Table of Contents

Finding the right injection molding settings for new products often demands significant time and cost. This study introduces a reinforcement learning method that uses prior knowledge to speed up optimization. An actor-critic algorithm was applied to refine both the filling and holding phases. Tests on five different products showed that settings learned from one product (pre-learning) could effectively optimize a new one (post-learning), even with differences in material, gate design, or geometry. On average, fewer than 16 cycles were needed to optimize the filling phase and fewer than 10 for the holding phase. This approach demonstrates the potential for quicker, more efficient tuning of molding parameters and supports the development of self-adjusting injection molding systems.

Editor

Richárd Dominik Párizs, Dániel Török, ZHAOPeng ZHOUHuamin LI Yang LI Dequn

Challenge of Optimizing Injection Molding Parameters

The optimization of plastic injection molding process parameters has long been a research hotspot among scholars. Many researchers have turned to injection molding simulation software for process optimization.

However, the lengthy computational time of these simulations often fails to meet the efficiency demands of actual production environments [1].

-

Surrogate Modeling: Reducing Computational Burden

To address this, scholars have developed various surrogate (agent) models to replace the time-consuming simulations.

These include neural networks [2–3], support vector machines [4], gray system theory [5], Kriging models [6], and Gaussian processes [7].

While these models significantly reduce computation time, their effectiveness relies heavily on the availability of adequate and accurate training samples.

Unfortunately, the collection of such data is both complex and labor-intensive, limiting the practical application of these models in industrial settings.

-

Artificial Intelligence in Process Optimization

In recent years, artificial intelligence (AI) methods have been widely adopted in process optimization research. For instance, Kwong et al. [8] proposed an instance-based reasoning approach to parameter setting;

Shelesh-Nezhad et al. [9] explored correction strategies within the instance reasoning process; and both He et al. [10] and Lau et al. [11] introduced fuzzy-neural models for injection process parameter setting.

Additionally, Yu Bin et al. [12] applied rule-based fuzzy reasoning to eliminate product defects, while Tan et al. [13] proposed a fuzzy multi-objective optimization method for defect correction.

-

Limitations of Existing Intelligent Approaches

However, each of these methods has inherent limitations. Case-based reasoning struggles to guarantee that the inferred parameters will yield qualified products.

Rule-based fuzzy systems depend on experienced technicians to define initial process parameters, while fuzzy-neural models demand large datasets for effective learning.

These challenges have confined much of this research to theoretical exploration rather than practical application in engineering fields.

-

Complexity of the Injection Molding Process

The core difficulty lies in the nonlinear, strongly coupled, and time-varying nature of the relationship between process parameters and product quality in injection molding.

This complexity makes it challenging to establish precise mathematical models.

Consequently, the problem domain is characterized by weak theoretical underpinnings and strong reliance on empirical knowledge.

AI and soft computing technologies, which are designed to emulate human reasoning, offer promising solutions in such contexts [14].

-

A Hybrid Intelligent Model for Process Parameter Optimization

This paper begins with an analysis of the system characteristics inherent to the plastic injection molding process.

By integrating the strengths of case-based reasoning, surrogate modeling, and fuzzy logic, we propose a hybrid intelligent model.

This model is designed to simulate the decision-making process of skilled technicians during mold trials and serves as a framework for the intelligent setting and optimization of injection molding parameters.

-

Influencing Factors in Injection Molding Quality

The quality of molded plastic parts is influenced by numerous factors, including mold structure, processing parameters, and the production environment.

Given the characteristics of plastic materials and the complexity of injection molding equipment, the process is highly intricate.

Among all influencing factors, injection parameters play a particularly critical role in determining part quality.

-

Limitations of Experience-Based Parameter Setting

Prior to production, machines must be carefully adjusted to ensure the manufacture of defect-free parts—a process that typically consumes considerable labor and material resources.

The advent of computer-aided engineering (CAE) has mitigated these costs by shifting the trial-and-error process to virtual simulations.

Through mold flow analysis, CAE allows for the zero-cost optimization of process parameters before actual production begins.

Nonetheless, the injection molding process involves numerous interrelated variables—such as barrel temperature, mold temperature, and injection time—each of which affects the others.

Furthermore, the quality of molded parts must be assessed across multiple indicators, which vary depending on the end-use requirements of the part. Selecting optimal parameter combinations, therefore, remains a significant challenge for manufacturers.

Relying solely on technician experience introduces several drawbacks.

First, it places high demands on the skill level of personnel.

Second, it often necessitates a large number of experimental trials to compare outcomes and draw conclusions—without providing clear insight into how each parameter affects specific quality metrics.

Third, this approach cannot predict the performance of untested parameter combinations, making it difficult to find true optimal settings.

-

Orthogonal Experiment Design: A Practical Solution

To address this, orthogonal experimental design offers a more systematic and scientific method.

By strategically designing a small set of test combinations, it is possible to capture comprehensive information, including the performance of parameter sets that have not been physically tested.

This approach eliminates random trial-and-error, enabling the identification of optimal parameter settings and highlighting the most influential factors affecting quality.

As a result, technicians can focus their adjustments on parameters that truly impact product outcomes.

Plastic analysis

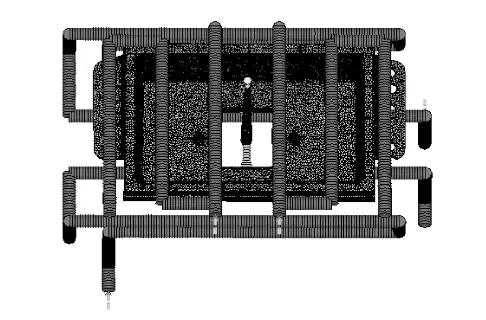

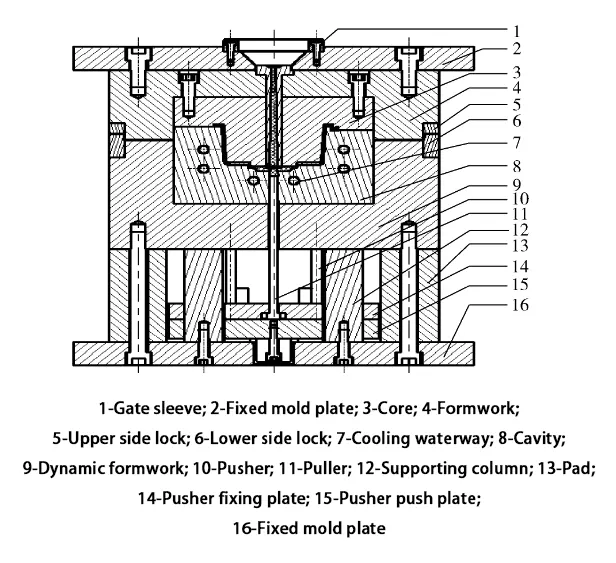

Figure 1 shows a car with an organizer box. There are depressions for loading. The surface requires smoothness and no traces, so the conventional mold structure cannot be used to avoid the pusher leaving traces on it.

To solve the mold demolding problem, but not to increase the mold structure to avoid cost increases, the use of inverted mold structure, i.e., the core installed in the fixed mold, cavity installed in the moving mold, the top of the pusher in the plastic than the surface of the surface, the use of the surface has no effect;

To ensure that the mold can follow the moving mold when the mold is opened, a grid pattern is designed on the outside of the plastic part, and the connecting force between the pattern and the cavity is used to pull out the plastic part; and the square hole in the middle is used to set up a double gate for feeding the material;

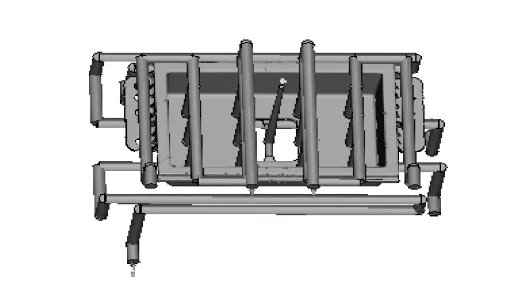

A three-dimensional cooling system is used to surround the inner and outer surfaces of the part. The mesh model established in Moldflow is shown in Fig. 2, and the material used is acrylonitrile-butadiene-styrene copolymer (ABS) of grade 728-A from Kumho Petrochemical Company in South Korea.

This material has a good luster and coloring, making it suitable for the aesthetics of automobile interior parts. It is ideal for the aesthetics of automobile interior parts.

From the point of view of the use and assembly of the organizer box, it does not need to withstand too much force, but there are specific requirements for the assembly precision, when assembling the plastic parts in the length direction, i.e., the 𝑦 direction, the 𝑥 direction and the z direction have no limitations, therefore, the volumetric shrinkage of the plastic parts and the warping deformation in the 𝑦 direction are used as the test indexes of the plastic parts, and the smaller the smaller indicates the higher dimensional precision of the plastic parts: the smaller the dimension, the higher the dimensional accuracy of the plastic part.

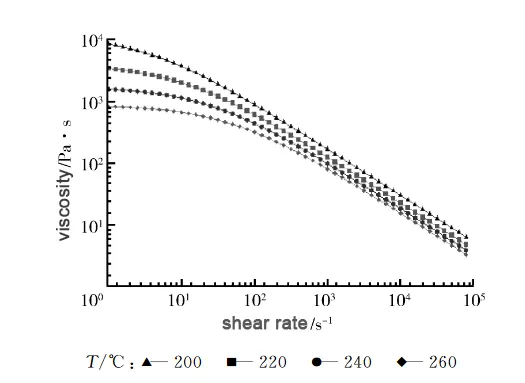

Figure 3 shows the viscosity characteristic curve of plastic materials, from which it can be seen that the plastic raw materials exhibit different viscosity characteristics at various melt temperatures and shear rates, which directly affect the melt flow filling process during injection molding.

According to the influencing factors of melt viscosity, the injection rate (characterized by injection time), mold temperature and melt temperature were taken as the test factors;

According to the influencing factors of molding shrinkage of plastic parts, the test factors included holding time, holding pressure (characterized by the percentage of injection pressure), and cooling time.

Orthogonal test

-

Design of test factors and levels

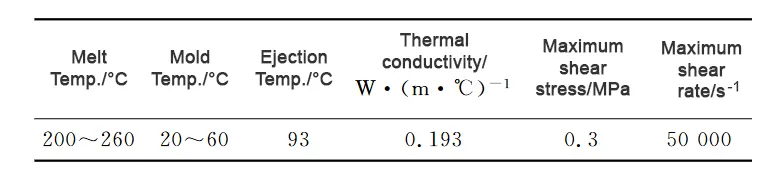

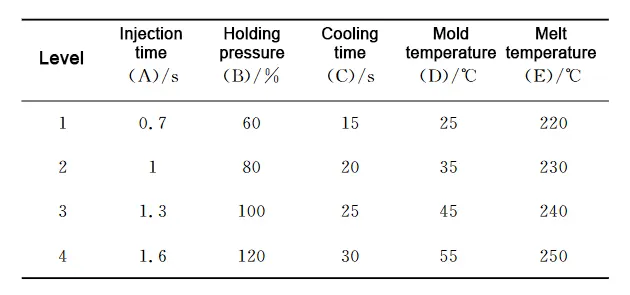

The recommended process parameters of ABS materials in Moldflow are shown in Table 1. Then according to a certain amount of simulation analysis results and practical experience, the orthogonal test factors and levels are formulated as shown in Table 2, the test factors for the melt temperature, mold temperature, injection time, holding pressure and cooling time of the five factors, divided into four levels of settings, the holding time is set at a uniform 10s.

The test standard measures volumetric shrinkage and warping deformation in the 𝑦 direction; the smaller the standard value, the better the quality of the plastic parts.

-

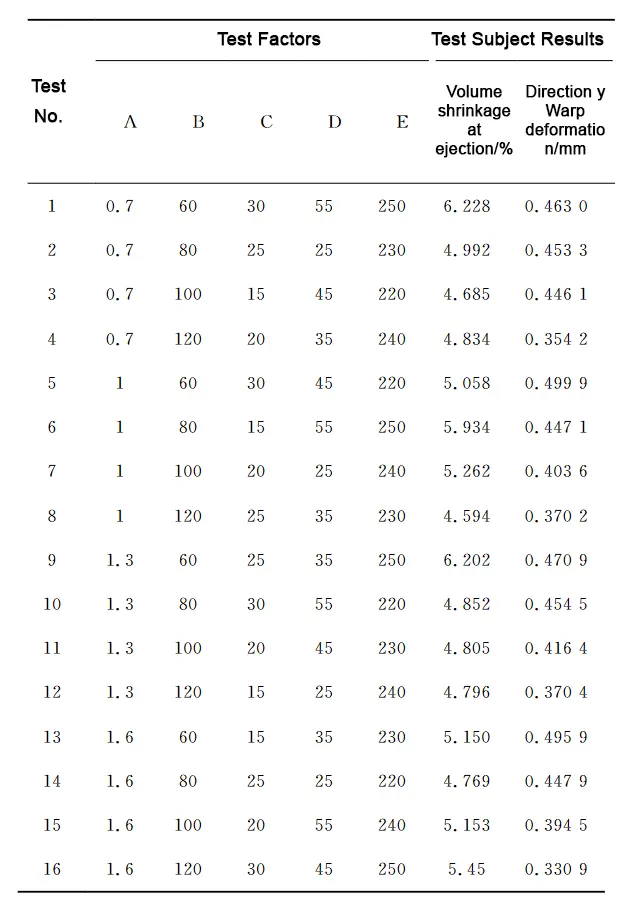

Test the factor combination program and standardized value results

According to the five-factor four-level design test factor combination L9 (33) orthogonal test table, as shown in Table 3, the results of the test standard value obtained for each row of the injection molding parameter combination scheme for CAE mode flow analysis will be recorded in Table 3 as well.

-

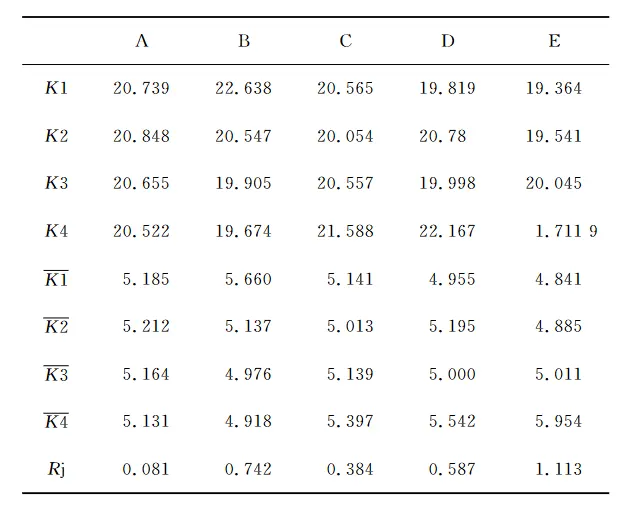

Volumetric shrinkage and its extreme difference analysis

The values of volumetric shrinkage in Table 3 are transformed into mean values and analyzed for polar deviation at different levels of factors, as shown in Table 4, to examine the effect of each factor level on the volumetric shrinkage of plastic parts.

The extreme deviation Rj in Table 4 characterizes the influence of each factor on the volume shrinkage rate of plastic parts. As can be seen from Table 4, the order of extreme deviation is as follows:

Melt temperature (1.113) > Holding pressure (0.742) > Mold temperature (0.587) > Cooling time (0.384) > Injection time (0.081).

The melt temperature had the most significant effect on the volume shrinkage rate, while holding pressure, mold temperature, and cooling time had the second most considerable effect, and injection time had the least impact.

Therefore, when the theoretical optimization value is obtained, the melt temperature and holding pressure should be fine-tuned as a priority in the actual injection molding machine, to achieve better and faster mold trial success.

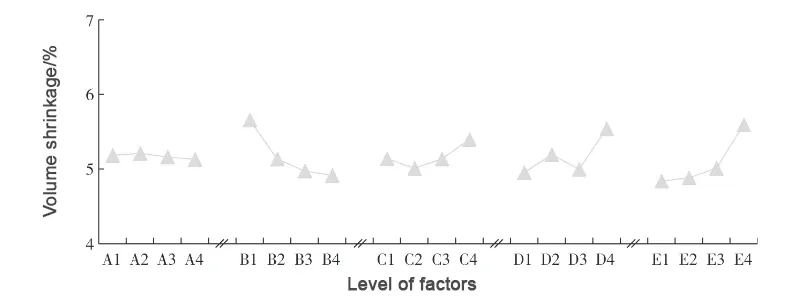

To characterize the effect of each level on the volumetric shrinkage rate, the horizontal span of each factor is taken as the horizontal coordinate of Fig. 4. The corresponding value of volumetric shrinkage rate is taken as the vertical coordinate.

The trend graph of the effect of the horizontal span of each factor on the volumetric shrinkage rate of the plastic part is drawn, as shown in Fig. 4.

As can be seen from the figure, the effect of the injection time of factor A on the volumetric shrinkage rate tends to be flat, with little impact. The volumetric shrinkage rate decreases slightly when the injection time is increased to 1.6 seconds.

The effect of injection time on the volumetric shrinkage rate of factor B is also shown in the figure.

The B factor, which is the increase in holding pressure, significantly decreases the volume shrinkage rate. This indicates that sufficient holding pressure helps reduce the volume shrinkage rate, as the rise in holding pressure makes the plastic part more compact, leading to a reduction in the shrinkage space of the plastic part.

C. The increase of cooling time leads to the decrease of volume shrinkage rate firstly and then increases, which shows that both insufficient and too long cooling time are not desirable, and the cooling time of 20s is more suitable.

D. factor mold temperature at low temperature volumetric shrinkage rate is small, when the mold temperature increases to 55 ℃, the volumetric shrinkage rate increases significantly; lower mold temperature is conducive to reducing the volumetric shrinkage rate of plastic parts.

At the same time, the volume shrinkage rate also with the E factor melt temperature increases up, in 200 ℃ to 240 ℃ when the slope is smaller, the volume shrinkage rate increases more slowly, and then continue to rise to 250 ℃, the rate of increase is larger, indicating that the melt temperature is not suitable for too high.

-

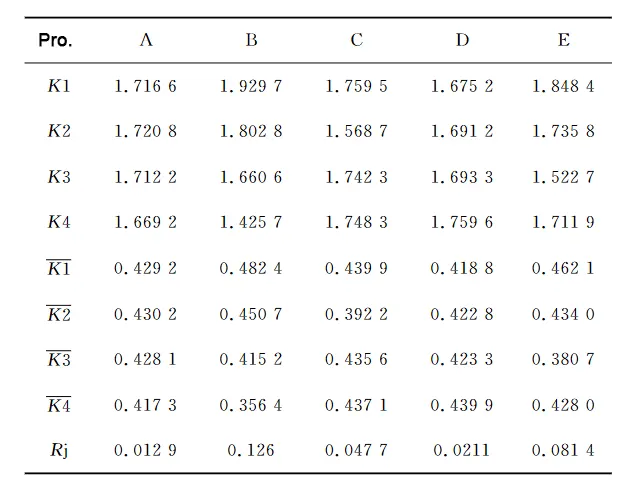

𝑦 Directional warpage deformation and its polar analysis

The storage box has assembly requirements in the 𝑦 direction, so the warpage deformation in the 𝑦 direction has higher standards, and there are no high requirements for the 𝑥 and 𝑧 directions.

The warpage deformation in the 𝑦 direction in Table 2 is transformed into a mean value and solved for the extreme deviation under different factor levels, as shown in Table 5. The impact of the various levels on the 𝑦 direction of the plastic part is then analyzed.

Table 5 analyzes the influence of each level factor on the variation of warpage deformation in the 𝑦 direction of the plastic part.

The extreme deviation Rj in Table 5 characterizes the influence of each factor on the warpage deformation of plastic parts in 𝑦 direction, and it can be seen from Table 5 that the extreme deviations are in the following order:

Holding pressure (0.126) > melt temperature (0.0814) > cooling time (0.0477) > mold temperature (0.0211) > injection time (0.0129).

Holding pressure on the 𝑦 direction of warpage deformation of the most significant impact, the influence of the melt temperature is followed by the cooling time and mold temperature, and again, the influence of the injection time is minimal.

Therefore, it is preferable to prioritize the two parameters of holding pressure and melt temperature when tuning the machine, which agrees with the tuning of volumetric shrinkage.

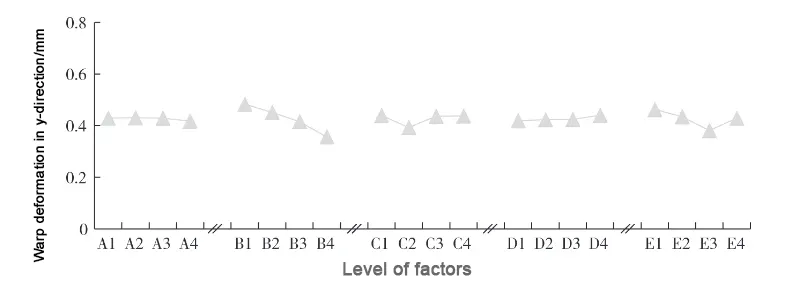

Similarly, the level span of each factor is taken as the horizontal coordinate, and the corresponding value of warpage deformation in the direction of y is taken as the vertical coordinate; the trend of change is plotted as shown in Fig. 5.

From the figure, it can be seen that the intuitive changes in the effect of the level of each factor on the amount of warpage deformation in the 𝑦 direction of the plastic part.

The curve of the A factor injection time is almost a horizontal straight line, indicating that the effect of injection time is negligible, and the decrease of warpage deformation in the 𝑦 direction with the increase of injection time is limited.

B factor holding pressure has the most significant effect, and sufficient holding pressure can significantly reduce the warpage in the 𝑦 direction, and the curve shows a decreasing trend.

C factor cooling time and E factor melt temperature on 𝑦-direction warpage deformation are both decreasing and then increasing, indicating that the cooling time of 20s and the melt temperature of 240 ℃ are the reasonable parameter choices, and both too high and too low will cause the 𝑦-direction warpage to increase;

The D factor mold temperature also has a negligible effect on the plastic parts, primarily at the D4 level, where a slight increase is observed, and overall, a small upward trend is shown, indicating a minimal increase in the trend.

Comprehensive analysis

Take the lowest point of each curve in Fig. 4 to get the process parameter combination A4B4C2D1E1 when the volume shrinkage rate is the smallest, and take the lowest point of each curve in Fig. 5 to get the process parameter combination A4B4C2D1E3 when the warping and deformation of the 𝑦 direction is the smallest, the values of the process parameter of the two cases are generally the same, but only there is a disagreement in the E factor.

From the comparison of the two figures, if E1 is chosen as the E factor, the warping deformation in the 𝑦 direction increases by (0.4621-0.3807)/0.3807 = 21.4% compared with that of E3;

If E3 is chosen as the E factor, the volumetric shrinkage increases by (5.011-4.841)/4.841 = 3.5% compared to E1.

Meanwhile, since 𝑦-directional warpage deformation is the primary factor affecting assembly accuracy, volume shrinkage is more pronounced throughout the entire body.

To summarize the above reasons, it is evident that E3 is the better choice; therefore, the optimal combination of process parameters is A4B4C2D1E3.

Because this process combination is not included in the experimental combinations in Table 3, set the corresponding parameters in Moldflow and then perform a modeling analysis to view the results, as shown in Figs. 6 to 13.

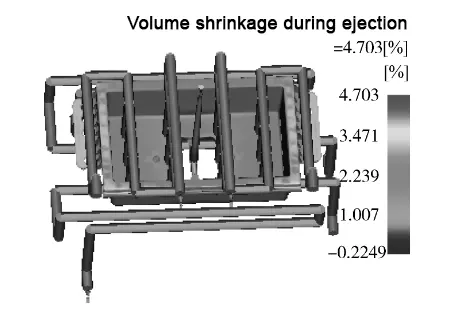

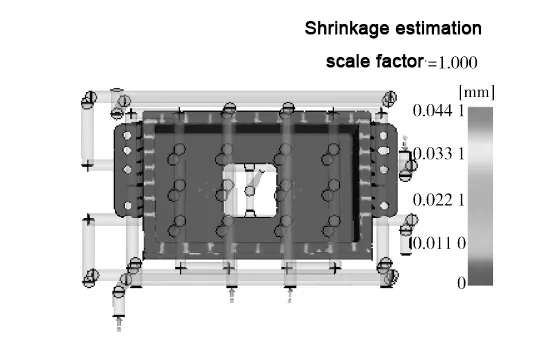

Fig.6 shows that the maximum volumetric shrinkage rate is 4.703%, which is not the smallest value in Table 2, but it is still small, and it is controlled within 5%, and the overall shrinkage rate is not significant.

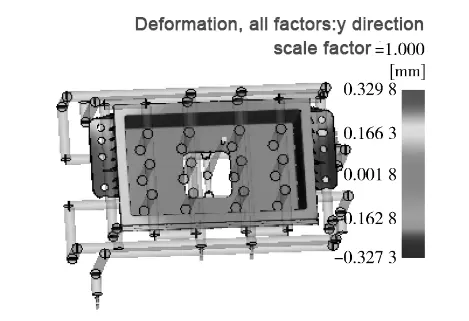

Fig. 7 shows that the maximum warpage deformation in the direction of 𝑦 under all factors is 0.3298 mm, which is smaller than the minimum value in Table 2, indicating an optimal result.

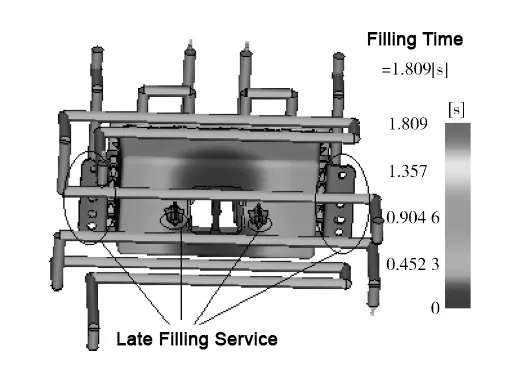

Fig. 8 Filling time shows that the latest filling place of the plastic part is at the two ears and the bottom hole, which is the thinnest part of the whole plastic part, and conforms to the principle of filling.

Fig. 9 shows the possible cavitation positions during the filling process; all of them are concentrated at the parting surface of the mold. This means that it is possible to utilize the gap of the parting surface of the mold for ventilation, or to open venting slots at the corresponding locations.

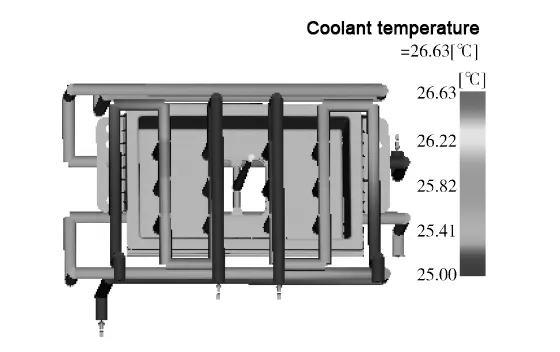

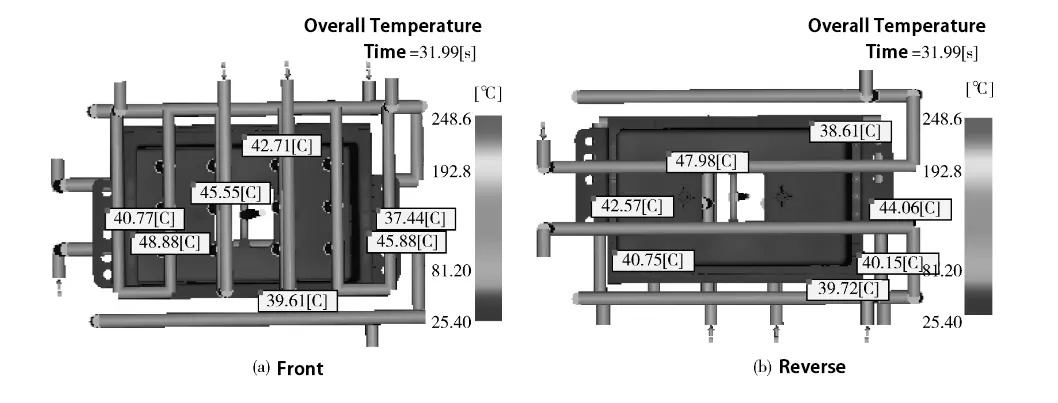

Fig. 10 shows that the estimation of cavitation indicates that the cavitation value is essentially controlled at around 40 μm, resulting in an excellent surface quality of the molded part. Fig. 11 of the circuit cooling liquid temperature shows that the temperature difference between the inlet and outlet water temperatures is 1.63 ℃;

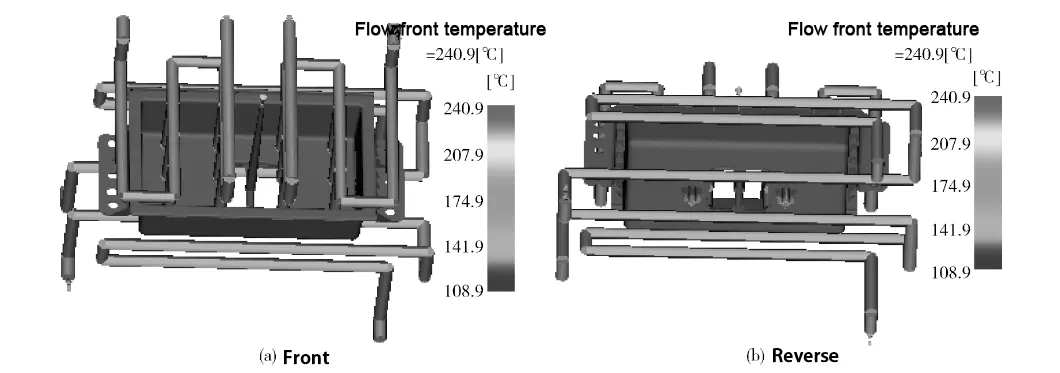

Fig. 12 shows the melt flow front temperature when filling the cavity, except for the bottom two holes of the molded part, due to the thin wal,l and the latest filling temperature is slightly lower, the other parts of the filling temperature is the same.

Fig.13 shows that the cooling of the molded part is more uniform, the temperature field distribution after pressure preservation cooling is also more uniform, the temperature difference between the inner and outer areas of the molded part is basically within 10 ℃, and the cooling effect is perfect.

Production Verification

According to the mold structure shown in Figure 14 for mold manufacturing and based on the results of the above analysis for the trial mold, the material used in South Korea Kumho 728-A grade acrylonitrile – butadiene – styrene copolymer (ABS), debugging to maintain the injection time of 1.6s, holding pressure of 120% (4.7.25MPa), cooling time of 20s, mold temperature 25 ℃ and melt temperature 240 ℃ constant. 7.25MPa), cooling time of 20s, mold temperature of 25 ℃ and melt temperature of 240 ℃ unchanged, and adjust the screw back pressure appropriately.

The production of the organizer products, as shown in Figure 15, after testing, the length of the plastic body shows a shrinkage rate of 4.82%, the width of the shrinkage rate of 4.69%, the height of the shrinkage rate of 4.71%, and the average shrinkage rate of 4.74%.

𝑦 Direction warping deformation 0.331mm, the value and the theoretical optimization value are not much different, which belongs to the reasonable deviation range, the factory inspection meets the manufacturer’s production requirements, and ensures smooth delivery.

Conclusion

(1) Through the orthogonal test and mold flow analysis on the automobile stowage box injection molding production of the tuning parameters for optimization tests, affecting the use of the stowage box assembly is mainly the volume shrinkage rate and 𝑦 direction warping deformation, the production of the best injection molding process parameter combinations are obtained as follows:

Injection time 1.6s, holding pressure 120%, cooling time 20s, mold temperature 25 ℃, and melt temperature 240 ℃, after the production of evidence, the production of products manufacturers’ smooth acceptance;

(2) Through the orthogonal test and mold flow analysis, the trend of the influence of each process parameter on the volume shrinkage rate and 𝑦-directional warpage and deformation was obtained, and the results showed that the holding pressure and melt temperature were the ones that had more influence on these two plastic performance indexes, and the testing of these two parameters should be prioritized in the setting up of injection molding machine;

(3) the use of orthogonal test can be obtained for different performance indicators of various parameters of the trend, can be targeted to efficiently achieve the adjustment of a performance indicator of the parameter tuning of the plastic parts, to promote the digital design of products to drive the high quality development of low-cost innovation, in the plastics industry and mold enterprises have a wide range of popularization value.