Custom Online Titanium CNC machining services for you

Titanium CNC machining services

- We work around the clock to keep your projects on schedule

- Tolerances up to ±0.0004″ (0.01mm)

- Lead times as short as 1 day.

Why Choose Titanium for CNC Machining?

Titanium is a preferred material for CNC machining because of its exceptional strength-to-weight ratio, excellent corrosion resistance, and ability to withstand extreme temperatures.

Unlike many metals, titanium offers high durability without adding unnecessary weight, making it ideal for industries such as aerospace, medical, and automotive where performance and reliability are critical. Its biocompatibility also makes it suitable for surgical implants and medical devices.

Although titanium can be more challenging to machine due to its hardness and low thermal conductivity, CNC machining ensures precision and efficiency, allowing manufacturers to fully leverage titanium’s unique properties for high-performance components.

Properties

Titanium is strong, light, and resistant to corrosion and heat. Its biocompatibility and ability to bond with bone make it ideal for medical implants, while its durability and strength-to-weight ratio ensure wide use in aerospace, medical, and sports industries.

Parameters

Titanium combines high strength, low density, and corrosion resistance with excellent biocompatibility. Durable, non-toxic, and heat-resistant, it is widely used in aerospace, medical, and automotive industries for reliable performance.

Precautions

When machining titanium, ensure proper cooling, sharp tools, ventilation, and protective gear. Control cutting speeds and feeds to prevent tool wear and maintain surface quality, following guidelines for safe and efficient operations.

| Grade | Type | Common Name | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Density (g/cm³) | Key Features | Common Applications |

|---|---|---|---|---|---|---|---|---|---|

| 1 | CP | Commercially Pure Titanium Grade 1 | ~240 | ~170 | ~24–28 | ~70 | 4.51 | Softest, highly ductile, excellent corrosion resistance | Chemical processing, marine, medical |

| 2 | CP | Commercially Pure Titanium Grade 2 | ~345 | ~275 | ~20 | ~80 | 4.51 | Good strength, corrosion-resistant, better formability than alloys | Aerospace, automotive, medical |

| 3 | CP | Commercially Pure Titanium Grade 3 | ~450 | ~380 | ~18 | ~90 | 4.51 | Higher strength, less ductility, still corrosion-resistant | Industrial applications, marine |

| 4 | CP | Commercially Pure Titanium Grade 4 | ~550 | ~480 | ~15 | ~100 | 4.51 | Strongest CP grade, moderate formability | Surgical hardware, aerospace |

| 5 | Alloy | Ti-6Al-4V (Grade 5) | ~950–1100 | ~880 | ~10–15 | ~350 | 4.43 | Excellent strength-to-weight ratio, good corrosion resistance, most used alloy | Aerospace, biomedical, motorsports |

| 23 | Alloy | Ti-6Al-4V ELI (Extra Low Interstitial) | ~860 | ~795 | ~14 | ~340 | 4.43 | Higher purity than Grade 5, better ductility and fracture toughness | Medical implants, aerospace |

| 7 | Alloy | Ti-0.2Pd | ~370 | ~275 | ~20 | ~80 | 4.51 | Excellent corrosion resistance in reducing acids | Chemical processing |

| 9 | Alloy | Ti-3Al-2.5V | ~620 | ~500 | ~10–15 | ~250 | 4.48 | Good cold formability, moderate strength | Aerospace tubing, bicycle frames |

| 12 | Alloy | Ti-0.3Mo-0.8Ni | ~500 | ~400 | ~18 | ~160 | 4.54 | Excellent corrosion resistance, especially in acidic environments | Heat exchangers, paper & pulp industry |

Why Titanium is hard for CNC machining?

Titanium is considered difficult to machine with CNC for several reasons, despite its many desirable properties (such as strength, corrosion resistance, and light weight).

Low Thermal Conductivity

High Strength and Hardness

....

Advantages of machining titanium alloys in Tonza

Machining titanium alloys can be exceptionally demanding, but Tonza leverages advanced capabilities to turn this challenge into an advantage for your business. Here are the key advantages of machining titanium alloys with Tonza:

Expertise in Difficult-to-Machine Materials

Advanced 5-Axis CNC Capabilities

....

Why Choose ours Titanium CNC machining services?

Each component is fabricated to tight tolerances of ±0.01 mm, delivering a flawless match to blueprint.

Tonza work with reliable raw material providers to provide excellent quality materials for your items.

Obtain rapid and precise DFM assessments to improve your design for production and expedite output.

With deep industry knowledge, we deliver reliable the material CNC manufacturing services.

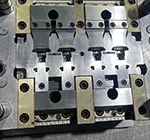

Capabilities of Titanium CNC machining services

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

Tolerances

±0.05mm

Sophisticated technological craftsmanship to provide you with top-tier product performance.

Max part size

500 mm x 500 mm

Premium-grade tech solutions to provide you with premium-grade manufacturing output.

Min part size

5 mm x 5 mm

Comprehensive hands-on skills, expertise in producing advanced components.

Lead Time

< 10 days

Streamlined internal workflows, and lean operations with minimal downtime

Surface Finish

Ra 0.8-1.6 µm

Well-coordinated team supervision, and optimized output.

Wall Thickness

0.75 mm

Deep industry knowledge, expertise in producing sophisticated components.

Overcoming Challenges in Titanium Machining

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in CNC machining.

Advanced Tooling and Cutting Parameters

We provide CNC machining for titanium using advanced tooling and precise cutting parameter control. This ensures high-quality, accurate components with excellent surface finish for demanding industries.

Cooling and Heat Management Techniques

By effectively controlling temperature during machining, we prevent overheating, reduce tool wear, and maintain precision, ensuring high-quality, durable components for aerospace, medical, and other demanding applications.

Skilled Machinists with Titanium Expertise

We provide CNC machining for titanium with skilled machinists who ensure precise cutting and high-quality components for aerospace, medical, and other demanding applications.

Commonly Used Titanium Types

Our CNC systems provide exact limits that satisfy industry norms, securing reliable accuracy and perfect part fit.

| Titanium Grade | Common Name | Type | Main Feature | Typical Applications |

|---|---|---|---|---|

| Grade 1 | CP Titanium Grade 1 | Commercially Pure | Softest titanium, highly formable, excellent corrosion resistance | Chemical processing, marine, medical |

| Grade 2 | CP Titanium Grade 2 | Commercially Pure | Balance of strength, formability, and corrosion resistance | Aerospace, automotive, industrial |

| Grade 3 | CP Titanium Grade 3 | Commercially Pure | Higher strength than Grades 1–2, still corrosion-resistant | Pressure vessels, marine, aerospace |

| Grade 4 | CP Titanium Grade 4 | Commercially Pure | Strongest CP titanium, reduced formability | Medical implants, aerospace |

| Grade 5 | Ti-6Al-4V | Titanium Alloy | Most commonly used alloy, excellent strength-to-weight ratio | Aerospace, motorsports, medical | Grade 23 | Ti-6Al-4V ELI | Titanium Alloy | Medical-grade version of Grade 5, better fracture toughness | Surgical implants, orthopedic devices | Grade 7 | Ti-0.2Pd | Titanium Alloy | Superior corrosion resistance, especially in reducing acids | Chemical and desalination plants | Grade 9 | Ti-3Al-2.5V | Titanium Alloy | Good cold formability and moderate strength | Tubing, aerospace frames, bicycles | Grade 12 | Ti-0.3Mo-0.8Ni | Titanium Alloy | High corrosion resistance and strength, good weldability | Heat exchangers, power generation |

Surface Treatment of Titanium

Tonza equip with a wide variety of CNC materials for custom-machined components, including steel, plastics, cooper, brass, aluminum, and over 100 other materials.

Brushing

Polishing

Tumbling

Anodizing

Black Oxide

Electroplating

Powder Coating

Alodine

Passivation

Electroless Plating

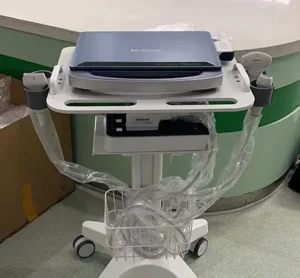

Application Industries of Titanium

From transportation to aviation, Tonza’s CNC manufacturing fulfills the exact needs of multiple industries. We partner with independent innovators, designers, and large-scale businesses, serving over 1,000 partners worldwide.

Choice Other Metal Materials Machining

Tonza’s CNC machining services ensure industry-standard precision tolerances for uniform accuracy and perfact component alignment.

Brass CNC machining services

Cooper CNC Machining Service

Aluminum CNC Machining Service

Stainless Steel CNC Machining Services

Mild Steel CNC Machining Services

Magnesium CNC Machining Services

Titanium CNC Machining Services

Choice Other Plastics Materials Machining

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

ABS CNC machining services

PMMA CNC Machining Service

Nylon CNC Machining Service

PC CNC Machining Service

PP CNC Machining Services

PET CNC Machining Services

PEI CNC Machining Services

POM CNC Machining Services

PTFE CNC Machining Services

PEEK CNC Machining Services

HDPE CNC Machining Services

UHMW CNC Machining Services

FAQ about Titanium

We’ve compiled answers to the top questions clients ask about our Titanium CNC Machining Services.

TONZA machines a wide range of titanium grades including Grade 2, Grade 5 (Ti-6Al-4V), and Grade 23, suitable for aerospace, medical, and high-performance applications.

TONZA offers advanced CNC technology, expert material handling, and precision machining expertise to deliver high-quality titanium components.

TONZA routinely achieves tight tolerances of ±0.05 mm, with higher precision available depending on the part geometry and material condition.

Yes, TONZA supports rapid prototyping, low-volume production, and full-scale manufacturing for titanium components across industries.

TONZA uses optimized speeds, high-end carbide tools, proper coolant delivery, and controlled cutting strategies to manage titanium’s low thermal conductivity and work hardening.

TONZA provides finishing options like bead blasting, polishing, anodizing (for Ti), and surface passivation to meet functional and aesthetic requirements.

Yes, TONZA’s multi-axis CNC machining centers can handle intricate titanium features such as deep cavities, thin walls, and undercuts.

TONZA serves aerospace, medical, defense, motorsport, and energy industries, where titanium’s strength and corrosion resistance are essential.

TONZA provides high-precision internal and external threading, including standard and custom thread types, for titanium components.

Lead times at TONZA typically range from 7 to 14 business days, depending on part complexity, quantity, and finishing requirements.

TONZA accepts files in STEP, IGES, STL, DWG, and DXF formats, enabling smooth quoting and production processes.

Yes, TONZA can provide material traceability and certification, especially for aerospace and medical-grade titanium components.

TONZA uses CMM inspection, in-process checks, and final quality control measures to ensure titanium parts meet strict dimensional and material standards.

To get started, upload your CAD files to the TONZA website, select titanium as your material, and receive a customized quote within 24 hours.