanium, brass, copper, ABS, polycarbonate, and PEEK. These materials meet the performance and quality standards required by industries across the USA.

Typical machines include 3-axis and 5-axis CNC mills, CNC lathes, Swiss machines, EDM (Electrical Discharge Machining), and multi-axis turning centers. U.S. manufacturers often invest in advanced machinery for high precision and efficiency.

CNC machining services in the USA typically achieve tight tolerances of ±0.001 inches (±0.0254 mm), depending on the part geometry and material. Precision U.S. machine shops often meet even stricter tolerances for high-performance applications.

You can upload a 3D CAD file (STEP, IGES, STL, etc.) and 2D drawings with specific requirements to a machining service provider’s website. U.S. companies usually respond with pricing, lead time, and DFM feedback within 24–48 hours.

Reputable U.S. CNC shops often hold certifications such as ISO 9001, AS9100 (for aerospace), and ITAR registration (for defense). These ensure consistent quality and compliance with industry standards.

Standard lead times range from 3 to 10 business days for prototype and low-volume production. Rush services are also available in many U.S. machine shops for quicker delivery.

Yes, most offer post-processing such as anodizing, powder coating, bead blasting, electropolishing, black oxide, and more—ensuring your part meets both functional and aesthetic requirements.

Choosing a U.S.-based provider ensures fast communication, strict quality control, shorter shipping times, and access to skilled machinists and advanced technology. It also supports local manufacturing and supply chain reliability.