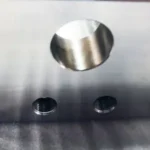

Custom Online Stainless Steel CNC machining services for you

Stainless Steel CNC machining services

- We offer continuous production to meet tight deadlines

- Tolerances up to ±0.0004″ (0.01mm)

- Lead times as short as 1 day.

Overview of Stainless Steel in manufacturing

Tonza’s Tailor-made Online Stainless Steel CNC Milling Service delivers accurate manufacturing for Stainless Steel parts, guaranteeing superior precision and performance. Using cutting-edge CNC technology, we expertly machine challenging designs while delivering fast turnaround times and tailored solutions crafted to match your precise application needs.

Properties

Stainless steel is a corrosion-resistant alloy with a high strength-to-weight ratio, making it ideal for various applications. It is easy to clean, retains its luster, and has excellent heat resistance. Stainless steel is also durable, sustainable, and recyclable, making it an environmentally friendly choice for many industries.

Parameters

The main parameters to consider include its composition (typically containing iron, chromium, and nickel), its durability, heat resistance, and non-reactivity with other substances. Stainless steel is known for its low maintenance requirements and aesthetic appeal, making it a popular choice in industries such as construction, automotive, and aerospace.

Precautions

When machining stainless steel, always wear appropriate protective gear including goggles and gloves. Use cutting tools specifically designed for stainless steel to prevent tool breakage. Work at a slower speed to avoid overheating the material and causing warping. Use a coolant or lubricant to reduce friction and extend tool life.

Why Stainless steel is ideal for CNC machining?

Stainless steel is ideal for CNC machining due to its excellent material properties that make it highly suitable for precision manufacturing processes. This metal is known for its high strength, corrosion resistance, and durability, making it a popular choice for a wide range of applications in various industries. Stainless steel also has excellent machinability characteristics, allowing for accurate and efficient CNC machining operations. Its resistance to heat and wear further enhances its suitability for CNC machining, ensuring consistent and high-quality results.

Benefits of working with Stainless steel at TONZA

Working with stainless steel at TONZA offers numerous benefits for our clients. Stainless steel is known for its durability, corrosion resistance, and aesthetic appeal, making it an ideal choice for a variety of applications. Whether you are working on a commercial kitchen project, industrial equipment, or architectural design, stainless steel provides a sleek and modern finish that is easy to maintain and clean. Additionally, stainless steel is environmentally friendly as it is fully recyclable, making it a sustainable choice for your projects.

Why Choose ours Stainless Steel CNC machining services?

Each part is fabricated to precise tolerances of ±0.01 mm, guaranteeing a flawless alignment to specification.

Tonza work with trusted raw material providers to offer high-quality grade resources for your components.

Receive quick and precise DFM reviews to improve your blueprint for fabrication and expedite output.

With in-depth market understanding, we offer dependable the substance CNC machining solutions.

Capabilities of Stainless Steel CNC machining services

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

Tolerances

±0.05mm

Sophisticated technological craftsmanship to provide you with reliable quality you can trust.

Max part size

500 mm x 500 mm

Premium-grade tech solutions to provide you with top-tier product performance.

Min part size

5 mm x 5 mm

Comprehensive practical skills, expertise in producing sophisticated elements.

Lead Time

< 10 days

Streamlined internal workflows, and optimized workflow for speed and quality

Surface Finish

Ra 0.8-1.6 µm

Efficient team management, and maximized production.

Wall Thickness

0.75 mm

Deep industry knowledge, capable of handling complex manufacturing challenges.

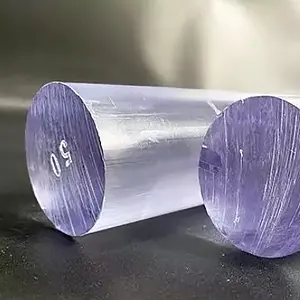

Stainless Steel Material Properties

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in CNC machining.

| Grade | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Thermal Conductivity (W/m·K) | Magnetic | Corrosion Resistance |

|---|---|---|---|---|---|---|---|---|

| SUS201 | 7.90 | 785 | 275 | 45 | 210 | 15.0 | Slight | Good |

| SUS303 | 7.85 | 620 | 240 | 50 | 190 | 16.3 | Non-magnetic | Moderate |

| SUS304 | 7.93 | 600 | 215 | 40 | 201 | 16.2 | Non-magnetic | Excellent |

| SUS304L | 7.93 | 586 | 170 | 40 | 170 | 16.2 | Non-magnetic | Excellent |

| SUS316 | 7.98 | 620 | 290 | 40 | 217 | 16.3 | Non-magnetic | Excellent (marine) |

| SUS316L | 7.98 | 579 | 170 | 40 | 150 | 16.3 | Non-magnetic | Excellent (marine) |

| SUS317 | 7.98 | 620 | 275 | 30 | 217 | 15.6 | Non-magnetic | Better than 316 |

| SUS321 | 7.92 | 620 | 290 | 40 | 217 | 16.2 | Non-magnetic | Excellent (high-temp) |

| SUS309 | 7.98 | 620 | 310 | 45 | 217 | 14.2 | Non-magnetic | Very Good (high-temp) |

| SUS310 | 7.98 | 620 | 275 | 40 | 217 | 14.2 | Non-magnetic | Excellent (high-temp) |

| SUS410 | 7.75 | 480 | 270 | 20 | 183 | 24.9 | Magnetic | Moderate |

| SUS420 | 7.75 | 700 | 345 | 15 | 223 | 24.9 | Magnetic | Good (hardenable) |

| SUS430 | 7.70 | 450 | 205 | 22 | 183 | 26.0 | Magnetic | Good |

| SUS431 | 7.75 | 850 | 520 | 20 | 248 | 24.0 | Magnetic | Good |

| SUS440A | 7.68 | 760 | 450 | 25 | 250 | 24.0 | Magnetic | Moderate |

| SUS440C | 7.75 | 760 | 450 | 14 | 270 | 24.0 | Magnetic | Moderate |

| SUS630 (17-4PH) | 7.75 | 1170 | 1000 | 17 | 330 | 18.0 | Magnetic | Excellent |

| SUS904L | 7.95 | 710 | 220 | 35 | 150 | 13.0 | Non-magnetic | Superior |

| SUS2205 (Duplex) | 7.80 | 800 | 550 | 25 | 250 | 19.0 | Slight | Superior |

Commonly Used Stainless Steel Types

Our CNC machines provide precision specifications that conform to sector standards, ensuring uniform exactness and seamless piece alignment.

| Grade | Machining Type | Cutting Speed (Vc)<br>(m/min) | Feed Rate (f)<br>(mm/rev) | Depth of Cut (ap)<br>(mm) | Tool Material |

|---|---|---|---|---|---|

| SUS303 | Turning | 140 – 180 | 0.1 – 0.3 | 1.0 – 3.0 | Carbide (CVD/Coated) |

| SUS304 | Turning | 80 – 120 | 0.1 – 0.3 | 1.0 – 2.5 | Carbide/Coated |

| SUS316 | Turning | 60 – 100 | 0.1 – 0.25 | 1.0 – 2.0 | Carbide (TiAlN) |

| SUS420 | Turning | 60 – 110 | 0.05 – 0.3 | 0.5 – 2.0 | Carbide |

| SUS430 | Turning | 80 – 140 | 0.1 – 0.3 | 1.0 – 3.0 | Carbide |

| SUS440C | Turning | 40 – 80 | 0.05 – 0.2 | 0.5 – 1.5 | Carbide/Coated |

| SUS630 | Turning | 90 – 140 | 0.1 – 0.25 | 0.5 – 2.0 | Carbide |

| SUS304 | Milling | 60 – 120 | 0.05 – 0.2/tooth | 0.5 – 2.0 | Carbide/Coated |

| SUS316 | Milling | 50 – 100 | 0.05 – 0.15/tooth | 0.5 – 1.5 | Carbide/Coated |

| SUS440C | Milling | 40 – 70 | 0.03 – 0.1/tooth | 0.3 – 1.0 | Carbide/Coated |

Surface Treatment of Stainless Steel

Tonza ensure a wide range of CNC materials for individually crafted parts, including aluminum, steel, brass, plastics, and over 100 other materials.

Brushing

Polishing

Tumbling

Anodizing

Black Oxide

Electroplating

Powder Coating

Alodine

Passivation

Electroless Plating

Application Industries of Stainless Steel

From vehicle to aviation, Tonza’s CNC manufacturing meets the precise needs of various industries. We work with solo creators, designers, and major companies, serving over 1,000 clients worldwide.

Choice Other Metal Materials Machining

Tonza’s CNC machines provide high-standard tolerances for reliable accuracy and perfact component coordination.

Brass CNC machining services

Cooper CNC Machining Service

Aluminum CNC Machining Service

Stainless Steel CNC Machining Services

Mild Steel CNC Machining Services

Magnesium CNC Machining Services

Titanium CNC Machining Services

Choice Other Plastics Materials Machining

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

ABS CNC machining services

PMMA CNC Machining Service

Nylon CNC Machining Service

PC CNC Machining Service

PP CNC Machining Services

PET CNC Machining Services

PEI CNC Machining Services

POM CNC Machining Services

PTFE CNC Machining Services

PEEK CNC Machining Services

HDPE CNC Machining Services

UHMW CNC Machining Services

FAQ about Stainless Steel

Explore the answers to popular questions regarding our precision Stainless Steel CNC machining.

TONZA machines various stainless steel grades, including 304, 316, 303, 410, and 17-4 PH, to meet different strength, corrosion resistance, and finish requirements.

TONZA offers precision CNC technology, expert engineering support, and high-strength tooling specifically optimized for stainless steel machining.

TONZA regularly achieves tolerances of ±0.05 mm, and can provide tighter tolerances depending on geometry, grade, and application.

Yes, TONZA has the expertise and tooling to machine hardened and precipitation-hardened stainless steels, such as 17-4 PH and 410.

TONZA provides various surface finishes including brushing, polishing, bead blasting, passivation, and electropolishing for stainless steel components.

Yes, TONZA supports one-off prototypes, low-volume runs, and mid-scale production, offering flexible services to match your project stage.

TONZA uses carbide tooling, advanced coolant strategies, and optimized feeds and speeds to minimize tool wear and ensure consistent quality.

Depending on complexity and quantity, TONZA typically delivers stainless steel parts within 5 to 10 business days, with expedited options available.

TONZA provides stainless steel parts to industries such as medical, aerospace, marine, food processing, and industrial equipment.

Yes, TONZA's multi-axis CNC machines are capable of producing detailed features, thin walls, and tight radii in stainless steel parts.

TONZA offers passivation, electropolishing, and coating options to enhance corrosion resistance and surface quality of stainless steel parts.

Yes, TONZA accurately machines internal and external threads, including metric and imperial standards, directly into stainless steel components.

TONZA accepts a variety of CAD file formats including STEP, IGES, STL, DXF, and DWG for quick quoting and accurate production.

Absolutely. TONZA provides Design for Manufacturing (DFM) support to ensure your stainless steel part is optimized for cost, performance, and quality.

To get a quote, simply upload your CAD files and part requirements to the TONZA website, and our team will provide a custom quote within 24 hours.