FROM RAPID PROTOTYPING AND BATCH PRODUCTION

Custom Parts, On Demand Manufacturing

Get high-quality, quick delivery and professional engineering service from an experienced manufacturer.

Our Capabilities

TonZa provides various of manufacturing capabilities to support our customer from idea to product. We have high-efficincy factory and a reliable network, we are not only deliver high-quality component but also pass satisfaction to clients.

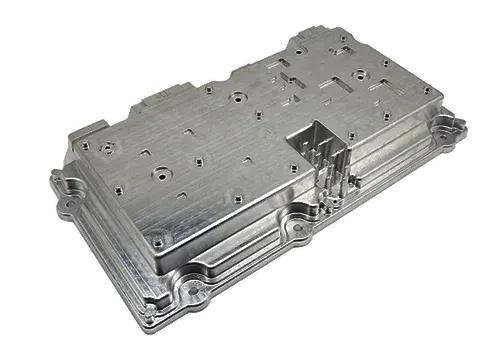

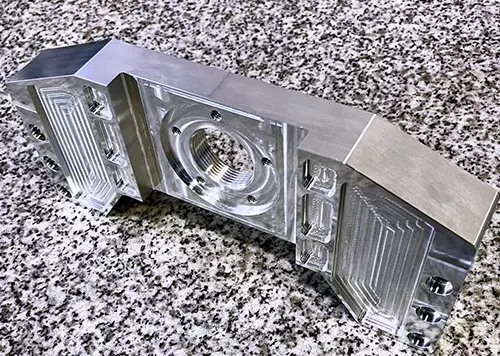

CNC Machining

We specialize in CNC milling, turning, and precision machining. Our services include producing both prototypes and end-use parts with high precision and intricate designs.

- Tolerances as tight as ±0.001 in (0.025 mm)

- Machined parts lead time 4~5 day

- Free & Automatic DFM feedback

Injection Molding

We offer plastic injection molding, rapid and production tooling, overmolding, and insert molding services, with no minimum order quantity required, all while ensuring consistent quality.

- Typically Tooling: 30 days

- Typically injection molding: 3 days

- 1 to 1M pcs

Sheet Metal Fabrication

Tonza provide laser cutting, bending, welding, punching, riveting, and stamping services, offering the flexibility to produce precise sheet metal prototypes and production parts.

- Typical leading time 3 days.

- Typically +/- 0.15mm or +/-0.006 inch

- State-of-the-Art Technologies

3D Printing

We utilize SLA, HP MJF, SLS, and SLM technologies for functional prototyping and low-volume production. Our 3D printed parts are manufactured at competitive prices.

- Tolerances as tight as ±0.2 mm

- Machined parts lead time 1 day

- Max Size: 1400x700x500mm

Die Casting

High-precision die-cast metal parts are available in aluminum, zinc, etc, ideal for high-volume production. Years of experience and specialized technology are the key to quality assurance.

- Wall Thickness 0.8 mm

- Machined parts lead time 4~5 day

- Minimum Possible Batch 1000 pcs

Vacuum Casting

Tonza offer fast and cost-effective short-run production for plastic prototypes using soft tooling, providing an excellent alternative to low-volume injection molding.

- Tolerances as tight as ±0.05 mm

- Wall Thickness 1.5mm~2.5mm

- Quantitites 25 copies per mold

Capabilities Behind Numbers

How to Work With Us

“To begin, simply select a service and upload your .stp file. Within a few hours, TonZa will provide you with an engineering analysis (DFM) and pricing. Once you approve, we’ll proceed with the manufacturing process. Your parts will be produced and delivered to you within a few days.”

Upload files

File's Format

Waiting Feedback

Evaluate

Manufacturing Start

Our Goal

Delivered

Important

About Us

“We are Shenzhen Tonza Precision Technology Co., Ltd”

Tonza was founded in 2013 and is located in Shenliang Industrial Park, Longhua District, Shenzhen, Guangdong Province, China. TONZA has a processing area of 3000 square meters. We are a customized metal parts supplier and can deliver parts within 24 hours.

To achieve rapid delivery of large quantities of parts, TONZA is equipped with 40 CNC machining centers, including 5-axis and 4-axis and imported machining centers, turning and milling machines, and a complete set of machining and production equipment, to taling more than 60 units.

To provide free service design and guarantee quantity, we have passed ISO9001:2015 and SGS on-site factory audits. Over the past 11 years, our business has expanded to 30 countries worldwide, covering fields such as military, medical, semiconductor, communication, automotive, and consumer electronics.

No matter how complex your specific structure is, or if your product encounters technical problems, we can provide you with professional services!

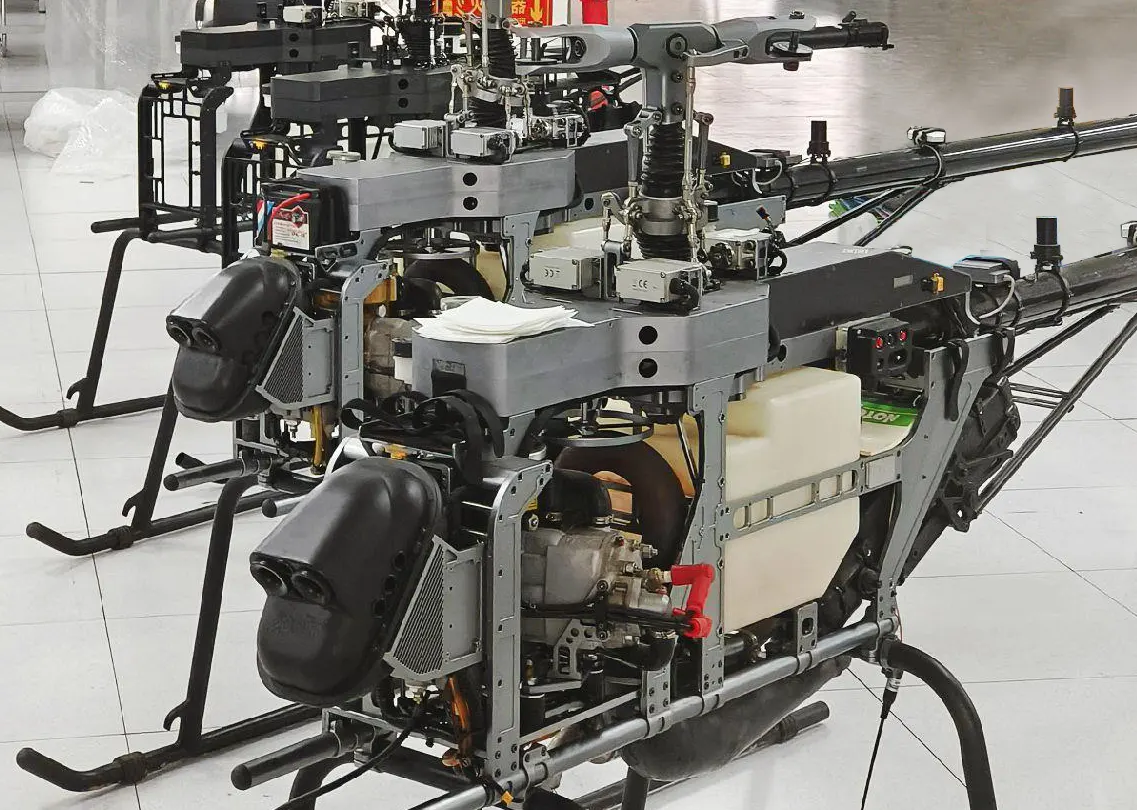

Industries Served

Our CNC machined products, molds and various products are widely used in various industries due to their excellent quality and reliable functions, and they have also become an indispensable part of many enterprises.

Aerospace

Military & Defense

Medical Devices

Communication

We simplify the manufacturing of communication devices, offering competitive pricing.

Industrial Equipment

Speed up the production of industrial equipment parts and accessories.

Consumer Products

Blog

Providing you with new insights to help you improve your business