Design Validation plays a critical role in new product development, ensuring that a robust, profitable, and successful product (or product line) can be established to secure greater market share.

Since developing new products is among the riskiest and most vital activities for a company, addressing uncertainties early is essential.

In the initial stages of development, teams often face many unknowns and inevitably make assumptions about the product, whether consciously or unconsciously.

When these design assumptions rely more on experience, subjective judgment, or guesswork rather than factual evidence, they can create significant problems once the product reaches mass production.

Such issues waste time and resources, and in severe cases, may even cause product failure.

Research in product development highlights that solving problems detected late in the process can cost up to 100 times more than addressing them in the early stages.

For this reason, this article focuses on design assumptions and their verification through design validation, using injection-molded products as a practical example.

Design Assumptions in New Product Development

Typically, the new product development process encompasses the following stages: concept generation, design, prototype testing, pilot production, mass production, and market launch.

Each phase of new product development involves uncertainties that generate numerous design assumptions.

The new product development process is essentially a cycle of formulating design assumptions to address uncertainties, followed by continuous validation—a method of progressively resolving uncertainties.

Overall, design assumptions in new product development stem from uncertainties in both customer requirements and technology.

Uncertainty in requirements arises when development teams assume they fully understand customer needs without conducting research, when customers lack the ability to articulate their needs during research, or when customer requirements themselves change rapidly.

Multiple factors lead to various market assumptions (market size, market expansion potential, market demand, product performance/features, etc.).

Technical uncertainty stems from methods and solutions not previously applied.

Development teams may not even recognize what they don’t know, or they may be uncertain whether a particular design concept or technical solution in the design phase/prototype stage can be manufactured cost-effectively and with stable quality.

Consequently, various assumptions are made: assumptions about the technical feasibility of the product, assumptions about manufacturing capabilities and quality at a given cost.

Regarding these technical assumptions born from uncertainty, development teams often rely on experience and seemingly sound theoretical analysis, leading to overconfidence.

Coupled with pressure to shorten development cycles, they rarely invest time or resources in additional validation work.

The absence or delay in design verification for technical assumptions frequently results in product issues—functional failures, reliability problems, etc.—leading to costly mold modifications/rework, substantial maintenance expenses, or even product failure.

Design Verification in New Product Development

Transitioning products developed in laboratories or R&D centers (strictly speaking, prototypes or samples) to small-scale production and then mass production frequently encounters failures and quality issues.

Before reaching commercialization, technical research, design, and process engineering rarely achieve perfection at early stages.

The solution lies in verifying design assumptions as early and comprehensively as possible during the design phase.

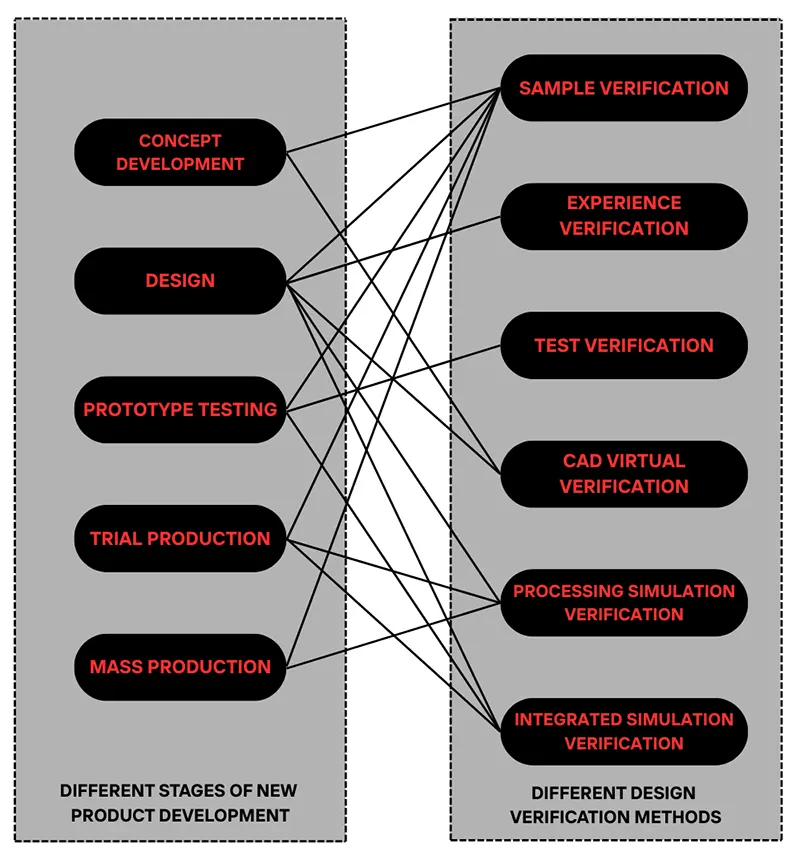

To this end, this paper summarizes design validation methods based on samples, experience, experiments, CAD, machining simulation, and integrated simulation, as shown in Figure 1, for application across different stages of product development.

Design Validation Based on Prototypes

From rapid prototyping to the latest 3D printing technologies, prototypes can be produced quickly and cost-effectively to validate product functionality and form in the early stages.

Using CAD data from the design process to create detailed prototypes for design concept validation has become a standard procedure in nearly all new product development.

IDEO takes sample-based design validation to its extreme, advocating frequent validation of design concepts using rough prototypes.

They construct these prototypes from readily available materials like cardboard and clay, ensuring specific product aspects meet requirements.

By continuously demonstrating design concepts through rough prototypes, they foster ongoing communication with customers, sales personnel, and end-users.

This approach enables rapid collection of customer feedback and swift integration of changes into the design.

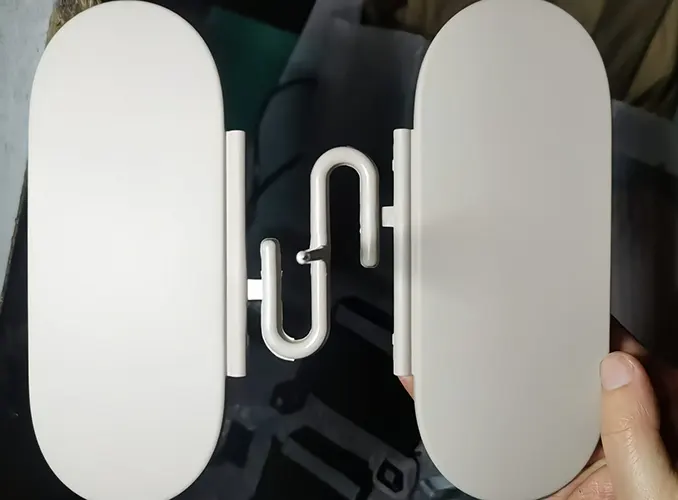

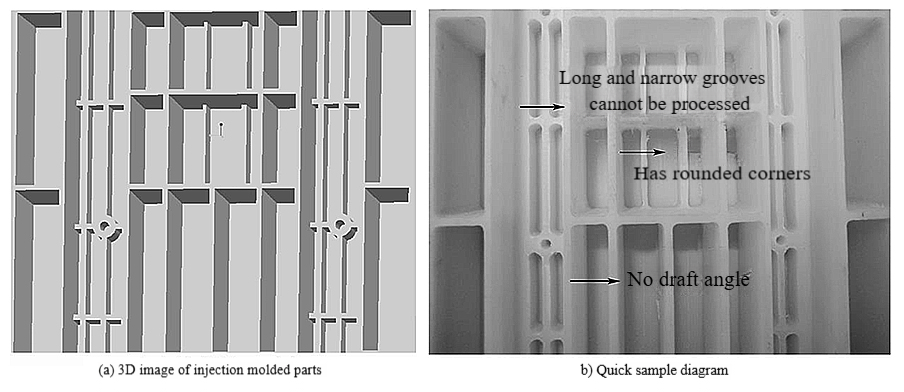

When validating design concepts with prototypes, be mindful of limitations in prototype fabrication methods.

For instance, rapid prototypes of injection-molded parts may struggle with features like draft angles, right angles, or narrow slots. Deformation and shrinkage during molding cannot be replicated, potentially affecting the final part’s shape and strength.

As shown in Fig. 2, the 3D model and rapid prototype of an injection-molded part exhibit greater stiffness than the actual part due to prototyping constraints.

This discrepancy must be fully considered when evaluating prototype stiffness and strength.

Design Validation Based on Experience

As industrial specialization deepens, many design engineers lack a comprehensive understanding of actual manufacturing methods and process challenges.

This may result in mass production difficulties or instability for designed products.

Applying concurrent engineering principles by involving production engineers earlier in the design phase enables early detection of potential design issues, significantly reducing costs.

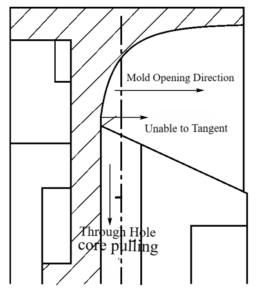

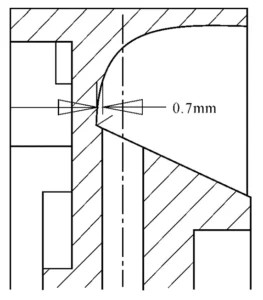

As shown in Fig. 3, the original design of this injection-molded part featured a through-hole tangent to the large mold-opening arc.

Due to potential core displacement, material ingress into the upper part of the through-hole occurred, failing to meet functional requirements.

Therefore, incorporating a clearance of approximately 0.7 mm (as illustrated in Fig. 4) ensures unobstructed through-hole flow after mold opening.

Experimental Design Validation

Material selection is critical during new product development. When lacking precedents or comparable experience, direct experimental testing remains the fastest and most reliable validation method.

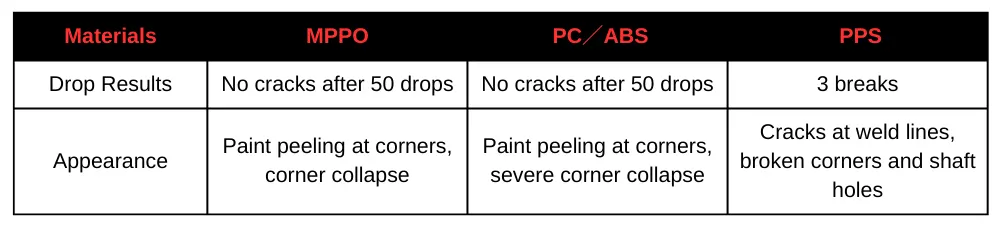

A plastic part required a certain level of impact resistance. The available plastic options included PC/ABS, MPPO, and PPS, each with distinct advantages and disadvantages in terms of cost, flow properties, and impact resistance.

To identify a suitable material within a specific cost range, an existing mold with a shape similar to the part but smaller in size was selected.

Experimental samples made from different materials were produced and subjected to free-fall impact tests.

> Test Results

Based on the test results in Table 1, the following conclusions were drawn:

- PPS: Material impact performance is too poor; not usable.

- PC/ABS: Theoretical impact strength is good; acceptable.

- MPPO: Impact resistance is acceptable.

Therefore, the pre-selected PPS material was discarded.

During new product development, it is common to design products for failure modes that will never occur.

To address such false assumptions, experiments are routinely conducted to detect false problems, thereby avoiding resource waste caused by “over-engineering” products.

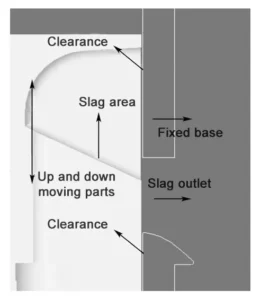

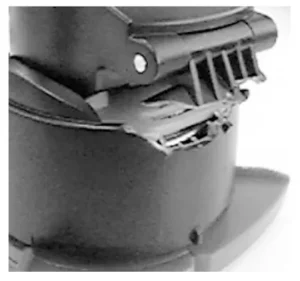

The slag discharge design for a particular product is shown in Fig. 5. To ensure slag is discharged from one direction without leakage through other moving surfaces, the combined clearance between moving surfaces of different components was strictly designed.

This resulted in extremely tight dimensional and deformation control for each part, leading to high scrap rates and susceptibility to wear. Severe wear could cause mechanism failure.

To address this issue, the development team reanalyzed the design assumptions for preventing slag leakage.

They intentionally increased assembly clearances in certain directions.

Experimental results confirmed that these enlarged clearances had no adverse effect on slag discharge while significantly reducing production precision requirements and minimizing friction and wear.

CAD-Based Design Verification

Traditional CAD software can detect interference issues during assembly by simulating the assembly of virtual products.

This is particularly crucial for externally procured mechanical parts or electronic components, where establishing a basic model is essential to determine potential interference between components.

For moving components, a motion simulation model of the mechanism should be created to check for interference among parts throughout the entire motion cycle.

This method has become a standard part of a design engineer’s workflow.

Design Verification Based on Machining Simulation

Advancements in computer technology and numerical simulation have enhanced predictive capabilities regarding part machinability in material processing (forecasting processing conditions of virtual test objects within mold environments, identifying potential manufacturing defects, etc.).

This has accelerated the adoption of simulation software across industries such as automotive, home appliances, and mold manufacturing.

Examples include sheet metal forming simulators like Dynaform and Autoform; die-casting simulators like ProCast; and plastic injection simulators like Moldflow, Moldex, and HSCAE.

Taking the plastic injection industry as an example, mold design critically influences both the successful forming of parts and their performance characteristics.

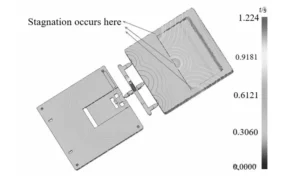

As shown in Figure 6, a single mold designed for dual parts forms two plastic components. By using the parts’ CAD models during mold design, engineers can predict whether both parts will be successfully formed.

The part on the right exhibits flow retention, which may lead to short shots. Therefore, modifying the gate location or using two separate molds is necessary.

The flexible hinge part shown in Fig. 7 utilizes thin-walled sections for bending. Simulation results indicate that the side gate design and the plastic threaded hole pillar design may create weld lines in the bending area. The presence of weld lines directly impacts bending life.

Thus, design validation through simulation technology enables early detection of design flaws, allowing zero-cost modifications that avoid mold repair expenses while enhancing bending performance.

Design Validation Based on Integrated Simulation

Manufacturers conduct final shipment inspections, including durability testing, load capacity verification, and high-temperature/high-humidity testing.

However, waiting until prototype samples are available to test these properties carries significantly higher risks.

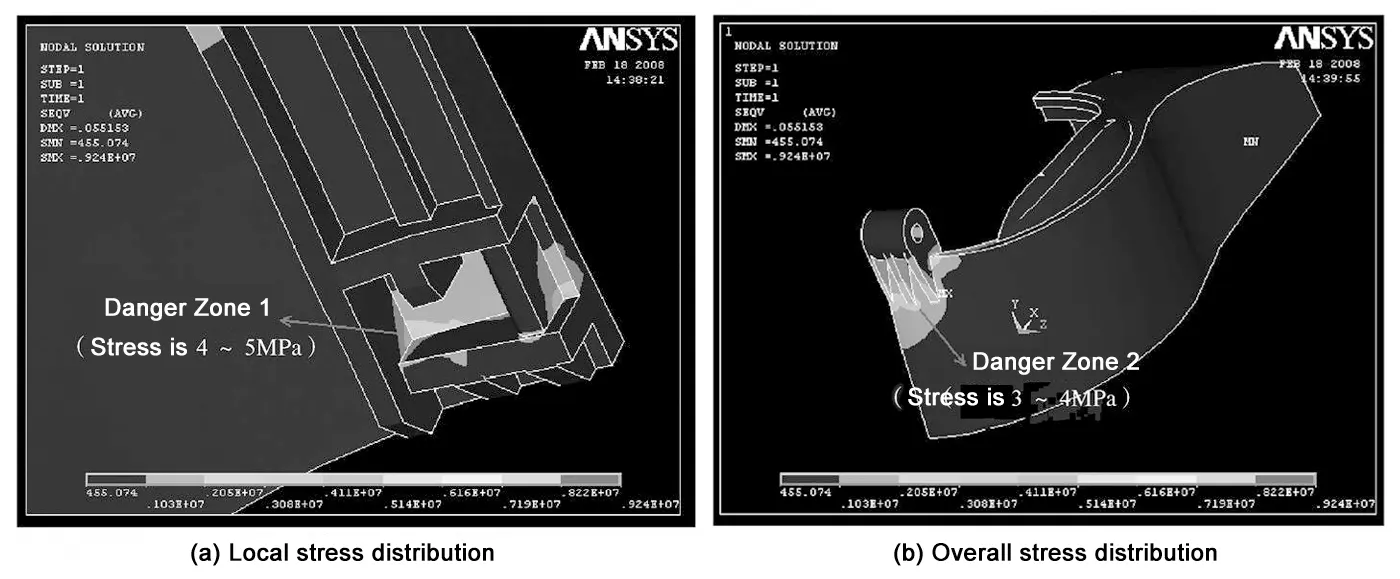

Therefore, comprehensive consideration of part strength and the impact of manufacturing processes on strength is essential. As shown in Fig. 8, the part fractured during use.

Structural strength analysis revealed that the part experienced concentrated stress in a small area.

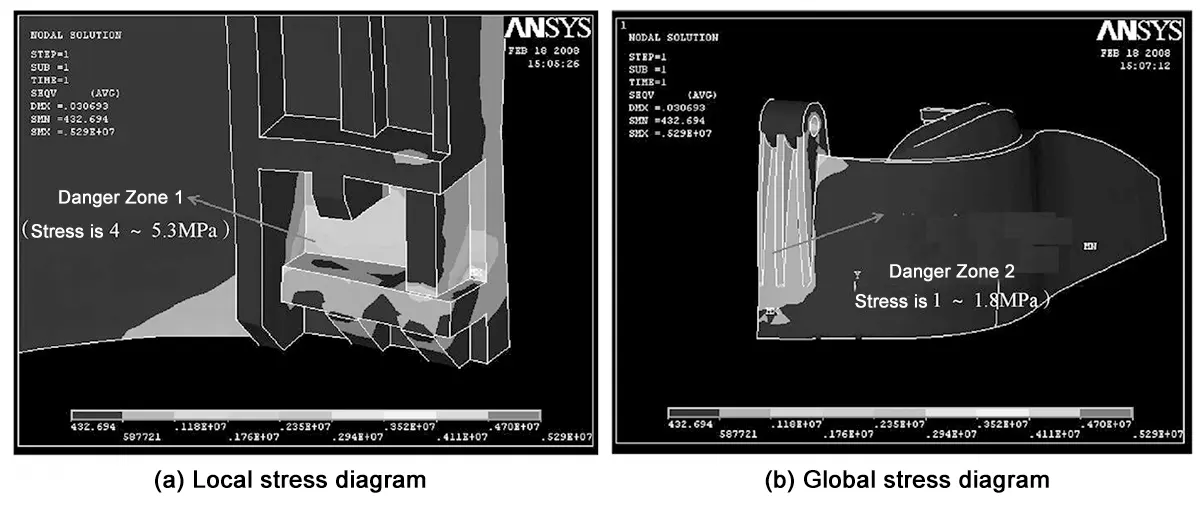

Hazardous zones are indicated in Fig. 9: Zone 1 exhibits a maximum stress of 5 MPa, while the maximum stress in the second critical zone was 4 MPa. The locations of these vital zones matched the actual fracture areas.

Under normal static loading, disregarding ANSYS’s inherent computational errors, the part’s static (design) safety factor of 8.5 appeared sufficiently safe.

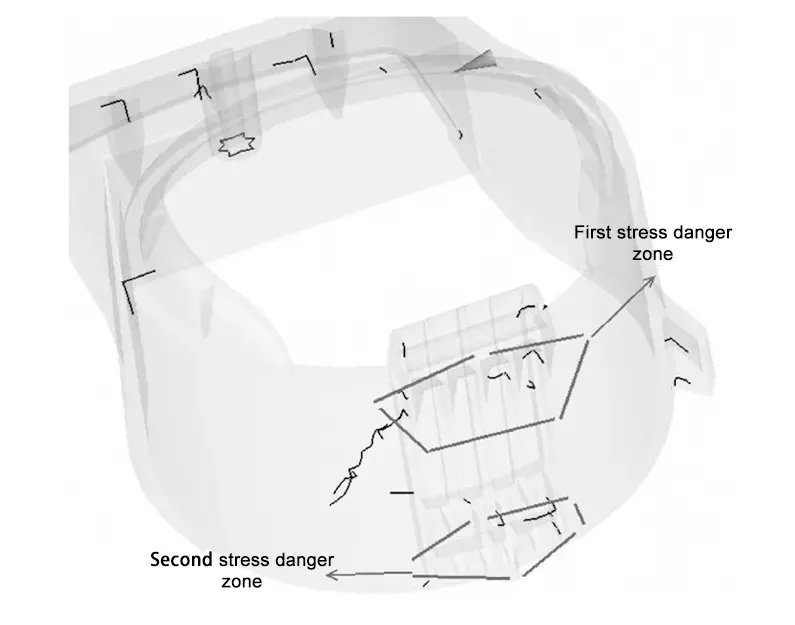

During actual injection molding, weld lines and stress concentrations exist within these two critical zones, as illustrated in Fig. 10.

Research indicates that for ductile polymers, the weld line fusion strength coefficient ranges from 0.7 to 0.8 under optimal process conditions for typical materials like POM, PP, PC, and ABS.

The presence of weld lines and stress concentrations in critical zones inherently reduces actual strength.

Combined with the difficulty of achieving optimal conditions in real molding processes, occasional overload cycles, and micro-impact stresses, these factors can cause part failure despite ample static design safety factors.

To enhance part reliability, experience-based approaches have extended rib lengths to strengthen critical zones.

However, CAE structural analysis revealed that the modified design in Region 1 (Fig. 11) exhibits a maximum stress of 5.3 MPa—more hazardous than the original design. Region 2 of the modified design is safer, with maximum stress around 1.8 MPa.

Contrary to conventional experience, CAE analysis predicted that the modified design would not yield significant improvement and was therefore not advisable.

Summary

To reduce design errors in new product development, this paper analyzes the origins of design assumptions during the development process.

Using engineering examples, specifically the development of injection-molded products, it explores various methods for validating design assumptions at different stages of new product development.

These methods include design validation based on samples, design validation based on experience, design validation based on experiments, design validation based on CAD, design validation based on manufacturing simulation, and design validation based on integrated simulation.

These validation methods can be applied at different stages of new product development.

FAQ

What is design validation in new product development?

Design validation is the process of verifying design assumptions and concepts at different stages of development to ensure that a product meets customer needs, functions reliably, and can be manufactured cost-effectively at scale.

Why is design validation important in reducing product development risks?

Without proper validation, early design assumptions may go unchecked, leading to costly modifications, mass production failures, or even complete product failure. Validating early helps companies avoid expensive late-stage rework and secure a stronger market position.

How do design assumptions affect new product development?

Design assumptions, often based on guesswork or experience rather than evidence, can create technical or market risks. If not validated, they may cause reliability issues, increased scrap rates, and financial losses once the product reaches mass production.

What are the main sources of uncertainty in product design?

Uncertainty usually comes from two areas:

Customer requirements: unclear or changing needs.

Technology: untested methods, new materials, or unproven manufacturing processes.

What are the common methods of design validation?

Design validation can be conducted through various methods, including prototypes, experimental testing, CAD modeling, machining simulation, CAE-based integrated simulation, and leveraging engineering experience.

How do prototypes contribute to design validation?

Prototypes, whether produced through rapid prototyping or 3D printing, help verify product form and function early. They enable quick customer feedback and design improvements before committing to expensive tooling or production.

What role does CAD simulation play in design validation?

CAD simulation detects potential assembly issues, motion interference, and dimensional conflicts between parts. It helps engineers resolve problems in virtual environments before moving to physical production, saving time and costs.

Why is machining or moldflow simulation critical for design validation?

Machining and injection moldflow simulations predict potential manufacturing defects, flow issues, and weld line weaknesses. These simulations allow engineers to optimize designs without costly physical trials, improving production efficiency and product quality.

How does integrated simulation improve product reliability?

Integrated simulation combines structural analysis, stress testing, and process validation to assess product performance under real-world conditions. It identifies hidden risks such as stress concentration or weld-line weakness that may not appear in theoretical models.

What are the cost benefits of early design validation?

Research shows solving problems in the design phase can be up to 100 times cheaper than fixing them after mass production begins. Early validation prevents waste, reduces mold rework, improves reliability, and accelerates time-to-market.